Mercedes-Benz has finalized the planning for a regional After-Sales Logistics Centre in Malaysia which will start operations from 2024.The German carmaker has signed a long-term lease agreement for the location and will partner with Tiong Nam Logistics Solutions Sdn Bhd to establish the new facility in Senai Airport City outside Johor Bahru.

The warehouse size of the planned location will be approximately 1,000,000 square feet. The building management system of the new warehouse will be equipped with the latest storage and material-handling systems. Operation of the facility will be by Mercedes Benz Parts Logistics Asia Pacific (Malaysia) Sdn. Bhd, a 100% subsidiary of Mercedes-Benz AG.

Part of global supply chain network

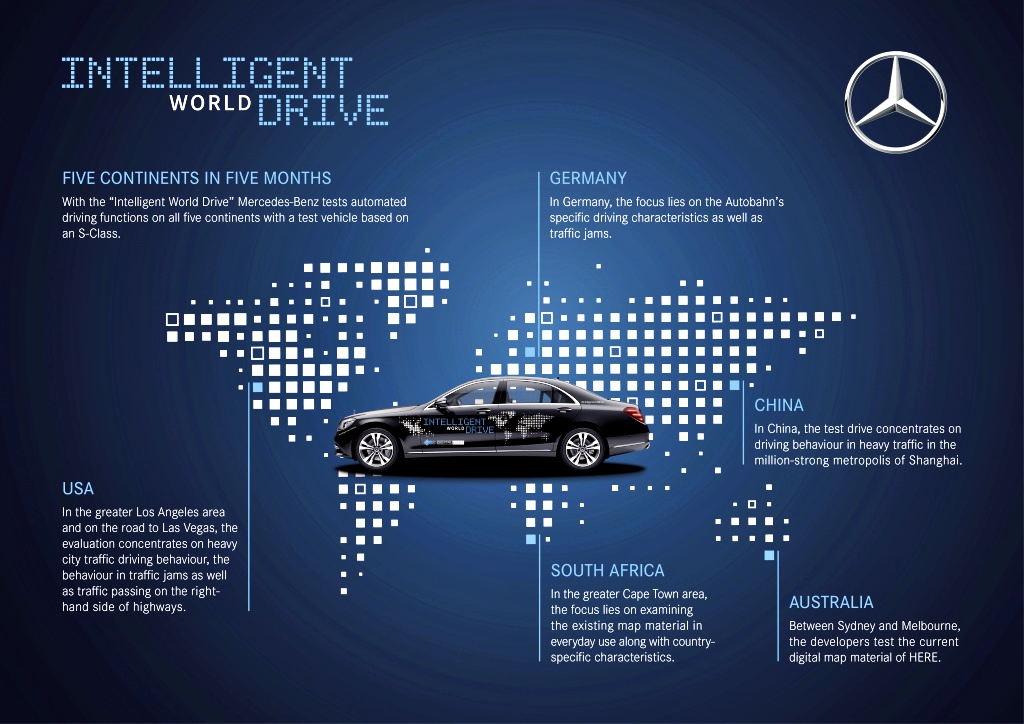

The new distribution centre will be a part of the global Daimler AG After-Sales Supply Chain Network and will serve as a distribution site for spare parts in the Asia-Pacific region and other countries. It will take care of the importation, the storage as well as the regional management of spare parts and accessories distribution.

“With our planned After-Sales Logistics Centre, Mercedes-Benz is committed and will invest to strengthen our foothold in Malaysia. We have found excellent conditions and great support in cooperation with MIDA and the related ministries. Located strategically in Johor Bahru, this new After-Sales Logistics Center will enable us to reaffirm our position as a global and regional distribution hub whilst creating new jobs for the region. Both our customers and our dealer networks will enjoy a good service and high-quality standards through this new infrastructure,” said Thomas Schulz, Vice President Global Service & Parts Operations.

Historically strategic location

Historically, Singapore’s location at the southern tip of the Malayan peninsular has made it a strategic point for trade. It served as an ideal transit point between East Asia and Europe, and even Australia, hence its development as a bustling trading port. Over the years, while Singapore has been an obvious choice for regional storage by various companies, nearby Johor has also become attractive for logistics activities.

In 2003, the BMW Group moved its regional parts storage facility from Singapore to the Port of Tanjung Pelepas (PTP) in Johor and then in 2017, it again relocated the facility to an industrial zone adjacent to Senai Airport. The facility is a logistics warehouse and parts distribution centre serving over 20 countries.

The Volkswagen Group likewise moved its regional parts facility from Singapore to PTP in 2016. It stores tens of thousands of parts for the Volkswagen, Audi, Skoda and Volkswagen commercial vehicle brands of the German group for distribution to over 20 markets.

Having a storage facility in Johor (or Singapore) is useful for the carmakers as it can speed up deliveries to customers on this side of the world. Customers will benefit as delivery times can be shortened compared to having them come all the way from Europe. The proximity to the airport as well as the port also mean that logistics can be more efficiently managed.

Upgraded Mercedes-Benz Autohaus in Johor Bahru enhances retail experience for C&C customers