The 760 is remembered as the model that saved Volvo and allowed it to exist up till today. Though the company had line of smaller models (the 300 series) from its Dutch subsidiary, it still needed a large volume-seller to take over from the aging 240/260 that had done well before the world got hit by the first of the oil crises.

When the first plans for the 760 were formulated in the mid-1970s, the automotive industry in general was experiencing a lot of difficulties. The first oil crisis had just passed and increasing concerns about air pollution caused by exhaust fumes had brought on stricter emission-control regulations, requiring new engineering solutions at extra cost. It was also a very difficult time as production costs increased and currency issues also made exports more expensive.

The 760 had taken a longer time to develop because it was a crucial model and not just a successor to the 200-series. It was to take Volvo further into the premium segment for the first time and had to be able to attract customers who usually considered the BMW 5-Series or the Mercedes-Benz E-Class (W123 at that time).

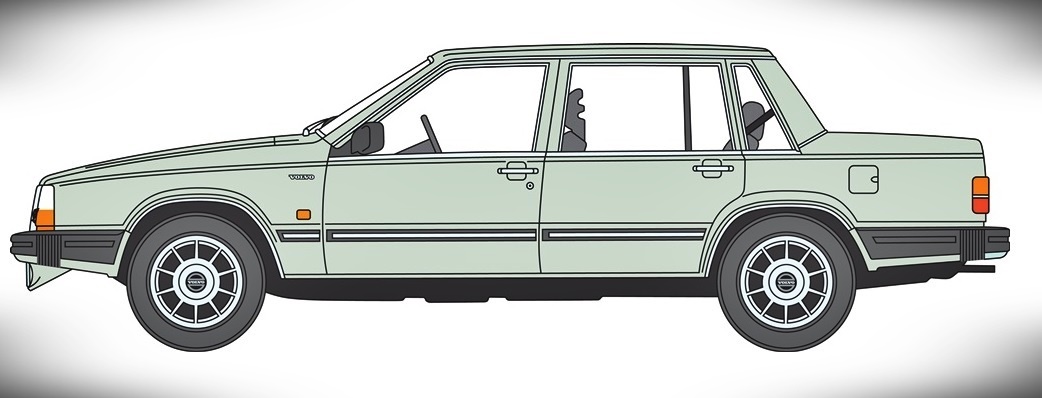

The car that was launched in 1982 was entirely new with a design that epitomised the Swedish obsession with ‘function having priority over form’ and it was taken to an extreme. Elegant in some ways, it was also slab-sided – at a time when car designs were ‘softening’ with rounded edges and more curves.

Some thought the looks were rather ‘American’ and that Volvo’s designers wanted to appeal to that market where the company sold the most cars but that was never admitted. Jan Wilsgaard, then Volvo’s head of design, said the car looked the way it did because ‘of function and space optimization’.

Apparently, the finance department wanted a design with straight and flat surfaces, as well as angular lines, preferably 90 degrees, in order to reduce the production costs as much as possible. This led to Volvo’s looking rather boxy for a long time and it would only be in the mid-1990s, with the C70 Coupe that Peter Horbury, who was the design chief, could declare that Volvo had finally gotten rid of ‘the box’.

Wilsgaard’s proposal somehow satisfied the different groups within the company: the rear end was somewhat like a stationwagon with straight body sides and with an abruptly cut-off boot. This led to having almost vertical rear screen and boxy rear section. Designers were in pursuit of ever-lower drag coefficients by making shapes sleeker and it was pointed out that the 700’s Cd of 0.29 was as good as the Porsche 928’s and 10% better than the 264.

The 760 was conceived in a time when conditions changed almost daily and in the company, there were many strong and different opinions regarding the new car. There was no Internet to surf in order to understand consumer thinking but Volvo designers made use of the best possible tool available at the time, a very thorough analysis of the surrounding world.

Very valuable during this process was the use of product clinics which Volvo used for the first time and at which people’s reactions regarding the new car were studied without revealing any details like the brand of car or its origins.

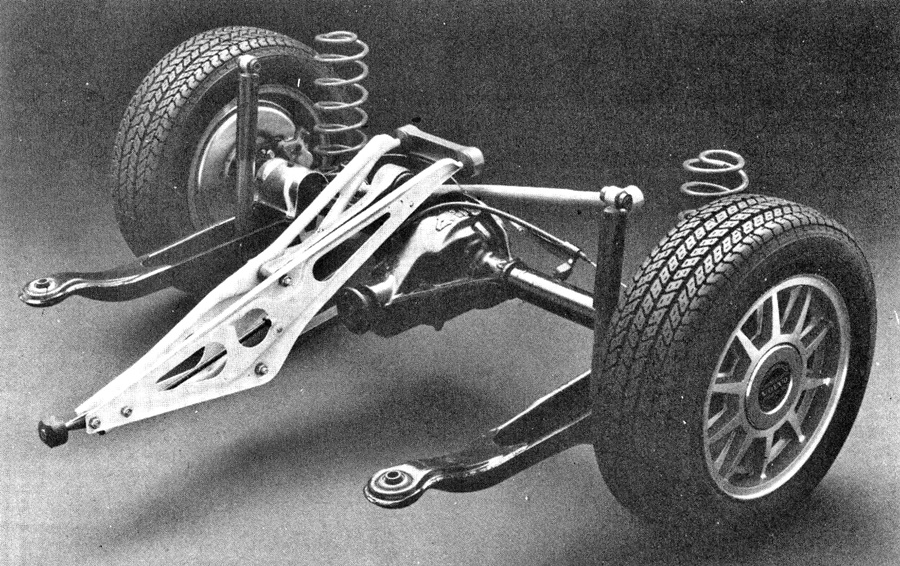

Besides safety, it was decided that reliability, fuel efficiency, longevity, serviceability, low noise levels, design and performance – in that order – should guide the development work on the new project which was given the code ‘P31’. It was also decided that rear-wheel drive should be employed, and that the wheelbase should be 10 cm longer than that of the 264 which was Volvo’s flagship then.

