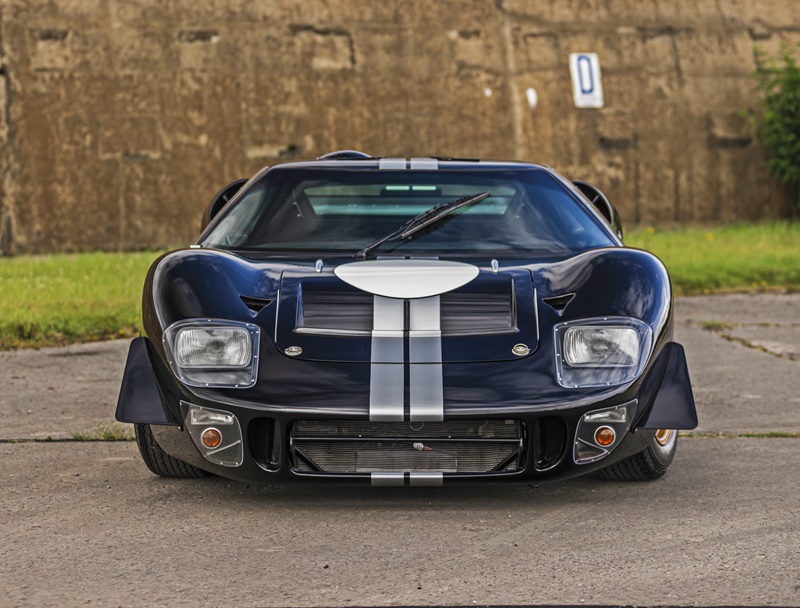

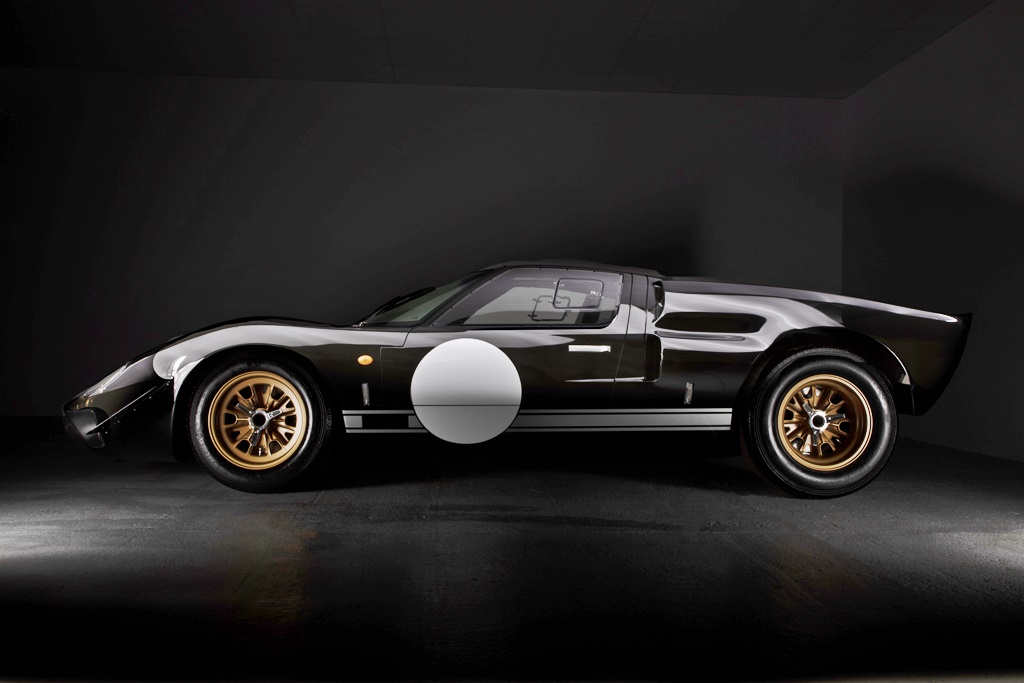

A couple of months back, we wrote about Everrati Automotive Limited and its new flagship 500-bhp Signature adapted from a Porsche 911. The British company, which specialises in converting iconic cars to run with electric powertrains, has now teamed up with Superformance to build an electrified version of the GT40.

