Open-topped cars may not command big volumes but they are still very much in demand, at least in the upper levels of the market. So it is worthwhile engineering a convertible variant (and it’s not just a matter of leaving out the roof) as there will usually be more than enough buyers. That is likely to be the case with the new 765LT Spider, a complementary model to the 765LT ‘Longtail’ coupe that McLaren unveiled last year.

This new Spider is McLaren’s most powerful-ever convertible model and with only 765 cars to be available, it will be an exclusive McLaren with each unit having a pricetag starting from £310,500 in the UK (about RM1.823 million before Malaysian tax). MSO Clubsport Pack and MSO LT Black Pack options are available, plus other individual MSO options.

Carrying over the coupe’s dynamic and aerodynamic DNA with no structural compromise and only a minimal 49 kgs weight increase – primarily from the retractable hardtop and accompanying operating mechanism – the 765LT Spider weighs just 1,388 kgs,, which is 80 kgs lighter than a 720S Spider and around 100 kgs lighter than its closest comparable competitor.

High-performance lightweight materials feature throughout, with advanced carbonfibre technologies used for body components. Specific weight-saving components include titanium exhaust system (saving 40% over steel equivalent), Formula 1-grade transmission materials and thinner glass.

Up to 22 kgs has been saved in the development of the LT’s bespoke Ultra-Lightweight forged alloy wheels. These are fitted with Pirelli P Zero Trofeo R tyres specially developed for the 765LT. Titanium wheel bolts are also standard fit.

In addition to all this, a significant proportion of the 80-kg weight-saving over the 720S is achieved inside the cockpit. The carbonfibre-shelled racing seats fitted as standard are together 18 kgs lighter than the 720S sports seats.

The cockpit’s central tunnel is made of carbonfibre just 0.8 mm thick; the door pockets are replaced by nets; and carbonfibre has been used for such micro-details as the window switch surrounds, steering wheel clasp and Active Dynamics Panel surround. Further weight is saved by deleting the floor carpet (saving 2.4 kgs), air-conditioning system (1 0kgs) and audio system (1.5 kgs) – although the latter two can requested by customers at no extra charge.

The Spider version of the carbonfibre MonoCage II – designated MonoCage II-S – was developed alongside the coupe monocoque and shares most of its structural elements, including the windscreen surround. Such is the strength and stiffness of the structure that no additional bracing is required over the coupe – another weight-optimising factor. At the rear of the car, carbonfibre structural supports are fully bonded into the chassis to provide roll-over protection.

The electrically operated, one-piece carbonfibre Retractable Hard Top (RHT) goes from closed to open within 11 seconds (among the world’s quickest) and can operate at speeds of up to 50 km/h. The convertible roof design plays an integral role in the structure, featuring a carbonfibre frame within the RHT panel and creating a full carbonfibre shell when closed.

The roof mechanism, powered by 8 motors, is also among the world’s quietest. Occupants will experience a sound no louder than 50 dBA during operation, with a peak of 60 dBA during the latching process – twice as quiet as the roof of the 675LT Spider, the first convertible LT supercar.

The rear window, which can be lowered even when the roof is up to intensify the quadrophonic exhaust note, has its own motor, as does the RHT latching mechanism. All these motors are optimised to work in parallel, allowing the roof to begin to move before the tonneau has completely opened, which saves time

There are also additional comfort benefits for occupants: because it is a single-piece panel with no central seal, headroom is improved, while the extended length of the roof panel allows the tops of the A-pillars to be further forward, enhancing the sense of space and easing ingress and egress.

Like every LT, the new Spider is designed to excel on track; the ability to remove the roof makes it an even more immersive and compelling car to drive on the road. There is the same highly evolved aerodynamic package as the coupe but the active rear wing calibration is revised to reflect whether the roof is up or down. A recalibration of the dampers has also been necessary to account for the minor increase in weight. As a result, the Spider matches the coupe’s aero performance in every respect, with class-leading downforce 25% greater than that of a 720S Spider.

