BMW Group Malaysia has long been pro-active in providing assistance and support to local organisations which helps the underprivileged and marginalised communities. It has also initiated a subsidy programme to make travel in cars safer for small children by helping their parents acquire childseats.

Providing food relief

The latest initiative by its subsidiary, BMW Group Financial Services Malaysia, is to raise funds in support of the Refuge for the Refugees and Empire Project. Both are local organisations actively providing food relief in Malaysia during the COVID-19 pandemic. These initiatives are also supported by BMW Group Malaysia in terms of logistics and delivery needs by providing vehicles.

“In these challenging times, it is imperative that we come together to lend a helping hand wherever we can. Although we are looking at a gradual shift into the next phase of the National Recovery Plan, we want to continue providing support to these exceptional non-profit organisations who work hard to ensure that underprivileged families and individuals in the country do not go hungry,” said Danielle Maassen, Chief of Sales & Marketing of BMW Group Financial Services Malaysia.

RM100 contribution for each BMW/MINI funded

The initiative will see contributions of RM100, made on behalf of BMW and MINI customers, for every funded contract of the following models: the BMW 330e, 530e, 740Le xDrive, X5 xDrive45e, and the MINI Cooper SE as well as the SE Countryman. All funded contracts from September 1 to December 31, 2021 for the models listed are eligible for this initiative.

These contributions will support the Refuge for the Refugees food aid programme that serves upwards of 700 families in the B40, migrant and refugee communities on a weekly basis, as well as the various food and essential relief efforts conducted by Empire Project throughout the pandemic that serves marginalised Malaysians across the country.

Learn more about Refuge for the Refugees via rftr.super.site and www.instagram.com/refugefortherefugees/.

Learn about Empire Project’s latest activities at www.facebook.com/empireprojectwecareweshare/.

Just last month, Lotus confirmed it would be launching a new electric sportscar in 2026 – designated Type 135 – as part of a range of electrically-powered performance cars to be manufactured in the UK. The sportscar will have innovative new lightweight chassis technology developed through Project LEVA (Lightweight Electric Vehicle Architecture), which the carmaker mentioned last October.

Project LEVA is a research programme that’s accelerating the development of all-new lightweight structures for next-generation battery electric vehicles. The structure developed through Project LEVA will be integrated into the company’s new architecture for electric sportscars.

This structure represents the ‘blueprint’ for the next generation of electric sportscars, for future Lotus products, and for the Lotus Engineering consultancy to commercialise. One example of its innovation is that the rear structure is 37% lighter than it is on the Lotus Emira V6. It is fully adaptable to provide a platform for a range of vehicle types with variable layouts, wheelbase lengths, battery sizes and configurations.

All three layouts feature a common lightweight die-cast rear subframe with multiple interchangeable components. This is the Project LEVA innovation: it means a single vehicle architecture can accommodate two different types of battery configurations.

The ‘Chest’ layout is where the modules are stacked vertically behind the two seats. A chest layout is a ‘mid-mounted power pack’, ideal for sportscar/hypercar vehicle types where a low overall ride height and low centre of gravity are required, eg Lotus Evija pure electric hypercar.

The ‘Slab’ layout, where the modules are integrated horizontally under the cabin, is most suitable for vehicles where a higher ride height and a taller overall profile is required. It is often referred to as a ‘skateboard power pack’ layout.

The innovative new subframe features cylindrical battery cells for high energy density, with the option of a single or twin electronic drive unit (EDU) to support. Cold cure, spot bonding and advanced weld processes mean reduced environmental impact during assembly.

This unique degree of flexibility and modularity in wheelbase and propulsion solutions will be the genesis for a wide variety of electric vehicle applications. These could be for the Lotus electric sportscar – scheduled for launch in 2026 – as well as for other clients through Lotus Engineering.

“Project LEVA is as revolutionary now as the Elise architecture was in 1996. In true Lotus spirit, significant weight-savings have been achieved throughout, with a focus on ultimate performance, efficiency and safety being engineered into the structure from the outset,” said Richard Rackham, Head of Vehicle Concepts at Lotus. He leads Project LEVA and is best known for his revolutionary work on development of the extruded aluminium Lotus Elise architecture 25 years ago.

