Just last month, Lotus confirmed it would be launching a new electric sportscar in 2026 – designated Type 135 – as part of a range of electrically-powered performance cars to be manufactured in the UK. The sportscar will have innovative new lightweight chassis technology developed through Project LEVA (Lightweight Electric Vehicle Architecture), which the carmaker mentioned last October.

Project LEVA is a research programme that’s accelerating the development of all-new lightweight structures for next-generation battery electric vehicles. The structure developed through Project LEVA will be integrated into the company’s new architecture for electric sportscars.

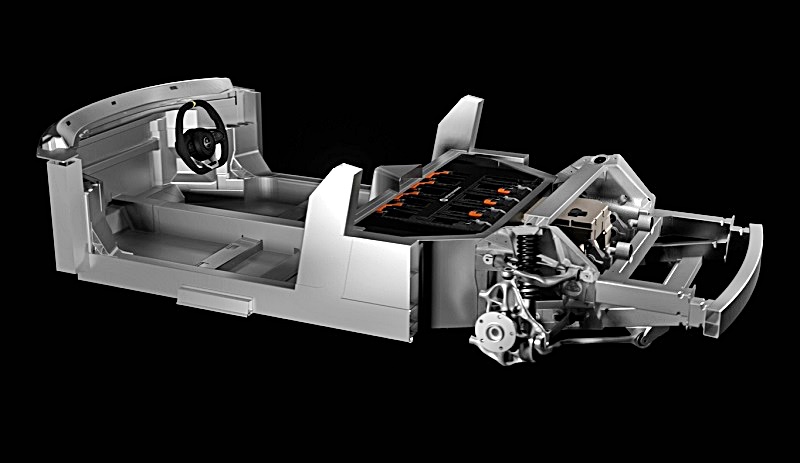

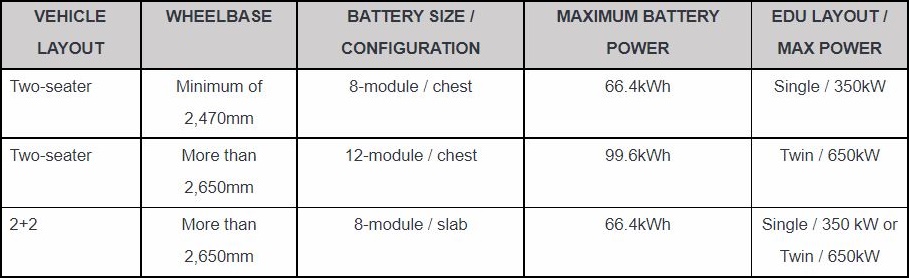

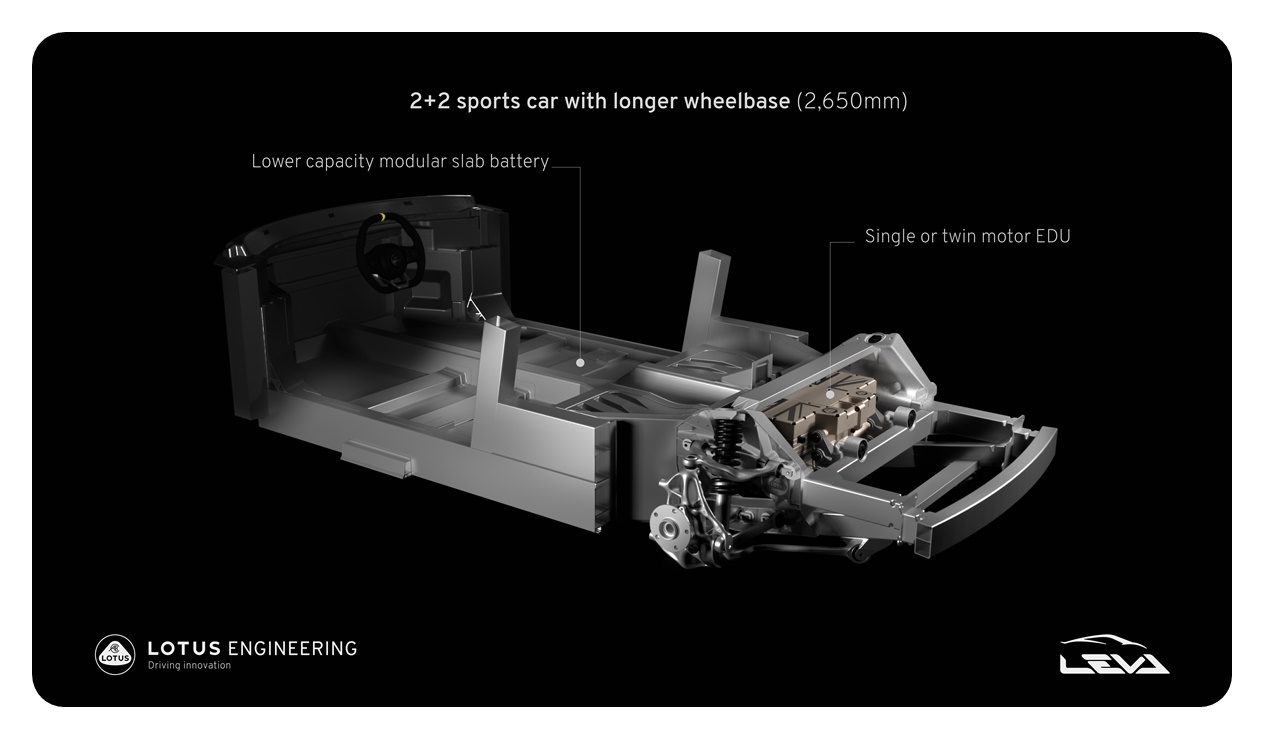

This structure represents the ‘blueprint’ for the next generation of electric sportscars, for future Lotus products, and for the Lotus Engineering consultancy to commercialise. One example of its innovation is that the rear structure is 37% lighter than it is on the Lotus Emira V6. It is fully adaptable to provide a platform for a range of vehicle types with variable layouts, wheelbase lengths, battery sizes and configurations.