765 ps from the 4-litre twin-turbocharged V8 engine makes this the brand’s most powerful convertible, and it has a best-in-class power-to-weight ratio of 598 ps-per-tonne at lightest dry weight – with 800 Nm of torque. The transmission gear ratios have been revised and makes in-gear acceleration 15% quicker than a 720S Spider.

720S with Gulf racing colours recreated by McLaren Special Operations

Until this century began, motorsports were viewed mostly at ground level, with spectators able to see cars zooming by on a rally stage or a closed circuit. Major events had aerial coverage which required using a helicopter which wasn’t cheap. In-car footage had been available earlier though but usually available only after the event.

Today, spectators and viewers around the world can watch an event from overhead as drones have made it easier and cheaper to capture imagery from above. Even ordinary drones can provide a view that is exciting and give a broader perspective.

As good as watching from a helicopter

One example of drones being used for motorsports is in the unique Extreme E series for all-electric off-road SUVs. The series has so far gone to the Saudi Arabian desert and the long beaches of Senegal, with the next venue to be Greenland. And at each of the first two rounds, viewers have been able to follow the vehicles as they raced over the rough terrain and able to watch exciting overtaking manoeuvres from overhead. It’s as good as having a helicopter of your own to watch!

The company that is covering the Extreme E rounds is Aerios Solutions which not only captures the footage but also broadcasts it live to a worldwide audience. The drones, which are ‘must-have’ for entertainment and audience wow factor, offer a degree of dynamic perspective that no helicopter or plane could possibly achieve. They are event environmentally friendly in that they don’t need fossil fuel to operate, unlike helicopters. Drones run on electricity and their batteries are recharged on-site using Extreme E’s hydrogen fuel cell generators.

Highly skilled drone pilots

Aerios Solutions, a leader in drone filming technology – has 3 champion stunt helicopter pilots on its team. “It’s safe to say we have a pretty experienced crew at Aerios Solutions!” said its Director Martin Taylor. “Two of our crew are actually world champion helicopter stunt pilots, and all of our pilots have extensive experience in the drone industry including working in major film productions.”

The skills of these pilots are required to control the drones that capture the ODYSSEY 21 SUVs in what is likened to ‘Star Wars meets Dakar Rally’ style racing. “As a race series, Extreme E represents so many world firsts. Live sports programming with this level of remote production has not been done in these parts of the world before. In Greenland, we’ll be in a valley with a glacier on the side; in Senegal, we were on a beach next to a lake; and in Saudi, we were literally in the middle of a vast desert canyons. Getting live pictures out of these places with the level of integration we’ve got, just hasn’t been done before,” Extreme E’s Chief Marketing Officer, Ali Russell, proudly explained.

Aerios Solutions came on board as it was well known to Extreme E’s film production company, Aurora Media, in the past. They were an ideal outfit to get the coverage and nobody else is doing anything close – in extreme environments, with augmented reality and really dynamic coverage.

Operating in remote locations

There is no doubt that it is insanely tricky flying and shooting in Extreme E’s remote locations. However, even before that starts, the logistics are among the main challenges. “Getting a whole live broadcast to such remote areas is a huge challenge. There is absolutely no infrastructure on site before Extreme E arrives there. Every piece of equipment has to be transported to the operating site. Thinking ahead and planning are essential to making the operation a success,” said Taylor.

“Transport around site is difficult, and we normally need 4-wheel drive vehicles just to get to the operating positions. The remote locations have given us some unique challenges, from the baking sun and steep canyons of Saudi Arabia, to even being chased by vultures in Senegal!” he revealed.

“In terms of equipment on-site, we have three main large drones for live broadcast, along with numerous small FPV (First Person View) drones. these are extremely small, extremely quick, lightweight and agile racing drones which we use for recording fast dynamic, close shots,” Taylor said.

