At one time, when mention was made of ‘EV’ or electric vehicle, a small bubble shaped car might come to mind. And though electric motors do have a lot of zip, EVs were thought to be poor performers which provided basic transportation but no driving pleasure. But as we are now seeing, the EVs set to replace cars with combustion engines in coming years will continue to offer the driving pleasure that motorists enjoy, and even exhilarating performance – with zero emissions to damage the atmosphere.

And with new freedom for design due to the entirely different architecture, the stylists can come up with new forms that are sleeker than today’s cars. The Mercedes-Benz Vision EQXX concept shows us the sort of car we could be driving on roadtrips in future. It’s a concept car for now, though it is not just for show as many technological elements will likely be used in production models when they are validated and can be produced at a reasonable cost.

Range and efficiency are the key points about the VISION EQXX, achieved by having an ultra-efficient fully electric drivetrain and lightweight engineering. “The Mercedes-Benz VISION EQXX is how we imagine the future of electric cars. Just one-and-a-half years ago, we started this project leading to the most efficient Mercedes-Benz ever built. The VISION EQXX is an advanced car in so many dimensions – and it even looks stunning and futuristic. With that, it underlines where our entire company is headed: We will build the world’s most desirable electric cars,” declared Ola Kallenius, Chairman of the Board of Management of Daimler AG and Mercedes-Benz AG.

The result is an efficiency masterpiece that, based on internal digital simulations in real-life traffic conditions, will be capable of exceeding 1,000 kilometres with a fully charged battery pack. That’s a distance equivalent to going from Berlin to Paris, or from Beijing to Nanjing. Based on average distances driven per year, a driver in the USA or China would have to fully recharge the VISION EQXX only twice per month or, in Europe, just once per month.

The secret here is efficiency as the VISION EQXX uses less than 10 kWh of electrical energy to travel 100 kms. That equates to traveling 9.7 kms on 1 kWh of electrical energy. Translated into fossil-fuel consumption, this is around the golden figure of 1 litre per 100 kms/100 kms per litre or for those who remember the old measure, 282 mpg.

And it’s not about having a bigger battery either; in fact, the prototype battery pack in the concept car could easily fit into a smaller sized vehicle than the VISION EQXX. Battery technology is continuously advancing and what is used has the latest advanced developed by the German carmaker. Rather than simply increasing the size of the battery, Mercedes-Benz and the HPP team developed a completely new battery pack, achieving a remarkable energy density of close to 400 Wh/l. Overall, the battery weighs around 495 kgs.

“In effect, we fitted the energy of the EQS into the vehicle dimensions of a compact car,” said Adam Allsopp, Advanced Technology Director from HPP. “The battery has almost the same amount of energy but is half the size and 30% lighter. The battery management system and power electronics have been designed with an absolute focus on reducing losses. In achieving this efficiency milestone, we learnt a lot that will flow into future development programmes.”

Tasked with pushing the envelope of technical feasibility on all levels, the battery development team also decided to experiment with an unusually high voltage. Increasing the voltage to more than 900 volts proved an extremely useful research tool for the development of the power electronics. The team was able to gather a great deal of valuable data and is currently assessing the potential benefits and implications for future production models.

