Carbon dioxide or CO2 is one of the gases that cause climate change and while this gas is present naturally, a lot is also generated by modern industries as well as internal combustion engines. To limit, if not stop, climate change, governments in many regions have introduced regulations that will force a reduction in emissions of CO2.

For the auto industry, various approaches are being taken in all aspects, not just the products but also the manufacturing processes in the factories. Among the approaches being taken by Mercedes-Benz AG is the use of CO2-free steel in its production vehicles. It is the first car manufacturer to take an equity stake in Swedish start-up H2 Green Steel (H2GS) as a way to make this move.

Prevention and reduction, rather than compensation

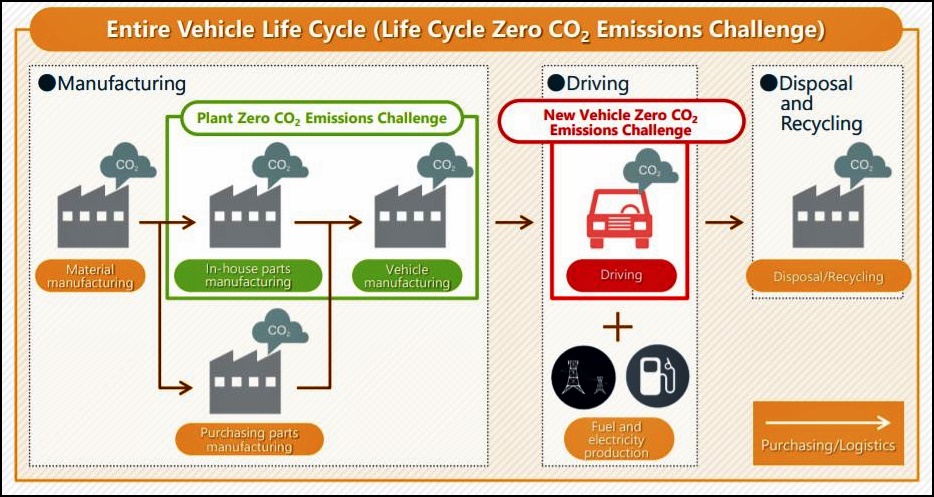

Together with its steel suppliers, the company is retooling its supply chain to focus on the prevention and reduction of CO2 emissions rather than compensation. The partnership with HSGS is another step towards CO2 neutrality, which Mercedes-Benz is pursuing as part of Ambition 2039, its goal to achieve a fully connected and CO2-neutral vehicle fleet in 2039 – 11 years earlier than the EU legislation requires.

A Mercedes‑Benz sedan is, for example, made from about 50% steel, which accounts for about 30% of CO2 emissions in production. With the partnership, Mercedes-Benz is actively and consistently tackling one of the biggest challenges in the automotive industry on the road to CO2 neutrality.

Accelerate change in steel industry

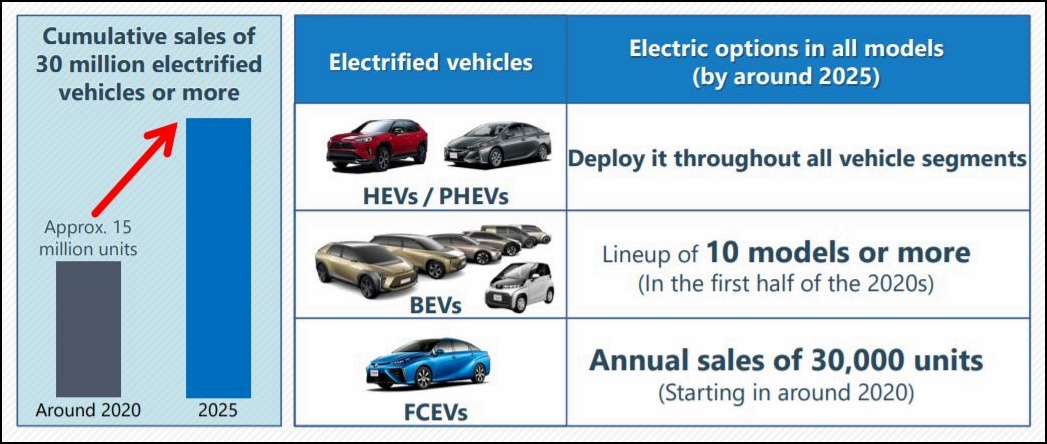

“With an equity stake in H2 Green Steel, Mercedes-Benz is sending an important signal to accelerate change in the steel industry and increase the availability of carbon-free steel. As a first step, we are investing a single-digit million amount. As a preferred partner of the start-up, we will be launching green steel in various vehicle models as early as 2025,” said Markus Schafer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG; responsible for Daimler Group Research and Mercedes-Benz Cars COO.

