23 years ago, Lexus introduced a new model which created a premium SUV class. It was known as the RX and in Japan, the same model was also sold as a Harrier under the Toyota brand (probably because Lexus was not sold in Japan yet). For the generations that followed, the Lexus and Toyota models were essentially similar until 2013 when they separated and the Harrier became an independent development.

The Harrier name and product had built up a strong reputation, even outside Japan and was a very popular parallel import in many countries, including Malaysia. Initially a JDM (Japan Domestic Market) model, its popularity eventually led to UMW Toyota Motor deciding to officially sell it in Malaysia from 2017.

Now comes a new Harrier, to be launched in Japan in June 2020, which is said to ‘go beyond the SUV category to offer new value as ‘a life-enriching partner’. Like its predecessors, it offers the same high quality in design and engineering.

The new Harrier has a front view that emphasizes sharp styling with fluid proportions through the continuity of lines flowing from the front upper grill through to the headlamps. The headlamps (with double-L DRLs) indicate individuality and technical advancement while enabling easy identification from a distance.

The narrowed coupe cabin has sportscar-like wheel housings extending from both sides of the body. Light from a thin, sharp line of tail lamps and stop lamps gives it an overwhelming sense of presence.

TNGA platform

The new Harrier uses the TNGA (GA-K) platform for its basic structure. This creates a highly rigid body with a low centre of gravity, enhancing both ride comfort and driving performance with a focus on driver sensitivity.

The suspension system uses MacPherson struts at the front and a double wishbone set-up at the rear. The front and rear suspension geometry has also been optimized to produce a well-balanced rigid body. Through thorough tuning and testing, Toyota engineers aimed to provide a ride that is both solid and graceful.

To improve steering convergence in the new Harrier, the shock absorbers have a smooth pedal stroke even in very low speed ranges are used. This enables the driver to feel the tyres gripping the road, achieving a high level of sensitivity.

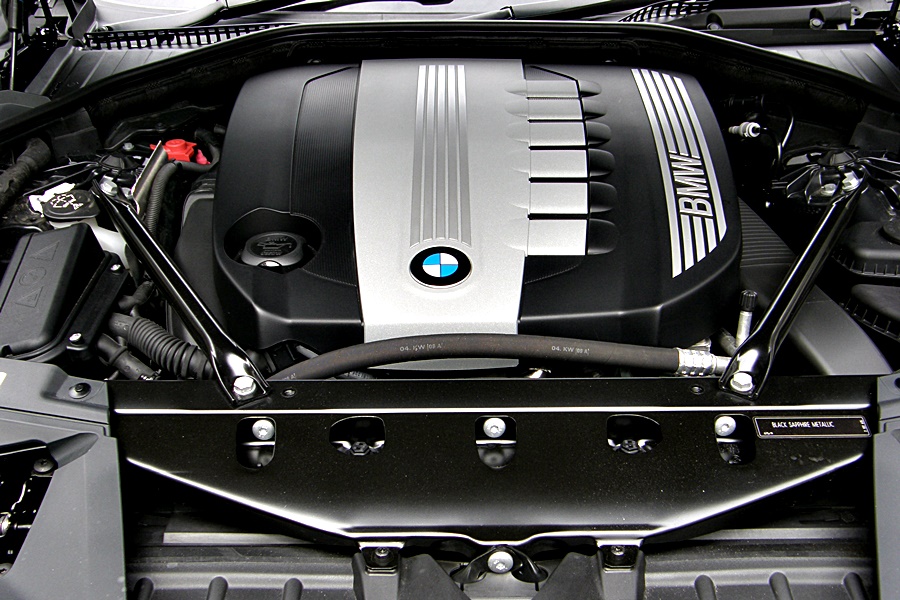

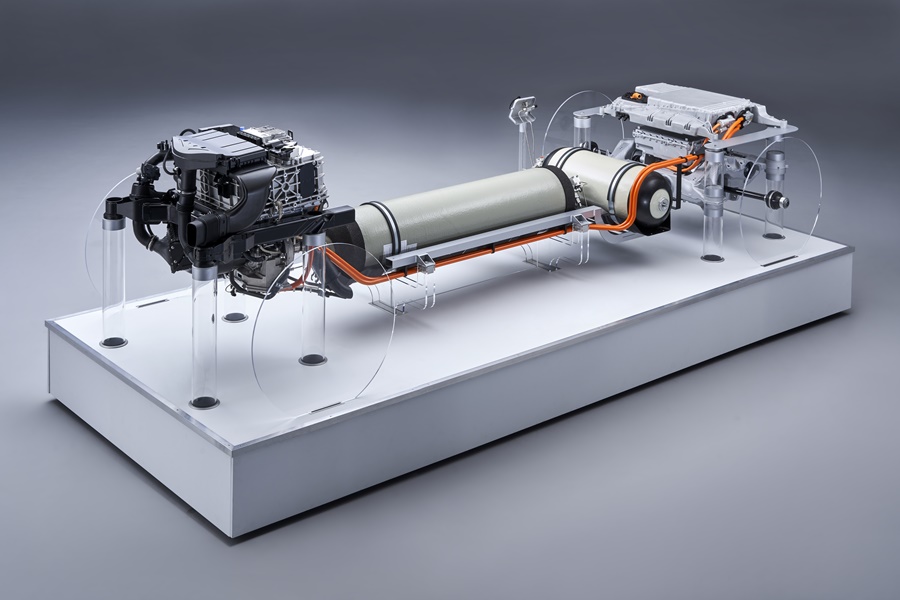

The TNGA platform brings with it the latest all-new Dynamic Force Engines (2.5 litres and 2.0 litres) and Direct Shift-CVT. Customers can also choose the continually evolving Toyota Hybrid System (THS II), which expands the options available more than ever. Drivetrains are AWD or 2WD as well as E-Four with the Harrier Hybrid.

Toyota Safety Sense

The new Harrier comes with Toyota Safety Sense (TSS), which employs a pre-collision safety system that detects pedestrians during the day and at night, as well as cyclists during the day. TSS includes Intelligent Clearance Sonar with Parking Support Brakes (Stationary Objects) that helps reduce and/or mitigate damage from collisions during low-speed driving in parking lots, etc.

There is also a Digital Inner Mirror, used for the first time by Toyota, which enables recording of images to the front and rear of the vehicle while driving. The hybrid variant features a 100-volt (AC)/1,500-watt accessory power outlet. This not only allows the use of electrical products using the same electrical outlets found in the home, but also enables the SUV to be used as a power generator during blackouts and other times of emergency.

Ruggedness and individuality

The interior employs tactile synthetic leather to create the image of a natural-looking silhouette wrapped in thick leather, and bentwood-inspired wood tones and piping throughout, presenting a casual air of quality.

A panorama roof, used for the first time by Toyota, is equipped with electric shades and electro-chromatic windows. When the windows are dimmed, soft light penetrates the cabin. Low-contrast browns, greys, and blacks are used to create a calming atmosphere that is both chic and mature.

The centre console presents a wide and imposing impression of a horse’s saddle. It combines with an instrument panel set within the edges of the ‘saddle’ to present a generous ruggedness with an emphasis on individuality.

Toyota’s new painting process with highest coating efficiency in the world