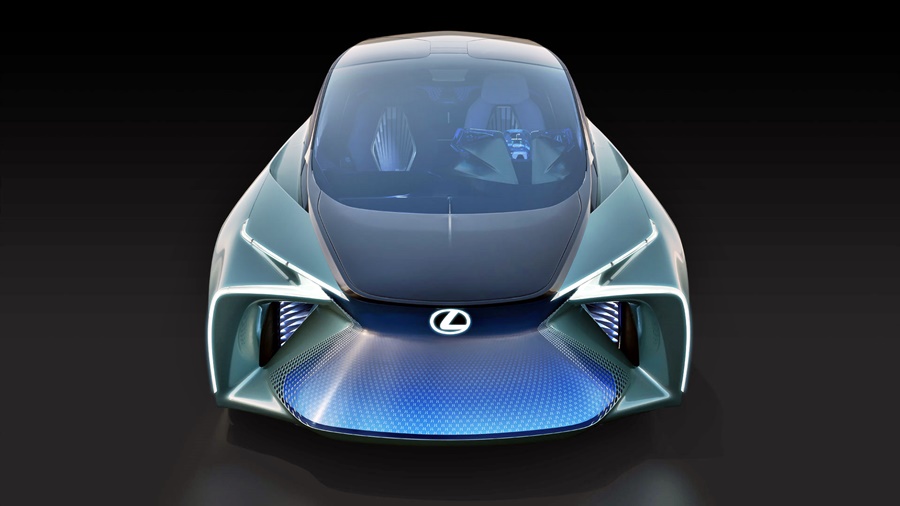

Audi launched its electric offensive with the all-electric Q4 e-tron SUV in September 2018 and by 2025, the carmaker aims to offer more than 20 vehicles with electric drive and achieve roughly 40% of its sales with electrified models.

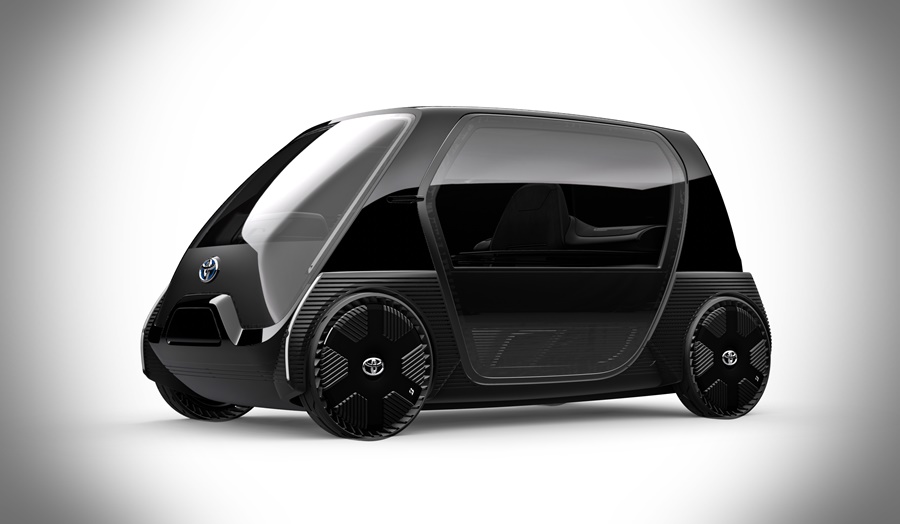

To date, Audi has grown its electrified range to six models and the seventh will be the Q4 Sportback e-tron SUV coupe will be launched next year. Previewing the second e-tron SUV model as a concept study for now, Audi’s aim is to give potential Q4 customers the opportunity to start thinking about which version they prefer roughly a year before the first vehicles will be delivered.

