Hyundai Motor Company and Kia Motors Corporation have debuted a new virtual reality (VR) design evaluation system at the brands’ global design headquarters. The new system, introduced to the Namyang Research and Development Centre in South Korea, demonstrates a heightened focus on enhancing vehicle development processes through the implementation of VR technology.

The technology uses several development applications, enabling teams of designers and engineers to carry out vehicle design quality assessments and development verification processes. It is part of the 15 billion won (about RM53 million) investment in the Namyang Research and Development Centre announced by Hyundai and Kia in March 2019.

Faster development times, reduced costs

Through the complete implementation of the virtual development processes throughout R&D and pre-production stages, Hyundai and Kia anticipate a 20% reduction in vehicle development times and a 15% reduction in annual development costs. In addition, these new virtual technologies are expected to increase profitability and trigger a cycle of continuously increasing R&D investment for Hyundai and Kia.

“The virtual development process is a necessary step for responding quickly and reacting with agility to the needs of customers and paradigm shifts within the automotive industry,” said Albert Biermann, Head of Research and Development Division for Hyundai Motor Group. “Through reinforced virtual processes, we will enhance quality and profitability, ultimately increasing investment in R&D to secure competitiveness in future mobility.”

20 simultaneous users

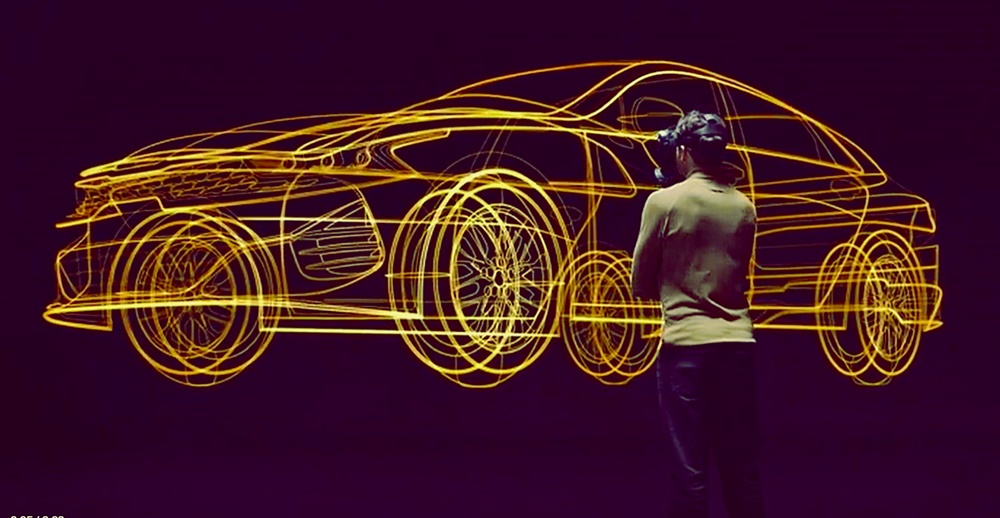

VR headsets allow the brands’ vehicle designers and engineers to virtually enter developmental simulations, with 36 motion tracking sensors detecting and tracking the locations and movement of all users, enabling each to participate accurately in real time. The new VR design evaluation system can currently support up to 20 simultaneous users, enabling greater cross-team collaboration than ever before.

As a result, the new cutting-edge facility allows the designers to more efficiently review a multitude of design concepts earlier in the developmental process and in ways that were previously physically impossible. The system simulates interior and exterior design elements, lighting, colours and materials, and even virtual environments.