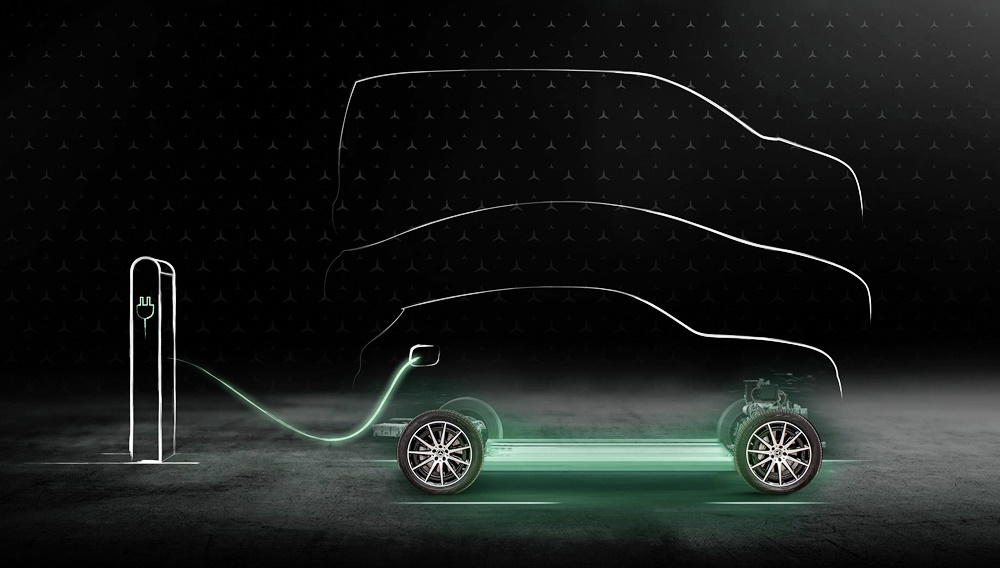

Superformance is a specialist in 1960s-era continuation component sports cars and the GT40 will be the first new model from the partnership. The iconic endurance racing car will be ‘future-proofed’ with a high-performance electrified powertrain and join Everrati’s offerings. The range includes EV versions of the Porsche 911 (964), Land Rover Series IIA and Mercedes-Benz SL Pagoda.

Furthering the legacies of iconic cars

Everrati was founded to further the legacies of some of the most desirable and iconic cars in the world, redefining and precision re-engineering them with state-of-the-art electric drivetrains, maintaining and enhancing the character of the original.