MEB and its importance

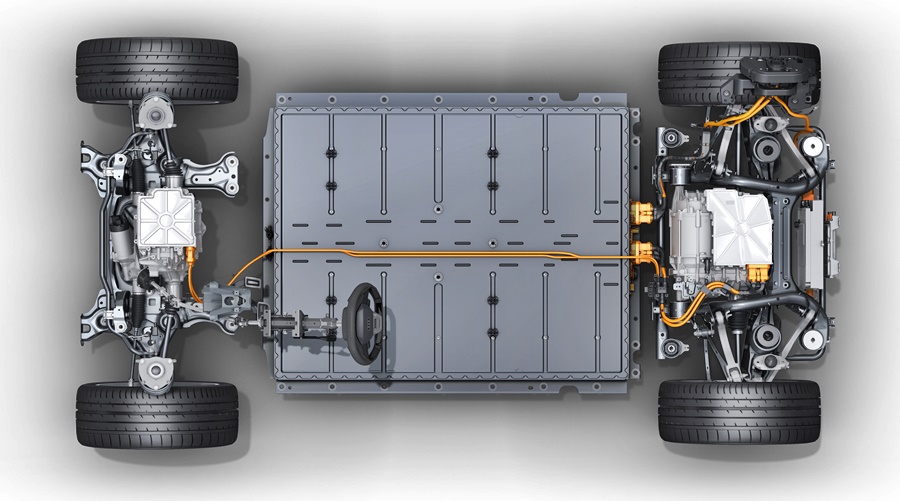

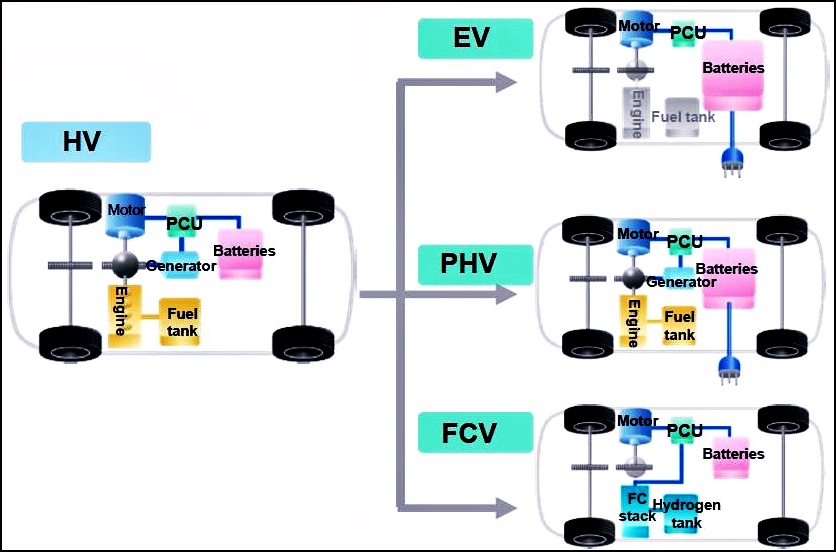

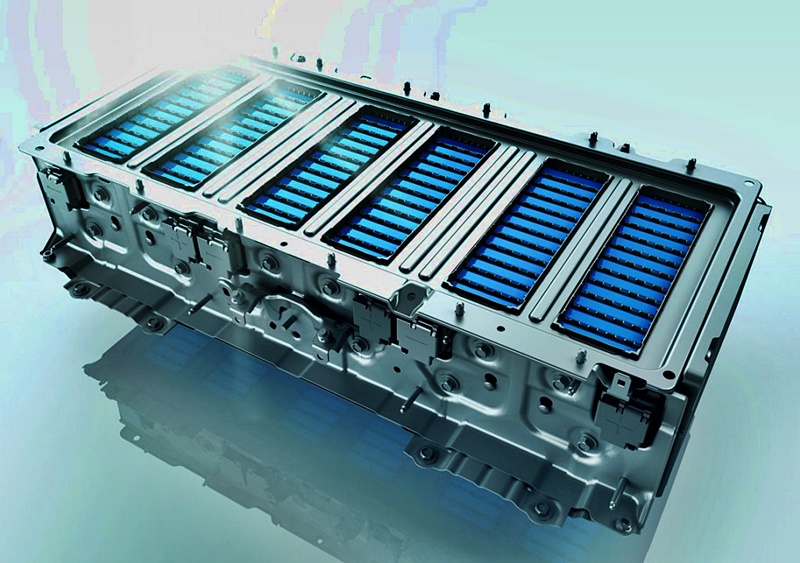

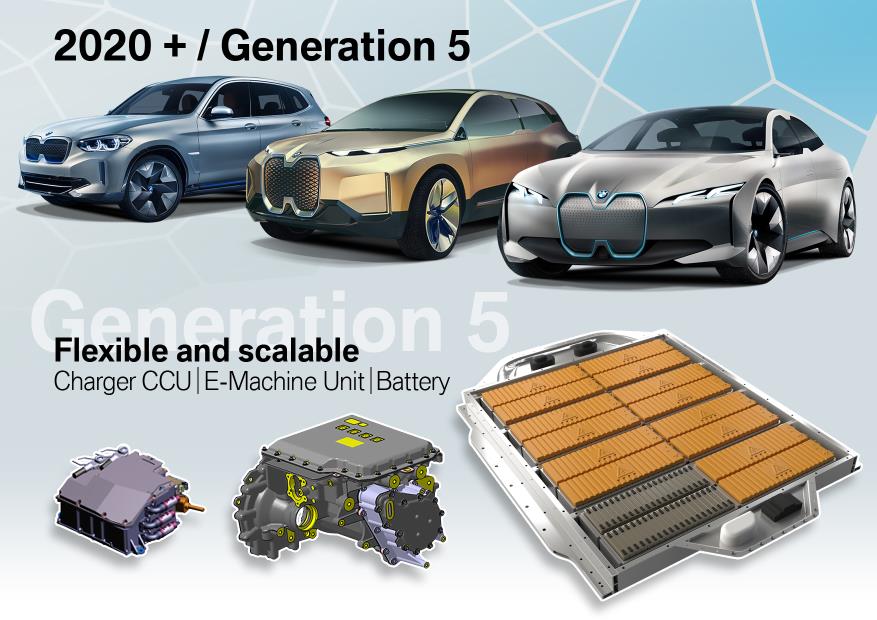

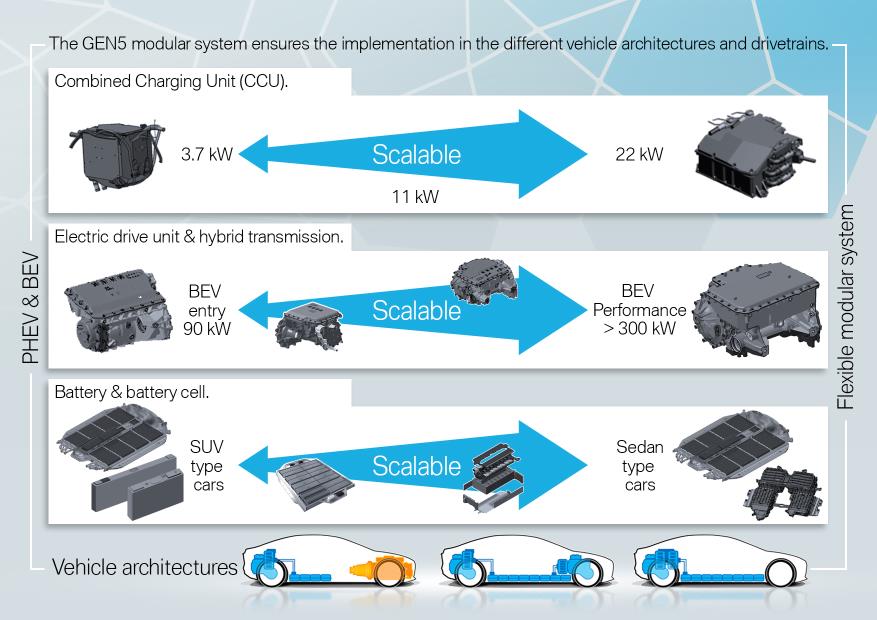

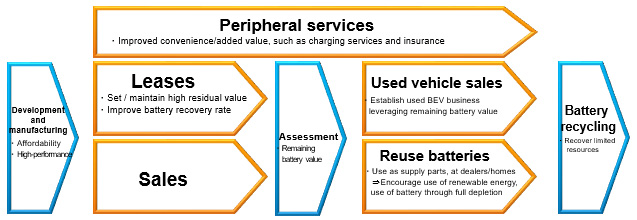