The three actual broadcast drones, made by a company in the Netherlands, are highly modified versions of the Acecore Technologies Neo and Zoe drones. They are large, stable platforms able that carry not only the camera and gimbals, but also the complex broadcast equipment and they can fly in all weather conditions which is pretty important in this championship.

Working together from 3 countries

In total, there are 6 pilots on site, operating three drones simultaneously. There is an engineer on call in the UK, along with Taylor in the broadcast suite in London. To carry out live broadcasting to millions of screens around the world, the footage is transmitted from the drones to receivers on-site. From there, the signal is transmitted to the director and producer in the broadcast compound and then, via satellite, to the broadcast suite in London. Finally, the signal is transmitted to a technical team in the Netherlands. After all this, the signal travels back to the on-site broadcast team, before finally being transmitted worldwide via satellite.

Even if you consider yourself a fairly competent pilot of a DJI drone, the drones used by Aerios Solutions are extremely complicated to operate. A minimum of two pilots is needed to operate each drone – one pilot controls the drone itself, the other the camera/gimbal.

“The main skills required are a high level of piloting skill. The pilots need to be extremely skilled and experienced in actually flying the drone and, of course, technical skill meaning they need to be able to maintain the drones in the remote areas. Also, team working skills – the pilot and gimbal/camera operator work as a team to get the live broadcast shots. Normally, the gimbal/camera operator directs the pilot, but they work together ‘as one’,” said Taylor.

He added that communication skills are also important. Not just communicating with each other as they chase the vehicles around the course but also with the production team. They are directed from the on-site producer, the on-site director and the production team in London.

Click here for other Extreme E news and articles.

Earlier this year, coachbuilder Huber announced a Lamborghini Aventador facelift, and the first unit has been delivered to a customer in the United Kingdom. The customer is the membership Secretary of the Lamborghini Club UK, Ciro Ciampi who also founded the car community known as ‘Petrolheadonism’.

Ciampi received his latest toy on the lawn of the former residence of David and Victoria Beckham. The property is currently home to one of Britain’s most private car collections, creating a spectacular setting for the handover. The scene was not only complemented by the car collection but also by the attendance of Italian supercar patron, Fabio Lamborghini. He was impressed by the Era and happy to give his approval by being the first to unveil the car to the world.

Designing for the aftermarket

Led by Sean-Peter Huber, the UAE-based brand is on a mission to build a new community of collectors and car enthusiasts who value going back to the drawing board. His passion for car design has put them in uncharted territory in the aftermarket, but the first steps are already telling of what an exciting future the brand holds.

Entitled ‘Era’ to mark 10 years of the Aventador and to pay homage to the end of its production, Huber’s Era has created a new take on one of the worlds most revered supercars. The team focused on creating new body panels that respect the familiar DNA, exchanging the front and rear bumpers with an entirely new design in carbonfibre and an optional carbonfibre boot. Huber said: “The Era should remind us of how much we all admired the Aventador when it was launched in 2011”.

Limited to 21 sets

The fully-funded project is independent of Lamborghini with the first batch of bumper units already taken up by selected collectors who have been supporting Huber’s vision from the start. The Era price starts at 30,000 euros (about RM150,000) and will be limited to 21 pieces in the current edition.

According to Raj Singh, founder of Supercar Service Ltd (Huber’s UK distributor), in their 11-year history, they have not found an aftermarket design that integrates so well with the LP-700-4 chassis. As an option to customers around the world and to assure quality control, Huber has designated Supercar Service as ‘flying service’ partner, sending personnel to customer locations to assemble the Era.