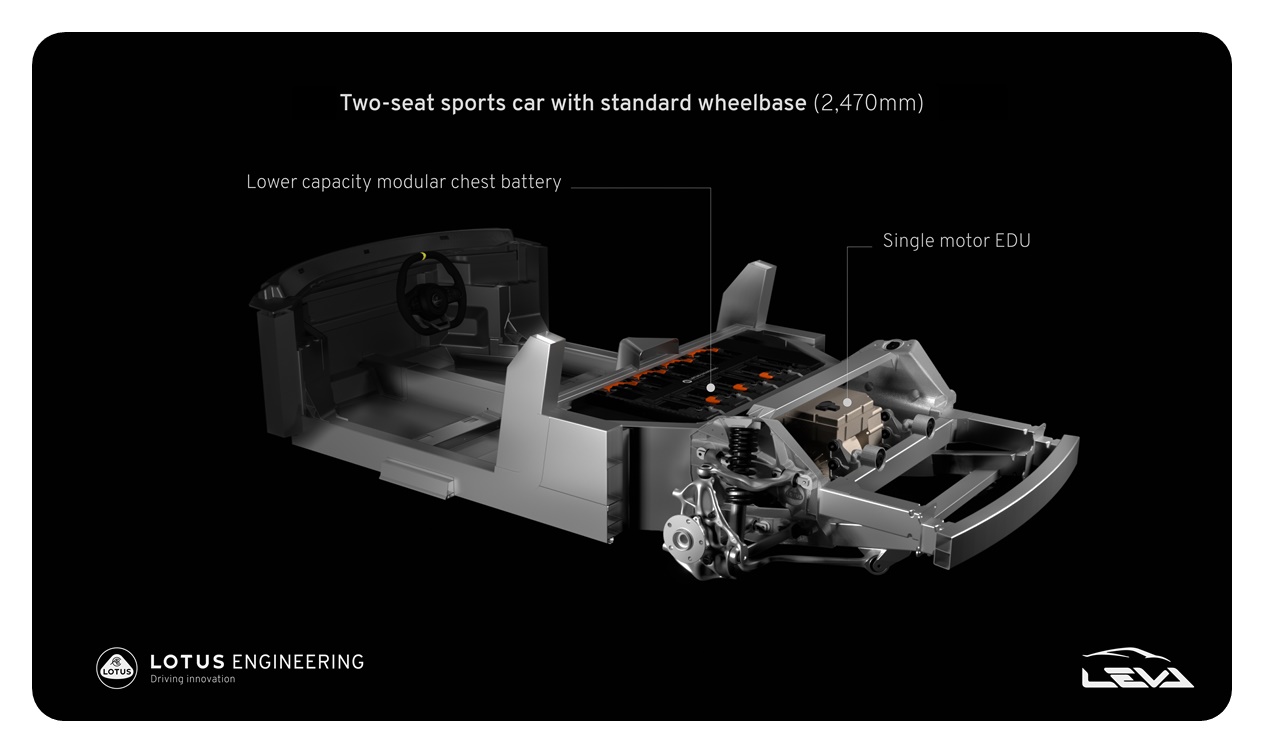

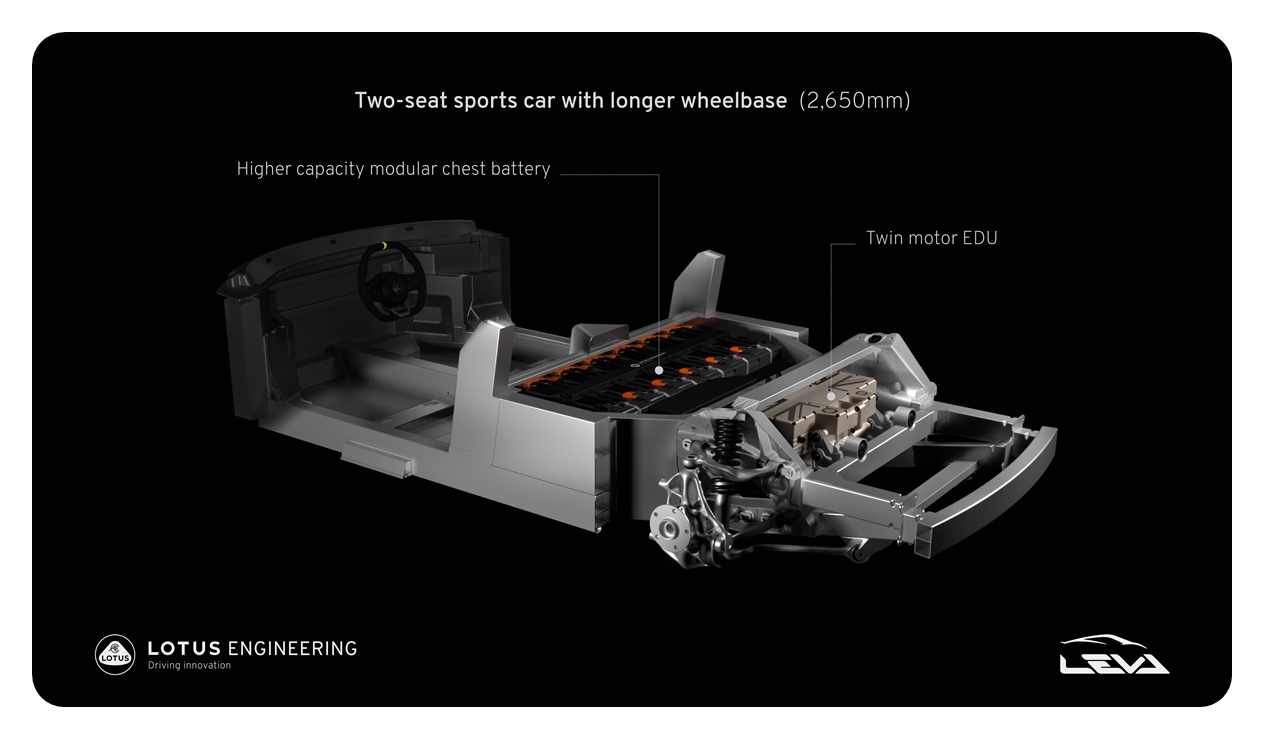

All three layouts feature a common lightweight die-cast rear subframe with multiple interchangeable components. This is the Project LEVA innovation: it means a single vehicle architecture can accommodate two different types of battery configurations.

The ‘Chest’ layout is where the modules are stacked vertically behind the two seats. A chest layout is a ‘mid-mounted power pack’, ideal for sportscar/hypercar vehicle types where a low overall ride height and low centre of gravity are required, eg Lotus Evija pure electric hypercar.

The ‘Slab’ layout, where the modules are integrated horizontally under the cabin, is most suitable for vehicles where a higher ride height and a taller overall profile is required. It is often referred to as a ‘skateboard power pack’ layout.

The innovative new subframe features cylindrical battery cells for high energy density, with the option of a single or twin electronic drive unit (EDU) to support. Cold cure, spot bonding and advanced weld processes mean reduced environmental impact during assembly.

This unique degree of flexibility and modularity in wheelbase and propulsion solutions will be the genesis for a wide variety of electric vehicle applications. These could be for the Lotus electric sportscar – scheduled for launch in 2026 – as well as for other clients through Lotus Engineering.

“Project LEVA is as revolutionary now as the Elise architecture was in 1996. In true Lotus spirit, significant weight-savings have been achieved throughout, with a focus on ultimate performance, efficiency and safety being engineered into the structure from the outset,” said Richard Rackham, Head of Vehicle Concepts at Lotus. He leads Project LEVA and is best known for his revolutionary work on development of the extruded aluminium Lotus Elise architecture 25 years ago.

Lotus Vision80 plan to transform company on journey of global expansion