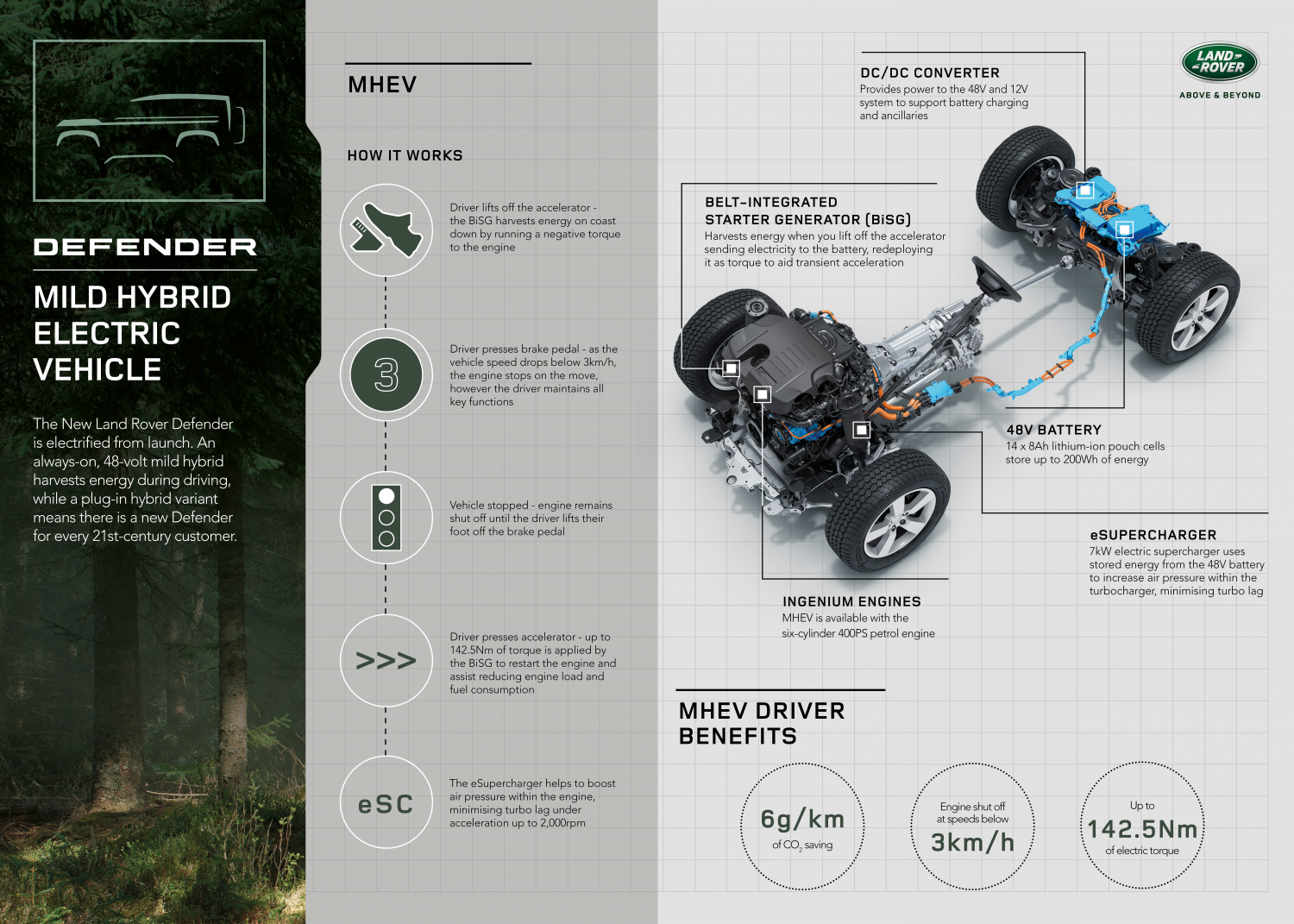

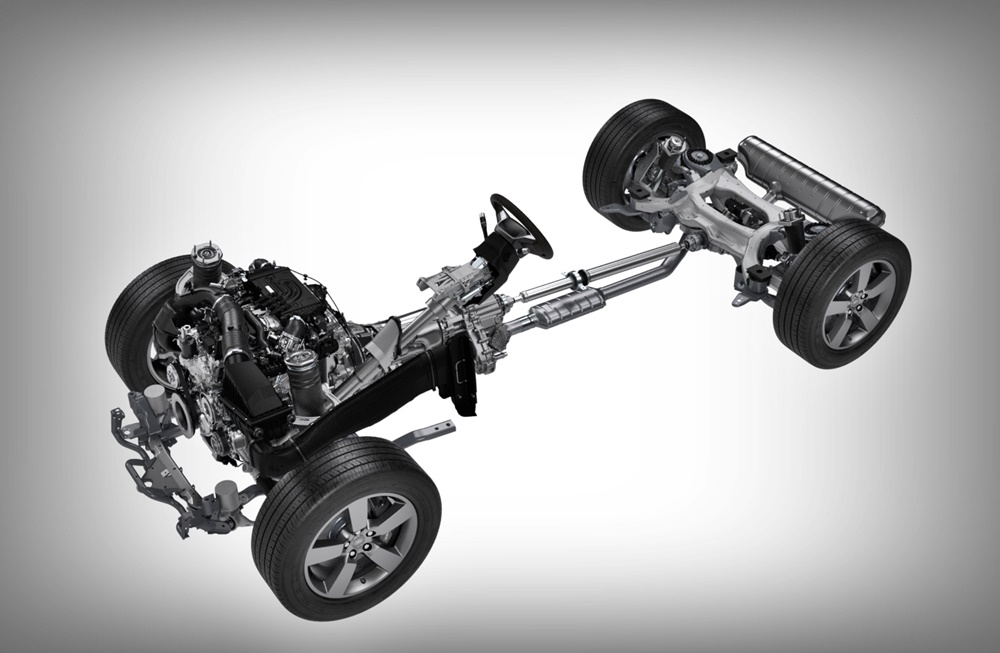

The technology of the Q4 e-tron concept is provided by the modular electrification platform (MEB), which will be used for numerous electric vehicles produced by the Volkswagen Group in the future. This platform serves