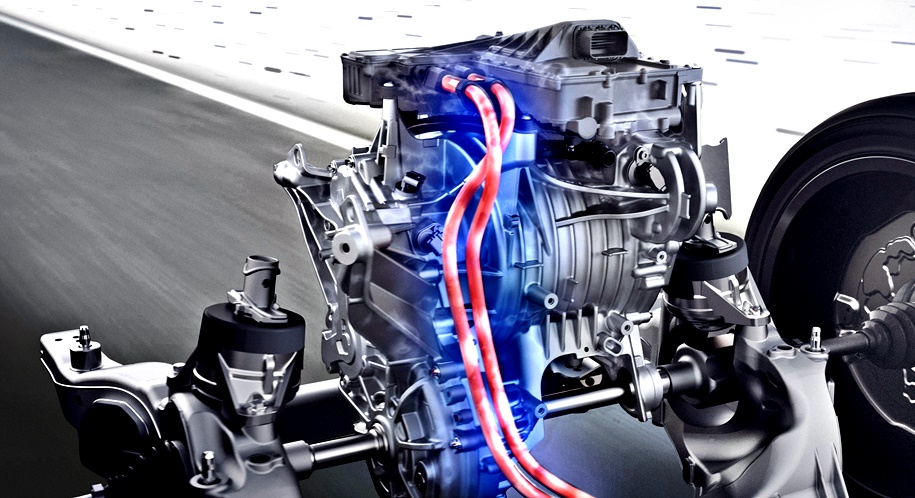

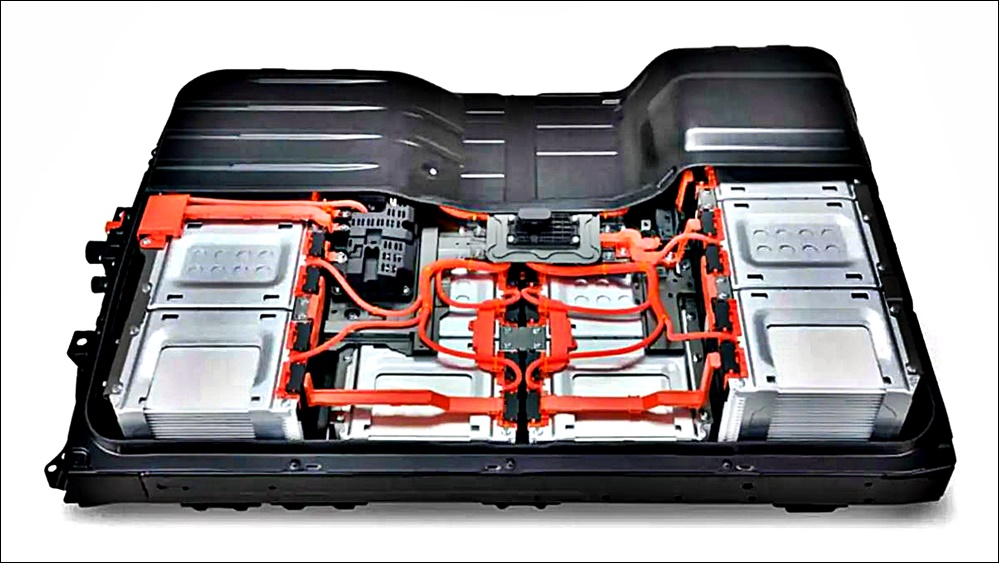

Each Everrati is fitted with a custom-designed electric power unit and battery system, leading to enhanced performance and a zero-emissions future. A prototype chassis has been built and is being comprehensively adapted from combustion engine powertrain to advanced electric propulsion at Everrati’s UK development centre located at a former US airbase in England.

Superformance already offers a full line of high-performance component cars based on some of the most iconic vehicles of all time. All vehicles are built under license from trademark holders including GM and SAFIR GT40, adding authenticity and value. Sold as a rolling chassis, a Superformance car can be configured with heritage or modern drivetrains.

As with all Everrati vehicles, meticulous attention to detail is being applied to key factors such as battery location and weight distribution to maintain and enhance the character and soul of the original.

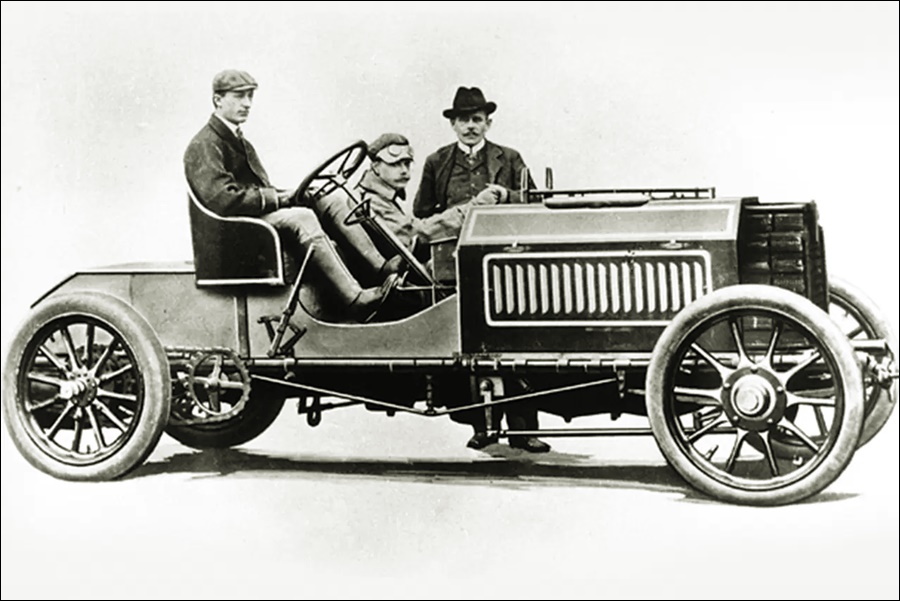

Angle-American partnership

“So many legendary cars were created by Anglo-American partnerships during the 1960s. In fact, the very first GT40 was brought to life in the early Sixties by a UK-based team led by British engineer, Roy Lunn, at Ford Advanced Vehicles in the UK. Its body was even made by Abbey Panels in Coventry, before the finished car was shipped to the US for its unveiling the day before the New York Auto Show, in April 1964,” noted Justin Lunny, Founder & CEO of Everrati.

“So, it feels highly appropriate for Everrati to be partnering with Superformance, furthering not only the legacy of automotive icons but the partnership between the UK and US. Another cross-Atlantic connection is that our development HQ is located on a former US air base in the Oxfordshire countryside,” he added.

The Superformance factory in California is one of the world’s largest specialty car production facilities. It has produced and distributed more than 5,500 rolling chassis through 25 independent dealerships worldwide.

Everrati Signature Widebody – an electrified Porsche 911 (964)