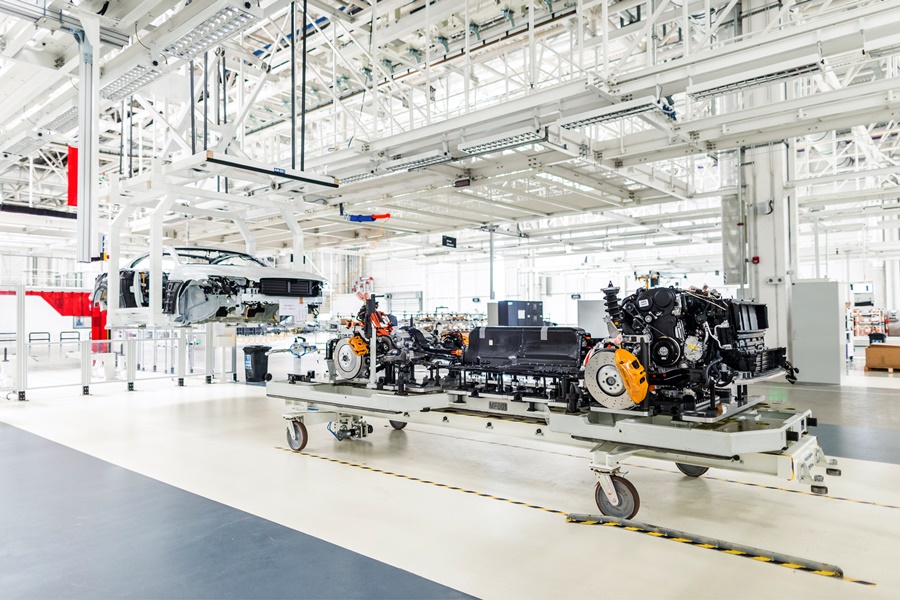

Having received its World Manufacturer Identifier (WMI) that makes it a recognised vehicle manufacturer, Polestar is set to accelerate ahead at its first production facility located in Chengdu, China. This new Polestar Production Centre sets a new industry benchmark in electric vehicle manufacture and will produce the Polestar 1 – an exclusive, carbonfibre-bodied Electric Performance Hybrid.

500 Polestar 1 cars are to be built per year, with a total of 1,500 planned over a 3-year production cycle. Construction of Polestar 1 in Chengdu will be followed by production of the fully electric Polestar 2 in Luqiao, China, in early 2020.

Most premium new energy vehicle

The new facility, which was completed on schedule, will produce cars for both China and global export markets with first customer deliveries expected before the end of 2019. The company presents the Polestar 1 as ‘the most premium new energy vehicle to be manufactured in China’. Included in the manufacturing process is a team of highly trained quality control auditors whom, with a minimum of 10 years of experience, apply some of the strictest monitoring and assessment procedures in the industry.

The Polestar Production Centre aims to be one of the most environmentally responsible car factories in China. Designed by internationally renowned architecture and design company, Snøhetta, the new production facility incorporates a customer experience centre including a test track and a glazed atrium offering a panoramic view over the factory floor.

New standards in manufacturing

“Designing Polestar’s first production facility has been a challenging and extremely rewarding project for us,” said Snøhetta’s co-founder, Kjetil Trædal Thorsen. “The innovative design of the interaction scheme aligns creative visionary processes with technical production requirements, setting a new standard for inclusive fabrication facilities.”

“We promised we would have our first production facility built in 2019; we promised cars would be delivered to customers this year, and we promised we would do things differently – once again, we are delivering on our promises. This is a hugely proud moment for the whole team at Polestar,” said Thomas Ingenlath, CEO of Polestar.

Click here for other news and articles about Polestar