as the basis primarily for electric cars in the high-volume A segment. It allows the best technology available to be developed jointly across brands and used in many different electric cars. The MEB thus also helps electric mobility to break through even in the particularly price-sensitive compact segment.

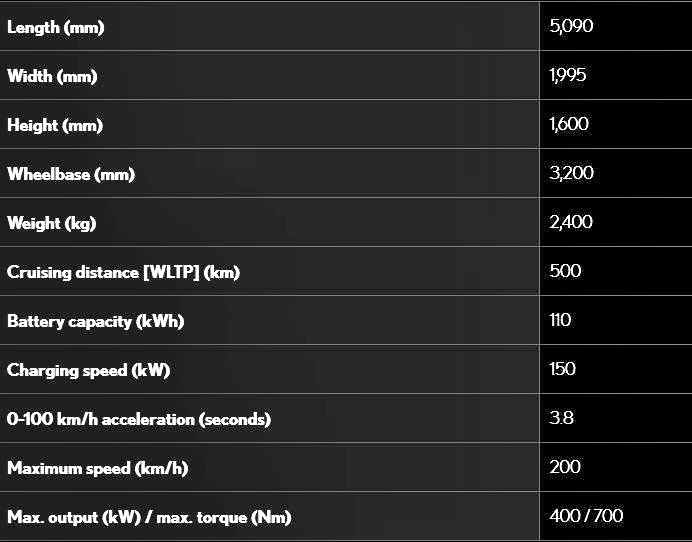

The dimensions of the two Q4 models are almost identical. With an exterior length of 4.6 metres and a height of 1.6 metres, the Sportback is just 1 cm longer and flatter. They are identical in terms of their width and wheelbase.