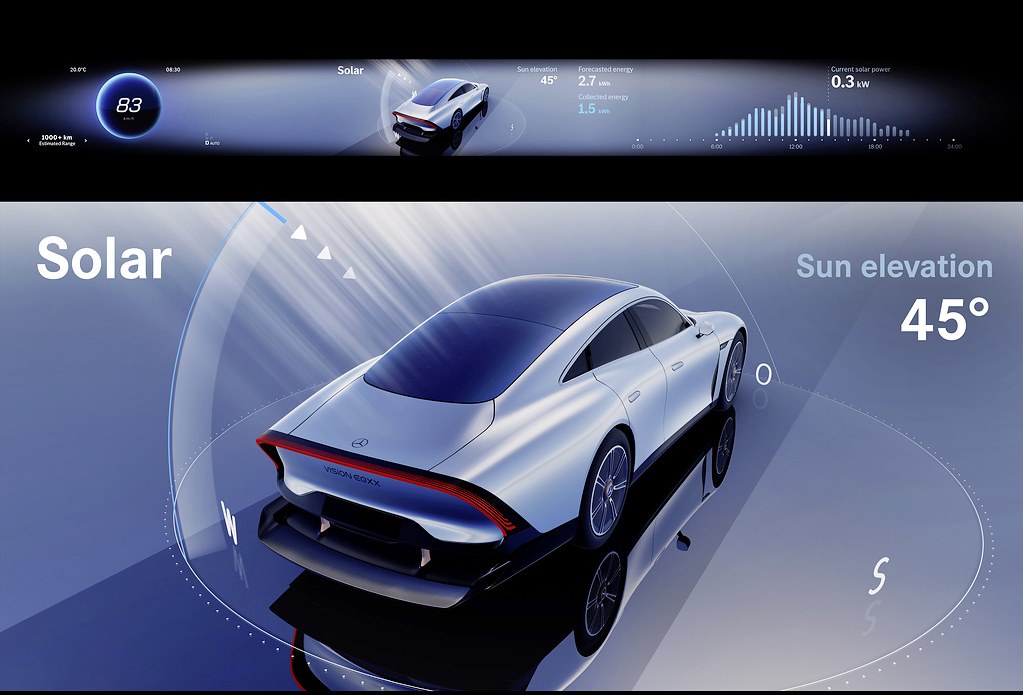

Additional energy is also draw from the sun, the original source of all energy on Earth. The electric system that powers many of the ancillaries gets additional energy from 117 solar cells on the roof. The net result of reducing the energy drain on the high-voltage system is an increase in range. On a single day and under ideal conditions, this can add up to 25 kms of range on long-distance journeys. The solar energy is stored in a lightweight lithium-iron-phosphate battery, which supplies a climate blower, the lights, the infotainment system and other ancillaries.

At its heart, efficiency means achieving more from less. The most familiar expression of automotive efficiency is that of fuel consumption or fuel economy. This is expressed in different ways depending on where we are in the world (eg litres per 100 kms, miles per gallon or kilometres per litre). Regardless of convention, they all relate units of fuel (energy) with units of distance. Electric mobility is no different in that respect, but the imperatives of electric mobility and sustainability have shifted the framework for efficiency.

For Mercedes-Benz, quantifying technological development across the board now goes beyond fuel efficiency alone. As well as meaning more range from less energy, it also means more tangible luxury and convenience with less impact on nature, and more electric mobility with less waste.

“Electric range sounds easy but is a complex technical challenge. The easiest way is to put a bigger battery in the car. However, this leads to diminishing returns due to size and weight. This is definitely not the smartest route and it’s also not the best use of scarce resources. With the VISION EQXX, we’re presenting the results of an extraordinary challenge: we pushed efficiency to a totally new level. And we explored new ways to increase the range of an electric car,” said Joerg Bartels, Vice-President for Vehicle Engineering and Overall Vehicle Functions.

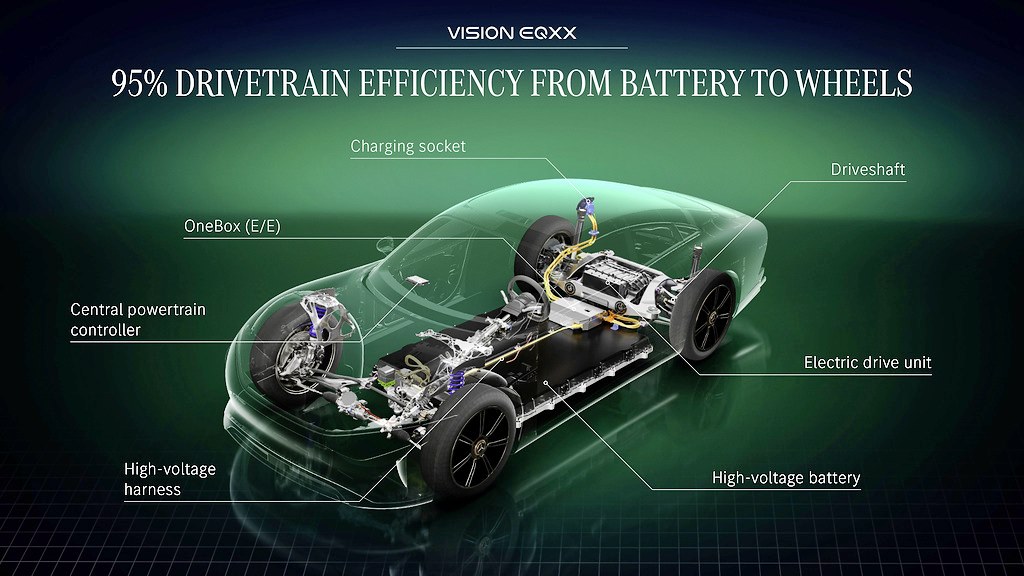

The electric drive unit is a dedicated unit consisting of the electric motor, transmission and power electronics featuring a new generation of silicon carbides. The power electronics unit is based on the one in the upcoming Mercedes-AMG Project ONE hypercar.

