Ever since the pneumatic tyre was invented by J.B. Dunlop in 1887 (although Robert Thomson had actually patented the concept in 1845), punctures leading to air leaking out have been the one thing that motorists have had to live with. While there are solid tyres as well, these are hard and uncomfortable and don’t grip well.

Thus the pneumatic tyre filled with air has been used for decades and various approaches have been taken to overcome the problem of punctures. Run-flat tyres are one of them, allowing the car to continue being driven for some distance instead of changing the wheel with the spare. In some cars, the spare tyre is not provided to save weight and space, and a repair kit is provided instead.

Researchers at tyre companies have also been working on ‘airless’ tyres – not solid tyres but having a radical new construction that can offer the comfort and grip of pneumatic tyres but has no air to leak when punctured. Over the past 15 years, a few tyremakers have been developing such tyres, with Michelin and Toyo Tires having reached a stage where commercialisation is possible very soon.

Toyo Tires has been working on airless tires since 2006 and in September 2017, the company was the first in the industry to present a non-pneumatic tyre that could be used on passenger cars and driven at high speeds. The tyre was known, quite appropriately, as ‘no air’.

Tyres for EVs and autonomous vehicles

Toyo Tires’ development of noair is to prepare for the coming era of electric vehicles (EVs) and autonomous motoring. When EVs become widespread, many owners will not visit petrol stations as frequently as they do now to buy fuel. Therefore, the long practice of checking and inflating tyres correctly may no longer apply. Thus a tyre which does not need such checks would be useful.

Using proprietary technology, the noair tyre is said to have lower rolling resistance compared to conventional tyres. Adoption of tread rubber developed through Nano Balance Technology also promotes fuel efficiency while improving braking performance on wet roads.

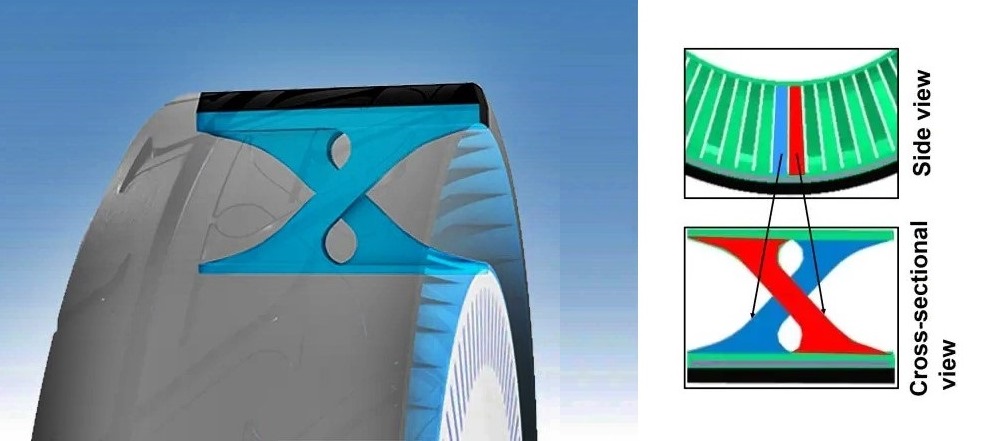

X-shaped spoke configuration

In order to have a tyre that can support itself without air, Toyo Tires engineers developed an X-shaped spoke configuration. These spokes, made of a special resin, are alternately crossed over the width of the tyre from inside to the outside and vice-versa to create the X-shaped configuration. An additional benefit of this configuration is durability.

Additionally, the number of spokes has been increased to 100 pitches which reduces the load on each spoke and achieves a quieter ride. The external diameter resin ring is reinforced with carbonfibre reinforced plastic (CFRP) which serves to reduce the load imposed on the spokes.

Now in 6th generation of development

The noair tyre has now reached its sixth generation of development where the spokes are now 10 times more durable than at the beginning. Durability has also increased by 40% and Toyo Tires states that the performance is now as good as conventional tyres. However, like other new technologies, the cost to make a noair tyre is still high and the company is working on bringing this cost down.

Meanwhile Michelin says that it will be able to offer its airless tyre called UPTIS (for Unique Puncture-proof Tyre System) by 2024. It is likely that the first car to run on airless tyres will be GM, which the tyremaker is now running a real-world testing program with. The data collected by engineers during testing will enable them to perfect the prototype in preparation for its market launch.

Run-flat tyres – an example of technology transfer from motorsports