They will also have the same drive technology using two electric motors with 225 kW of system output. Claimed acceleration from 0 to 100 km/h is 6.3 seconds, with the top speed restricted to 180 km/h.

Electric quattro

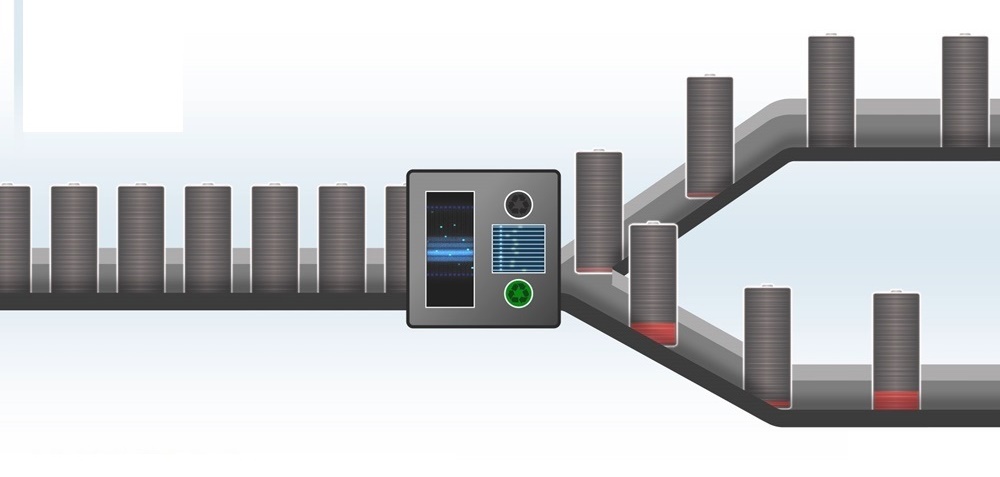

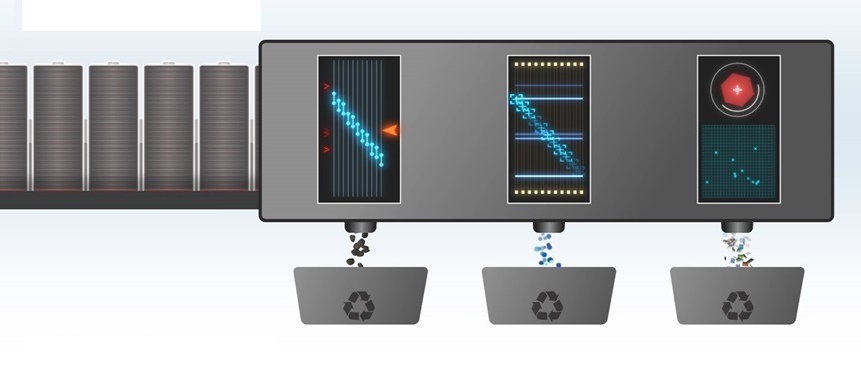

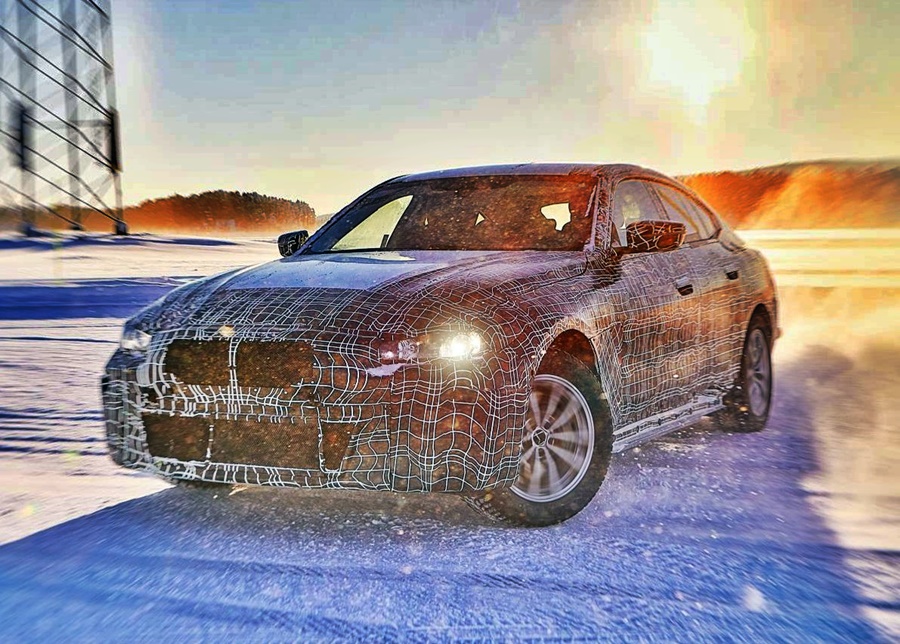

The quattro all-wheel drive system sends the power to the road but there is no mechanical connection between the axles. Instead, an electronic control ensures that the torque distribution is coordinated optimally, and it does so in fractions of a second.

In most cases, the Q4 Sportback e-tron concept mainly uses its rear electric motor in order to achieve the highest efficiency. For reasons of efficiency, the drive torque is generally