‘Necessity is the mother of invention’ is a saying which is attributed to Plato, the Greek philosopher. And it is certainly true in these times when there is urgent need of medial equipment to save lives as well as protect healthcare personnel.

Many carmakers have initiated and executed projects to design, engineer and manufacture vital Personal Protective Equipment (PPE), doing so faster than normal processes would take. They are using their advanced technologies which can speed up the R&D, and their factories to then produce the items.

Ford, for example, is expanding its efforts to design and produce urgently needed medical equipment. In addition to the current production of more than 3 million face shields, the company is also now making powered air-purifying respirators which were designed in-house.

Gown production

To help further protect healthcare workers, Ford is leading efforts to manufacture reusable gowns with its airbag supplier, Joyson Safety Systems. The go-fast project has created reusable gowns manufactured from material used to make airbags in Ford vehicles.

Production of gowns will reach 75,000 gowns a week by Sunday and scale up to 100,000 gowns for the week of April 19 and beyond. By July 4, Joyson Safety Systems aims to cut and sew 1.3 million gowns which are washable up to 50 times, extending their usage.

Ford worked with Beaumont Health in Metro Detroit to quickly design the gown pattern and test for sizing during fit and function trials. More than 5,000 gowns have already been delivered to the hospital.

The new PAPR

Since late March, Ford manufacturing, purchasing and supply chain experts have been embedded at 3M manufacturing facilities to help increase production of urgently needed products. With this additional help, 3M and Ford were able to increase the output of Powered Air Purifying Respirators and N95 respirators at 3M’s U.S.-based manufacturing facilities.

“By working collaboratively with 3M to quickly combine more than 100 years of Ford manufacturing and engineering expertise with personal protection equipment design and expertise, we’re getting much-needed technology into the hands of frontline medical workers to help when they need it most,” said Marcy Fisher, Ford Director, Global Body Exterior and Interior Engineering.

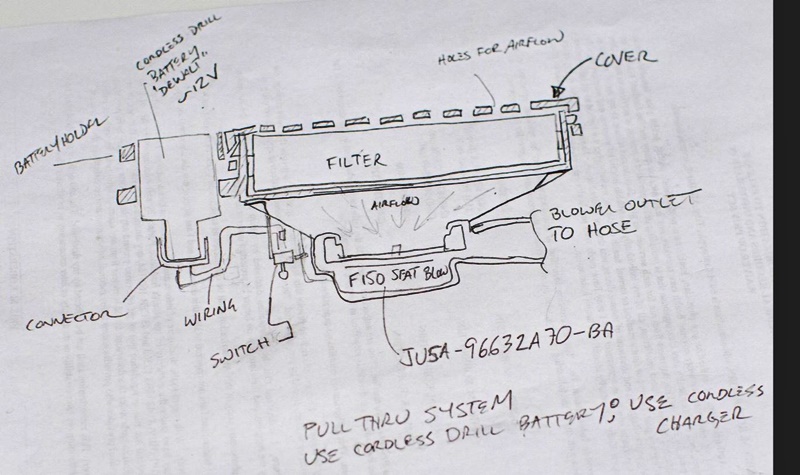

The newly designed PAPR includes a hood and faceshield to cover healthcare professionals’ heads and shoulders, while a high-efficiency filter system provides a supply of filtered air for up to 8 hours. The air blower system – similar to the fan found in F-150’s ventilated seats – is powered by a rechargeable, portable battery, helping keep the respirator in constant use by first-line defenders.

Producing globally

Besides the USA, faceshield production is also ongoing globally at Ford facilities in Canada and Thailand and with Ford joint-venture partner Mahindra & Mahindra in India. Ventilator pre-production activities are also underway in the UK, where Ford and an industry consortium are preparing to make ventilators.

Ford is providing manufacturing engineering capability, project leadership, purchasing support and assembly of the ventilators at its Dagenham engine plant. This production will help meet demand for 15,000 ventilators ordered by the U.K. government.

War on COVID-19: Proton to produce 60,000 face shields for frontliners