Lotus Vision80 plan to transform company on journey of global expansion

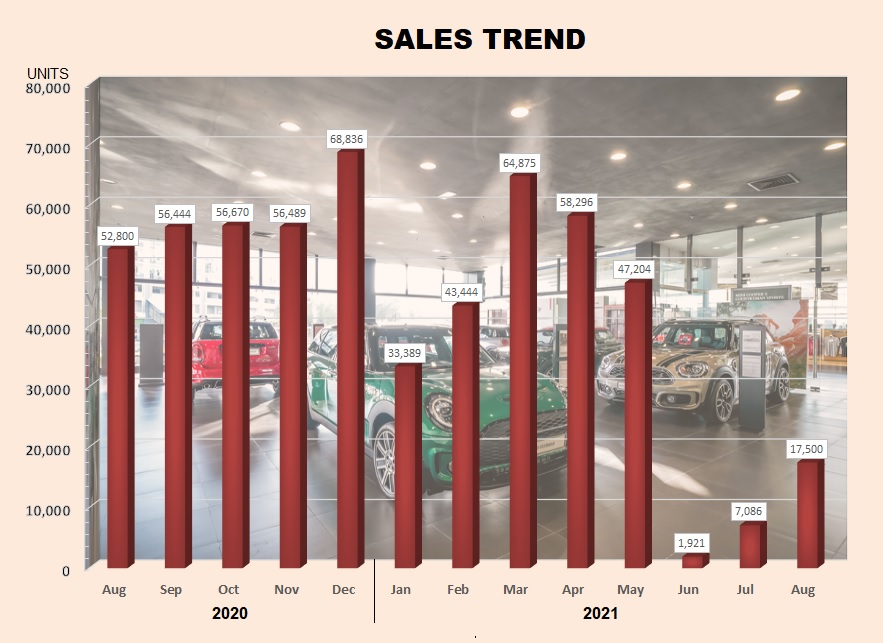

With business operations in most parts of Malaysia allowed to resume after over 2 months of forced closure, new vehicle sales and production started to rise in August. However, the Total Industry Volume (TIV) recorded was only 17,500 units as showrooms began operating only from the middle of the month. The August TIV was less than half of the average monthly sales during the first month of the year.

Compared to the same month in 2020, this year’s August TIV was 35,300 units lower although it was not as bad as in June when the full MCO lockdown began. In that month, the sales volume for the whole industry fell by 42,774 units,

As would be expected, the closure of showrooms has had an impact on the cumulative volume for the year. For the first 8 months of 2021, the TIV reached 273,757 units or 12,504 units (4%) less than for the same period in 2020. This has led the Malaysian Automotive Association (MAA) to reduce its TIV forecast for the year by 70,000 units to 500,000 units. This would be almost 30,000 units lower than the TIV for the whole of 2020.

The lockdown also saw production at factories having to suspend their operations. During the lockdown months, the auto industry used the PIKAS initiative to get its workforce vaccinated in preparation for resumption of operations.

From mid-August onwards, the government permitted factories to resume operations but the number of workers allowed would be dependent on the percentage vaccinated. Those with 80% or more of their workers vaccinated were allowed to operate at 100% capacity.

From January to August, the total output from all the vehicle plants was 258,024 passenger and commercial vehicles. The same period in 2020 recorded 263,876 units or 2% higher.

With four months remaining, the car companies are hoping for the market to pick up as much as possible. To achieve the MAA’s target of 500,000 units by the end of the year means that monthly sales will have to average 56,560 units. This may well be possible if you look at the sales during the last quarter of 2020. However, in 2021, many more people and businesses have been struggling with the prolonged restrictions of movements and spending on expensive items like new cars might not be considered or possible.

Perodua sales picking up but sales target for 2021 is lowered by 10.8%

Cars and shoes… in some ways, they can be considered have similar functions since both ‘transport’ people around, though in very different ways. Cars use energy from the combustion engine or electric motor to move but with shoes, you have to provide your own energy. So it’s not unusual that on World Car-Free Day (September 22), Volvo Cars Canada and Casca footwear will launch a limited-edition sneaker. Available in Canada for $198 (about RM645), the shoes have been inspired by the fully electric Volvo XC40 Recharge.