Production of Lamborghini Aventador ends with LP 780-4 Ultimae

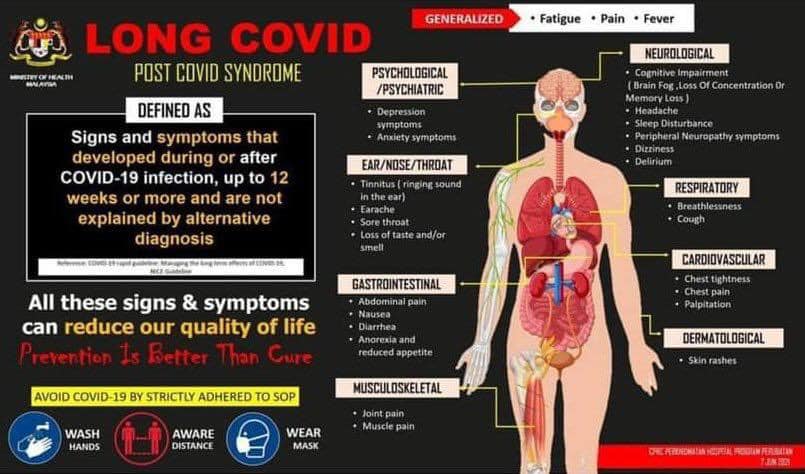

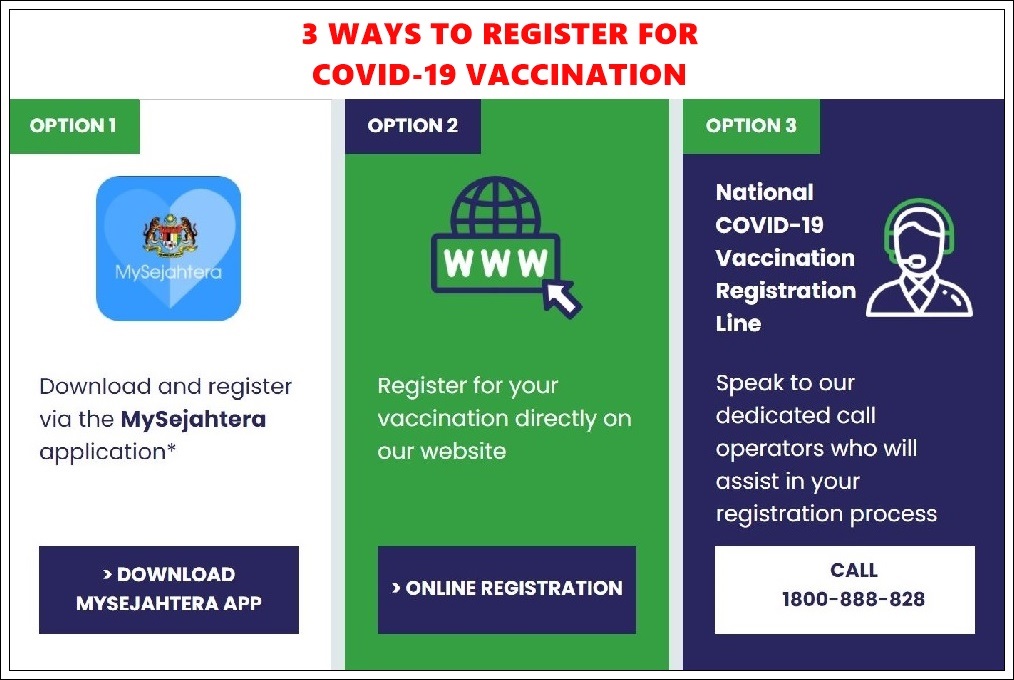

Getting as much of the population vaccinated to help reduce the severity of COVID-19 infection is a priority. The effort is being carried out by the government as well as the private sector, which is providing areas to set up vaccination centres. One such company is PLUS Malaysia Berhad which has established an Integrated Public Vaccination Centre (PPV).

The IPVC has been set up in partnership with its medical advisory partner, Primer Cherang, together with Protech Health, the implementer of private medical practitioner and healthcare NGO participation in the National COVID-19 Immunisation Programme (PICK). The IPVC is at the PLUS HQ situated near the Subang exit off the New Klang Valley Expressway (NKVE) in Selangor. The facility can inoculate up to 2,000 persons per day.