H2GS, founded in 2020, will produce 5 million tons of fossil-free steel by 2030. By doing this, the company will contribute to the decarbonizing of the European steel industry, one of the largest carbon dioxide emitters.

CO2-free manufacturing technology

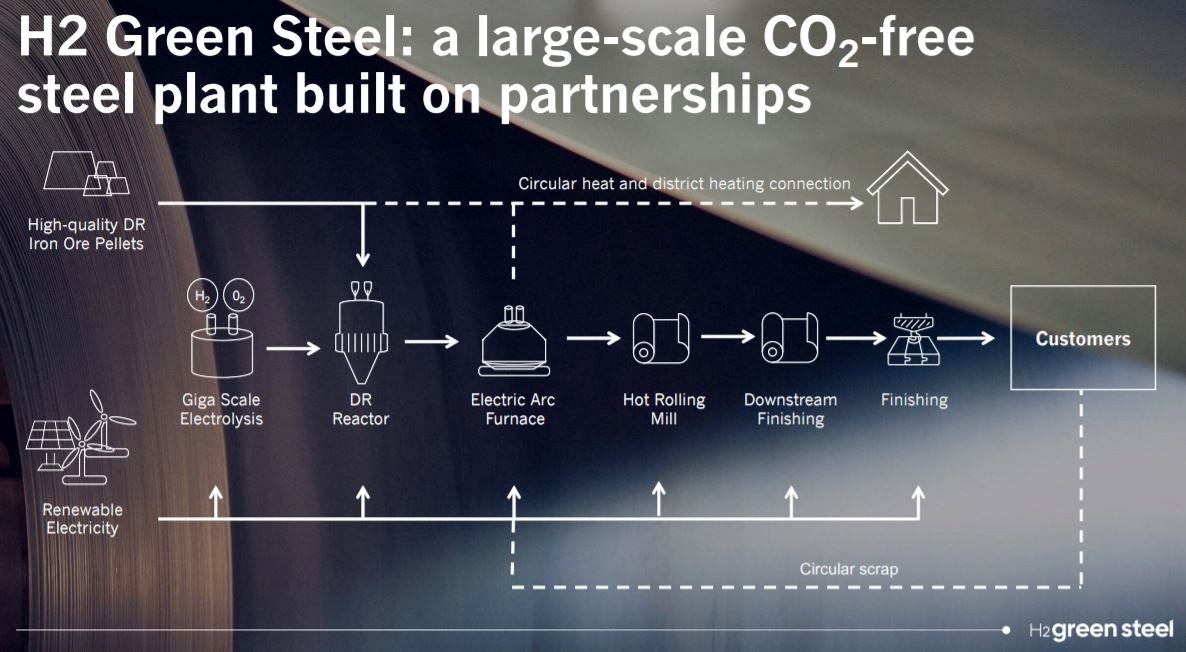

By using a new, innovative manufacturing process, the production of steel at the supplier level is CO2-free. By contrast, steel produced using a traditional blast furnace emits an average of more than 2 tons of CO2 per ton. In the new process, the supplier uses hydrogen and electricity from 100% renewable energy sources instead of coking coal in steel production.

The hydrogen serves as a reduction gas, which releases and binds the oxygen from the iron ore. Unlike the use of coking coal, this does not produce CO2, but water. The supplier uses electricity from 100% renewable sources for the energy requirements generated in the manufacturing process.

Sustainable steel supply chain

Mercedes-Benz and all its steel suppliers are working consistently to reduce CO2 emissions in the steel supply chain on the way to producing green steel. In addition, the company is committed to a responsible steel supply, relying on the application of recognized standards and robust certificates. Mercedes-Benz is a member of the Responsible Steel Initiative and is actively involved in the development of a certifiable sustainability standard for the steel industry. The aim is to ensure environmentally friendly and socially acceptable steel production along the entire value chain.

Future Mercedes-Benz supply chain

Mercedes-Benz AG pursues the goal of a CO2-neutral new car fleet along the entire value and supply chain. Suppliers representing more than 85% of Mercedes-Benz’s annual purchasing volume have already signed an Ambition Letter, agreeing to supply the company only with CO2-neutral products in the future. This includes important steel suppliers. At the same time, Mercedes-Benz is working with its partners to gradually increase the proportion of secondary materials in components and materials.

Mercedes-Benz battery pack production facility in Thailand begins operations