“At Volvo Cars, we are committed to setting the highest standards of sustainability in mobility and that goes beyond electrifying our fleet to transforming all aspects of our business. The shoe we have created with Casca in celebration of World Car-Free Day, is one way to recognize the many steps we are taking on our journey to climate neutrality,” said Matt Girgis, Managing Director of Volvo Car Canada Ltd.

For a carbon-neutral future

As would be expected, the shoe is all about sustainability in the long term, and both brands have a shared vision for a carbon-neutral future. On Volvo Cars’ part, there is a commitment to reducing lifecycle emissions per vehicle by 40% by 2025 and producing only fully electric vehicles by 2030. Casca’s adoption of water-based, low-energy UV treatment processes coupled with their 2-year product warranty are a testament to their ‘buy less, waste less’ philosophy.

“The Volvo XC40 Recharge was designed to reduce environmental impact, so it was the perfect inspiration for the shoe,” said Kevin Reid Lead Director and Co-Founder, Casca. “Through this collaboration, we’re also celebrating many design firsts – our first shared design, our fastest production to market, and new recycled materials we’ve never used before.”

Scandinavian influences

The goal was to create a shoe rooted in conscious design. Scandinavian influences of the XC40 Recharge were purposefully integrated for a collaborative new interpretation of Casca’s trademark clean lines. For instance, the ‘Thor’s hammer’ headlight influence can be seen in the linework and panelling, delivering a more performance-inspired aesthetic to Casca’s popular Avro silhouette.

The Swedish flag is represented on one shoe tag, while the classic Casca yellow can be seen on the other, honouring the collaboration between the two brands as well as minimalist, Scandinavian design.

Recycled materials

Of course, an important aspect of the shoe is how it is made and its environmentally-friendly credentials come from having 10% of each sole made from recycled car tyres, the first time this material has ever been used in a Casca shoe as part of an intentional repurposing and recycling of materials. Furthermore, 7 recycled plastic bottles are used to make the yarn for each breathable, flexible knit upper.

Those two features are a preview of some of the initiatives by both companies. By 2025, Volvo Cars aims to increase the share of recycled and bio-based materials in their vehicles by 25%. By 2022, all of Casca’s knit uppers will be made from recycled or renewable materials.

“We know that being advanced isn’t just about great design and technology; it means implementing ethical and sustainable practices,” said Braden Parker, CEO and Co-Founder, Casca. “This is just one of many similarities we see between our brand and Volvo Cars, we both want to create something with intention that lasts.”

Mazda x Mizuno driving shoes enhance Jinba Ittai for drivers

UMW Toyota Motor (UMWT) will be making a major announcement on Monday, September 27, 2021, which it says will be ‘inviting Malaysians on a journey that will give them the opportunity to experience a part of the future, today’. According to the company’s Deputy Chairman, Akio Takeyama, this development will have ‘a big impact on not only the brand but the industry as a whole, and the lifestyle as well as choices that we have become so accustomed to’.

Details of the announcement are not revealed but Mr. Takeyama associates it with Toyota Motor Corporation’s global commitment by 2050. This would refer to the Toyota Environmental Challenge 2050 (Challenge 2050) which has 6 challenges that are the most demanding and most inspiring environmental commitments the world’s No.1 carmaker has ever made. The goals of Challenge 2050 apply to all Toyota subsidiaries around the world, including UMWT which is a joint-venture between United Motor Works (UMW), Toyota Motor Corporation and Toyota Tsusho Corporation.

It is therefore likely to be related to the July announcement about UMWT planning to invest RM270 million for assembly of Toyota hybrid models in Malaysia. The investment will be additional to the RM2 billion that was made the construction and commissioning of a second assembly plant in Bukit Raja, Selangor, which began operations in January 2019.

UMW Toyota Motor to invest RM270 million for assembly of Toyota hybrid models