With output of around 150 kW, the super-efficient electric drivetrain (encompassing everything from battery to electric drive unit to wheels) provides the power and stamina. It is an electric drivetrain with 95% efficiency – that means up to 95% of the energy from the battery ends up at the wheels –compared to just 30% from even the most efficient combustion engine drivetrain or around 50% from an average (human) long-distance runner.

“One of the best ways to improve efficiency is to reduce losses,” explained Eva Greiner, chief engineer of the electric drive system at Mercedes-Benz. “We worked on every part of the system to reduce energy consumption and losses through system design, material selection, lubrication and heat management. And our fantastic simulation tools helped us find out quickly what works and what doesn’t.”

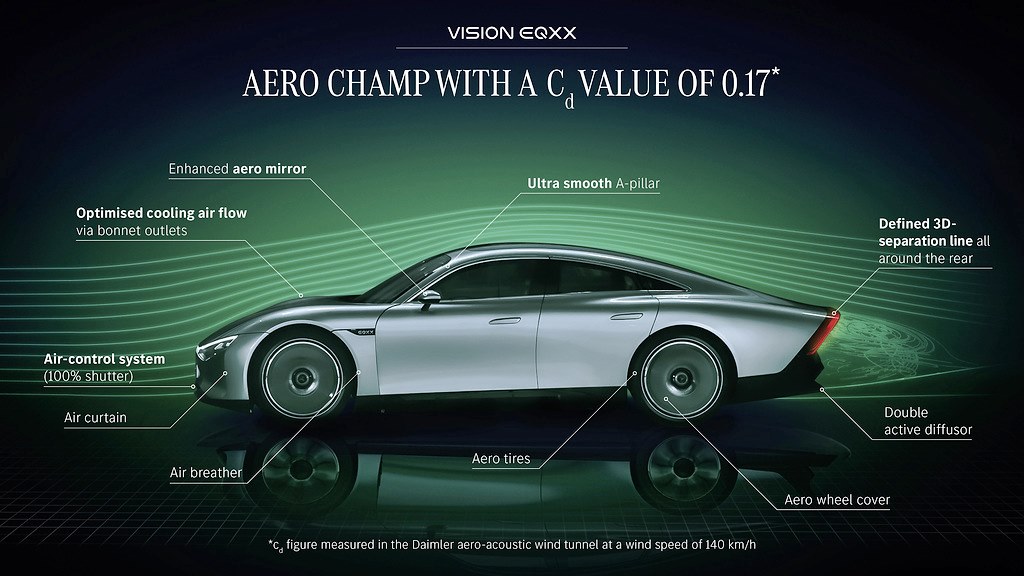

Aerodynamics have long been known to have a great influence on efficiency. Reducing the wind resistance of the car’s shape to as low as possible means the powertrain has to work less hard to achieve a given speed, reducing consumption or fuel or electricity. In the case of an EV, on a regular long-distance drive, almost two-thirds of its battery capacity may be used to ‘cut’ through the air ahead.

Through simulations and wind tunnel studies, the VISION EQXX has an ultra-sleek and slippery drag coefficient of 0.17 Cd. A huge amount of work went into integrating the painstaking passive and active aerodynamic features into the external form which retains the sensual purity of the Mercedes-Benz design language and the practicalities of a road car.

When it comes to lightweight engineering, the best on Earth is Mother Nature. No-one else comes close. Over millions of years, she has honed the finest examples of high-efficiency long-distance travellers – from the Monarch butterfly to the Arctic Tern.

With a considerably shorter timescale for the VISION EQXX, Mercedes-Benz engineers drew inspiration from her creations and pulled in some lateral-thinking external expertise to assist. The result is a weight-efficient design derived from engineering excellence paired with a sustainable combination of trash and Hollywood.

This intelligent use of sustainable advanced materials and methods inspired by nature is dubbed ‘bionic engineering’ and was facilitated by a digital process called bionic mesh design. Mercedes-Benz has a long history of applying bionic engineering techniques dating back to its “bionic car” concept study from 2005.

The VISION EQXX demonstrates that this is all within reach in a real-world vehicle that pushes the envelope on all fronts. It gives a clear insight into what premium efficiency for the electric and digital era looks like and feels like.