The car was also to be somewhat shorter than its predecessor but had to be the same width. Volvos were still being viewed as ‘tanks’ because of their bulk and weight but Volvo was never discouraged by that label though the engineers were told that the 760 should be at least 100 kgs lighter than the 264.

What people saw of the exterior was entirely new but Volvo didn’t have the financial resources to develop a brand new platform for the car. So the powertrain and chassis were carried over from the 264, the primary engine being the 2.8-litre ‘Douvrin’ V6 engine which was jointly developed by Volvo, Peugeot and Renault and built at one plant for all of them.

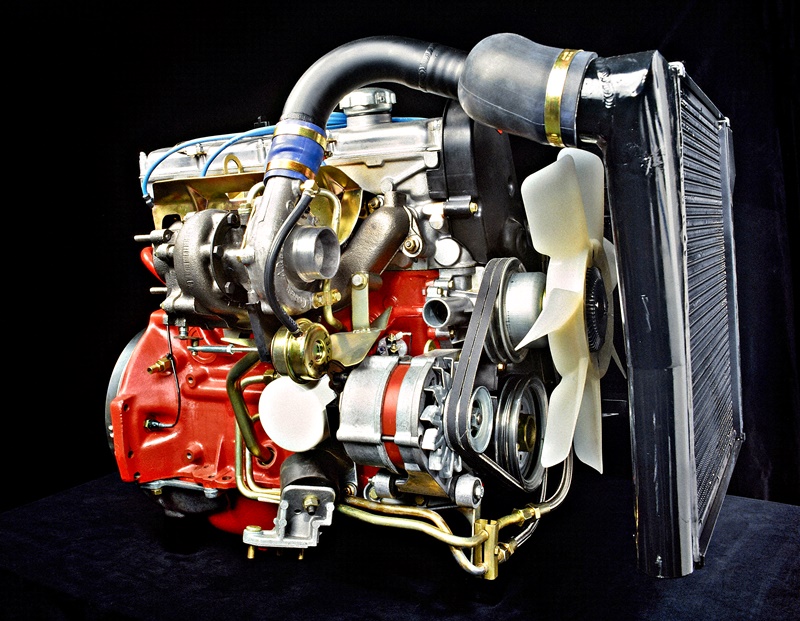

There was also a 6-cylinder turbodiesel unit supplied by Volkswagen and tuned to Volvo’s specifications. It was the quickest diesel car at that time. Later on, Volvo would also offer the 760 Turbo which had unusually quick performance – 8.5 seconds from 0 to 100 km/h – which was very quick for a Volvo in those days.

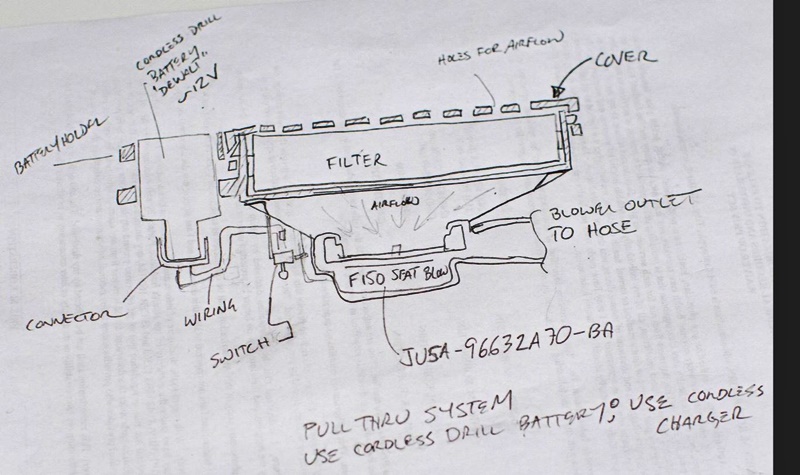

Volvo also examined the idea of shutting down cylinders selectively when a high power output was not necessary. This was a fuel-saving strategy but it was very crude in operation and it was only some 2 decades later than Honda would be able to get the concept refined enough for use (GM did introduce such an engine in some of its models but it failed to catch on).

The 760 became a turning point for Volvo, product-wise and financially, and formed the basis for the continuation of the company. Like the later Galaxy project which saw Volvo moving into front-wheel drive cars with the 850, the P31 project was a massive industrial undertaking.

Longevity was also evident in the platform which continued to evolve up till 1998 when the last model with its roots in 760 technologies ended production. Records show that 221,309 units of the 760 were made (1,230,704 if the smaller-engined 740 is included) before it was replaced in late 1992 by the 960.

Volvo Cars and Geely to merge engine operations to create stand-alone business