distributed with a rear-axle bias. If the driver requires more power than the rear electric motor can supply, the electric all-wheel drive uses the front asynchronous motor to redistribute the torque as required to the front axle. This also happens predictively even before slip occurs in icy conditions or when cornering fast, or if the car understeers or oversteers.

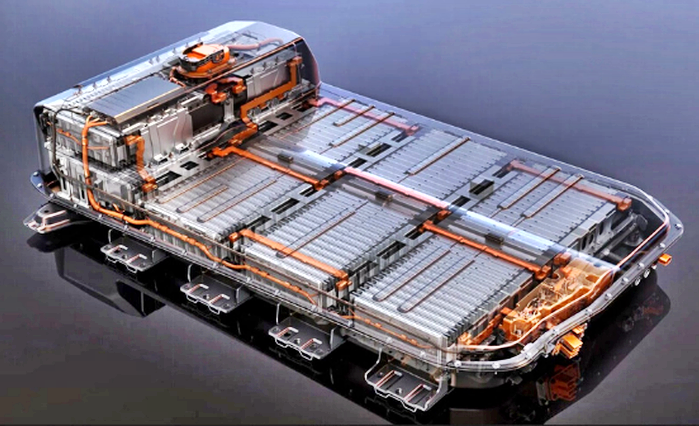

A large battery pack with a capacity of 82 kWh takes up almost the entire space in the underbody area between the axles. The range claimed from a fully charged pack is over 450 kms. Versions with rear-wheel drive can go further, with a range of over 500 kms. The battery is charged with a maximum of 125 kW, requiring little more than 30 minutes to reach 80% of the total capacity.