One of 14 public immunisation venues

The COVID-19 Immunization Task Force (CITF) has selected the PLUS HQ as one of the 14 public immunisation venues to accelerate the dispensing of vaccines through Operation Surge Capacity. This will ensure that all adults will receive at least one dose of the vaccine by August 1 and help flatten the infection curve.

“As of Sunday, July 25, PICK has reported that over 16 million doses comprising first and second doses have been administered, of which11.5 million of our population has received their first dose and over 5.4 million are fully vaccinated with two doses. Based on this data, PLUS is proud to be able to play its part in helping the country to ramp up its immunisation numbers. The sooner we are able to attain the target to allow us to enter Phase 4 of the National Recovery Plan, the sooner the economy can improve, and businesses can revive,” said Datuk Azman Ismail, Managing Director of PLUS.

“I urge you to regularly check your MySejahtera updates and who knows, you may be visiting our Persada PLUS HQ soon. In the meantime, continue to adhere to SOPS if you must be out and about; if not, it would be best to work from home where possible until you are fully inoculated. Hopefully by then, as the government has indicated, you may get to travel on our highways again,” he added.

The participation also provides the opportunity for the employees of PLUS to be part of something meaningful and historical. Warga PLUS will join as volunteers and assist the 150 health personnel from Primer Cherang and Protect Health.

PLUS customers now have PUTRI to help them with their enquiries

Although SsangYong Motor is still in a difficult financial situation, product development and business activities are still ongoing. Work on new models continues and one of the models that will be in showrooms will be a next-generation SUV presently designated ‘X200’. The Korean carmaker, owned by India’s Mahindra Group, has a newly created design vision and philosophy and this is being adopted for the new model.

New design philosophy

“The design of the new X200 is based on SsangYong’s new design philosophy ‘Powered by Toughness’, and follows on from our recently announced J100 mid-sized electric car. With this new design, the company is showcasing its new product identity to communicate a powerful and modern SUV while drawing on the inherited values its authentic heritage,” a spokesperson for the company said.

‘Powered by Toughness’ is a design philosophy that emphasises the importance that SsangYong places on the value of design. Along with the themes of strength and modernity, it underpins its long standing ‘Korean Can Do’ message which has been central to the Korando product line over 4 generations, dating back to the original from 1983.

The design philosophy is based on four formative concepts: Robust Architecture, Unexpected Delight, Vibrant Contrast, and Communion with Nature. “Of these four elements of sculptural identity, ‘Robust Architecture’ pursues the beauty of tough structural shape and detailed sculptural beauty. ‘Unexpected Delight’ appeals to differing lifestyles, offering amusement and excitement by embodying a design that values more than mere transportation. ‘Vibrant Contrast’ expresses the original characteristics of a tough SUV through the contrast between aesthetic elements of colour, texture and modelling, while ‘Communion with Nature’ is intended to harmonise with the natural world, echoing the sensibilities of our customers,” explained Lee Kang, Head of the SsangYong Design Centre.

Korando and Musso heritage

Besides being guided by the design philosophy, SsangYong’s future models, such as the J100 midsize electric model and new X200, will be designed with the heritage of the original Korando and Musso. These two SUV models are of significance in the company’s and Korean automobile industry’s history.

It is expected that the design philosophy will allow consolidation of its position as an authentic SUV brand. Forward-looking elements will include the use of eco-friendly powertrains, responding to the biggest trend in the automotive industry which is now taking place.

J100 well received

Public response to the first design reveal of the J100 (shown below) last month on social media channels is said to be extremely positive and strong. The designers are also encouraged by feedback on the J100 and derivative pick-up model on which has indicated considerable positive interests.

“We have re-interpreted our future design vision and product philosophy by drawing heavily on our unique heritage. With the forthcoming J100 and X200 models, we have drawn a line in the sand in terms of design, and everything from this point forward will follow this new brand design direction. It is a very exciting time for SsangYong and will build on the history and heritage of its unique and distinctively authentic SUV designs to impress its customers of the future,” Mr. Lee Kang promises.