With the new 620R, McLaren now offers a car with ‘true motorsport credentials’ in a fully road-legal package. An evolution of the competition specification of the 570S GT4, only 350 units of the limited-edition coupe will be available worldwide. In the UK, the car will be priced from £250,000 (equivalent to RM1.37 million) and production will start next month.

“The McLaren 570S GT4 is a first-class GT race car, having won races in every championship it has competed in since its first appearance in 2017 and it is attracting an increasing number of customer racing teams. Now, in response to repeated customer requests, we have homologated that class-leading package for the road in the new McLaren 620R, a limited-edition, 620PS superlight coupe that is the perfect choice for an enthusiast wanting an authentic motorsport driving sensation – and performance to match – on both track and road,” said Mike Flewitt, CEO of McLaren Automotive.

Seamless transition from race track to road

As the ultimate track-focused, track-ready but roadgoing McLaren Sports Series model, the 620R is destined to be both rare and collectable, thanks to its strictly limited production run. It is a unique proposition, delivering a pure motorsport experience in a road car with authenticity. It looks like a race car, handles like a race car, performs like a race car and feels like a race car.

The overall result is a seamless transition from race track to road – and vice versa. Exclusive and extreme in equal measure, the 620R retains the DNA of a fully homologated track car yet is free from the restrictions that race regulations apply.

A high level of commonality with a 570S GT4 has been integral to the development of the 620R from the very outset. They have the same, single-piece carbonfibre Monocell II chassis providing the foundations for the strength and light weight of the car, with a targeted lightest dry weight of 1,282 kgs. This carbonfibre core – a McLaren signature that in different guises features in every car in the company’s range – also underpins the dynamic precision and composure for which McLarens are renowned.

These characteristics have been enhanced in the 620R by the inclusion of the GT4’s adjustable aerodynamic elements, race-derived suspension components and powertrain recalibration to increase power and performance.

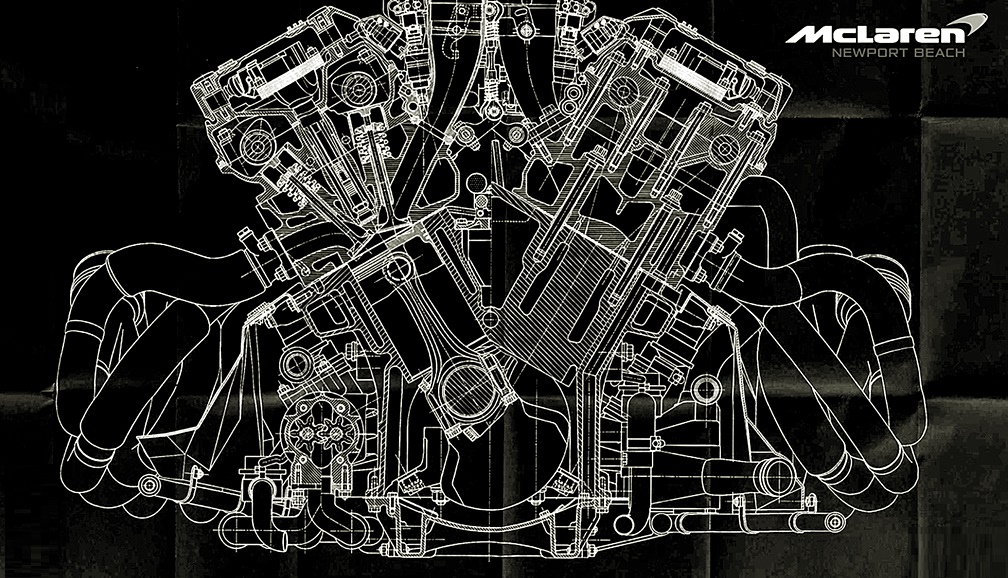

Same powerplant as GT4

The 620R has the same M838TE 3.8-litre twin-turbocharged V8 engine used in the GT4 but with a significant difference in power output. Not constrained by stringent racing regulations has allowed the engine ECU and turbocharger management to be reconfigured to generate 620 ps, making this the most powerful Sports Series car yet.

The engine also develops maximum torque of 620 Nm and even with lap times more important than sheer top speed, the combined outputs helps to deliver benchmark performance figures of 0 – 100 km/h claimed to be 2.9 seconds and 0 – 200 km/h in 8.1 seconds. Maximum speed is said to be 322 km/h and we don’t doubt it being possible.

The 620R has the GT4’s two-way manually adjustable coil-over motorsport dampers which feature 32 clicks of adjustment per corner to allow a driver to tailor compression and rebound rates to suit their driving style and track conditions. The dampers also help to bring weight down overall, being more than 6 kgs lighter than the regular Sports Series units.

Stopping power comes from McLaren’s latest lightweight braking system which, in the track-focused set-up on the new 620R, comprises carbon ceramic discs and forged aluminium brake calipers all round, with improved pedal response, modularity and resistance to fade even after repeated hard-driven circuit laps.

Option to use slick tyres

The 620R runs with standard Pirelli P Zero Trofeo R semi-slick tyres, but drivers who swap to the optional, full-slick motorsport tyres when they arrive on circuit will experience a whole new level of braking. Specially developed for McLaren by Pirelli’s Motorsport team, the slick tyres are optimised to complement the motorsport brakes and race-derived suspension of the 620R. They unlock a contact patch 8% larger than that of the road tyre, increasing lateral G-forces and enabling quicker lap times.

This is the first time that a road-legal car with 19-inch front wheels and 20-inch rear wheels has been engineered to be able to run on slick tyres without the need for additional mechanical adjustment. This means that if weather conditions allow, owners can on arrival at a circuit either fit a second set of wheels or change tyres and go straight out on track without further delay.

While the rear wing quite literally stands out as an obvious distinguishing feature on the 620R, it is not the only component adapted from the GT4’s aggressive track specification to meet road homologation standards. The front bumper, splitter and bonnet have been redesigned – the splitter retaining pronounced aero blades and cut-out – while the carbonfibre bonnet has twin nostrils to aid downforce and clean up the airflow over the top of the car.

Track-inspired cabin

The interior clearly and immediately stands out as track-inspired – any GT4 race driver will feel instantly at home. As with any serious circuit car, it is as much about what has been stripped out as what has been included: the 620R does not have a floor carpet or a glovebox. Air-conditioning, IRIS Navigation and an audio system are also missing from the standard specification although all can be selected at no additional cost.

Driver and passenger are secured in super-lightweight carbonfibre racing seats by 6-point racing harnesses, fitted as standard. Key ‘track touchpoints’ include the red 12 o’clock mark on the steering wheel. Structural carbonfibre elements such as extended shift paddles, steering wheel spokes and centre console enhance the sense of being in the cabin of a race car.