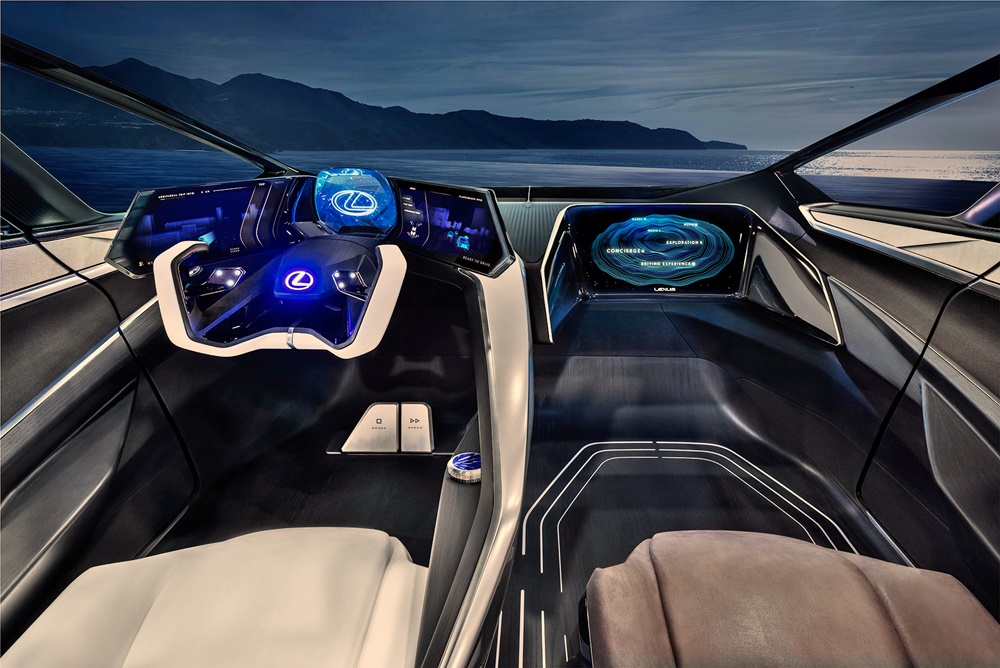

Sense of spaciousness

With its dimensions, the Q4 Sportback e-tron concept takes its position in the upper third of the compact class. By contrast, its wheelbase of 2.77 metres puts it at least one class higher. As there is no transmission tunnel restricting the space, there is generous legroom at the front and even more in the rear.

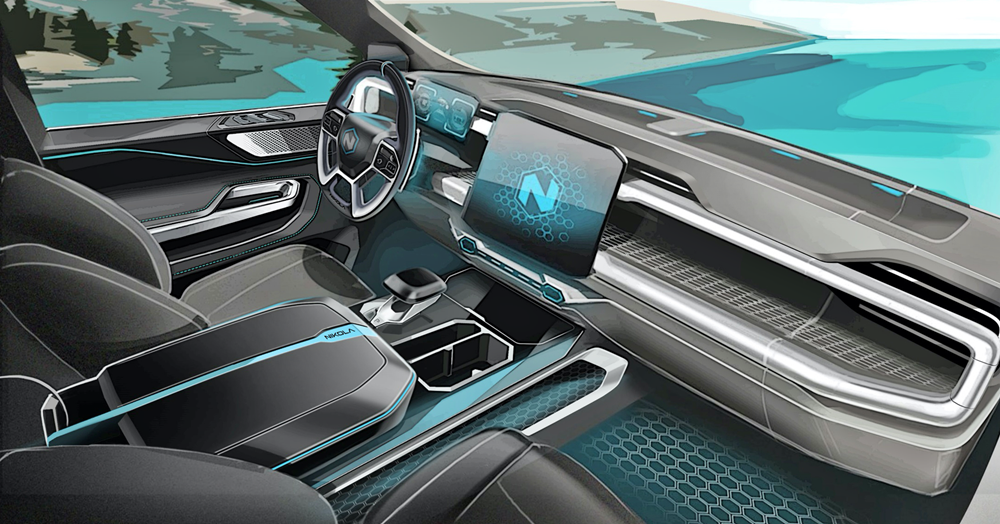

The colour scheme in the cabin emphasizes the sense of spaciousness. Sustainability is the top priority not only in terms of the electric drive but also materials used. The floor covering, for example, is made of recycled materials.

The Audi virtual cockpit displays the main elements for speed, charge level, and navigation, while a large-format head-up display with an augmented reality function is a new feature. It can display important graphical information, such as directional arrows for turning, directly on the course of the road.

As the centre console does not need to hold functional elements such as a gearlever or handbrake lever, the area is used for a more spacious stowage compartment that includes a cell phone charging cradle. In addition to the conventional lower storage compartment, the doors now provide the possibility to store bottles in the specially molded upper section, where they are easy to reach.