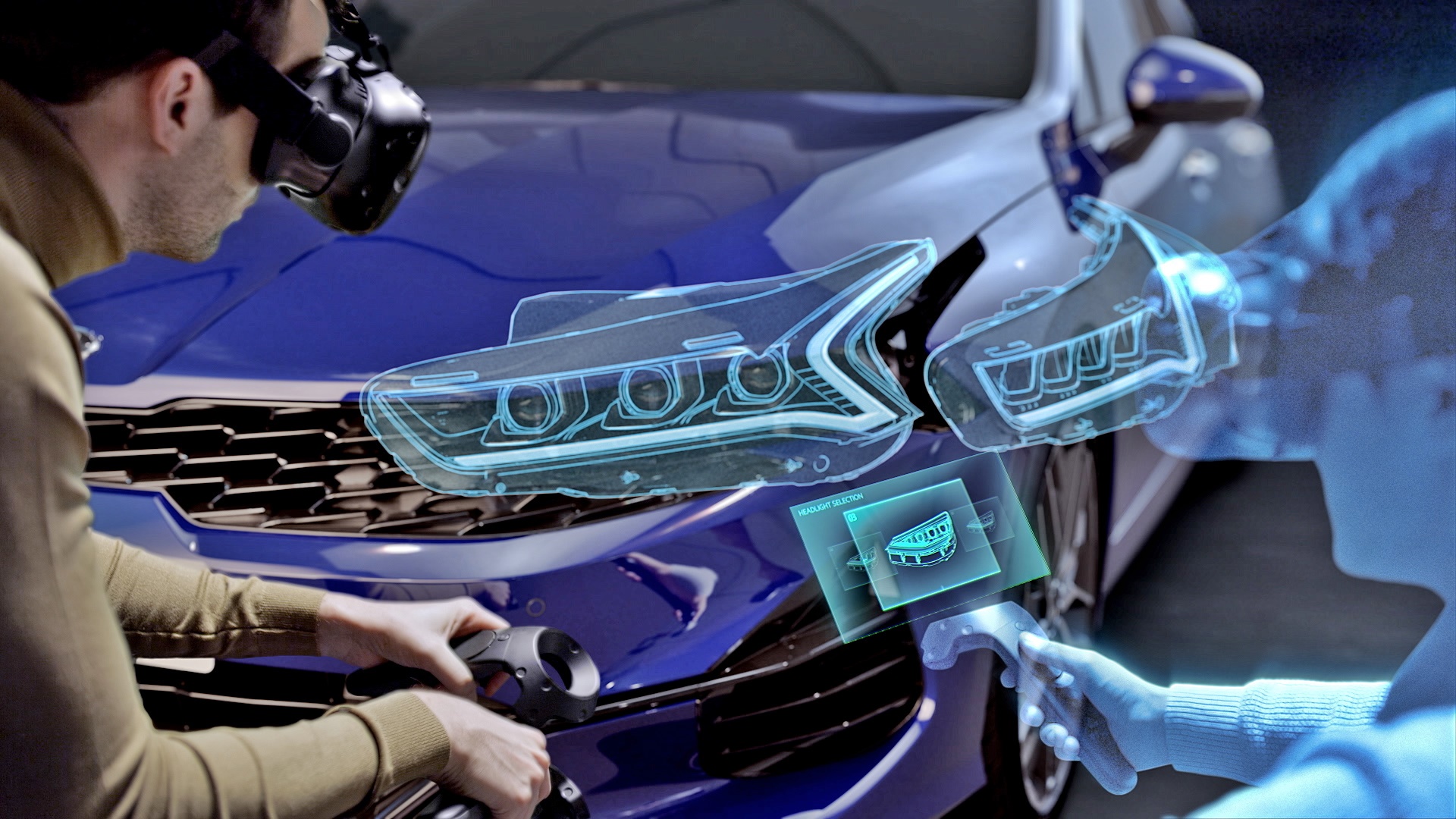

Testing individual components

VR also enables development teams to simulate operations of individual vehicle components, such as doors, bootlids, bonnets, and windshield wipers. Furthermore, the system enables testing of vehicle ergonomics and aerodynamics more efficiently.

Hyundai first used this system during the design assessment stages of the HDC-6 NEPTUNE Concept Class 8 heavy-duty truck that was revealed in October. Kia also plans to expand the design assessment capabilities of the facility for developmental use on future models.

Additionally, plans to establish remote VR design assessment capabilities will enable real-time virtual collaboration between each brand’s design centres in Europe, America, China and India, along with an enhanced virtual development process through the implementation of AR (Augmented Reality), among other technology. There are also plans to introduce VR technologies in production and assembly lines to create more ergonomic, efficient and safe working environments.

Kia’s Futuron concept is inspired by UFOs and flying saucers! (w/VIDEO)