Hydrogen is the most abundant element on earth and when used as an energy source, it does not generate carbon dioxide which is known to cause negative climate change. It thus has great potential as a zero-emission energy source for a variety of products. For this reason, a number of leading global companies are carrying out R&D to develop processes to produce hydrogen efficiently and cost-effectively as well as to make use of it widely.

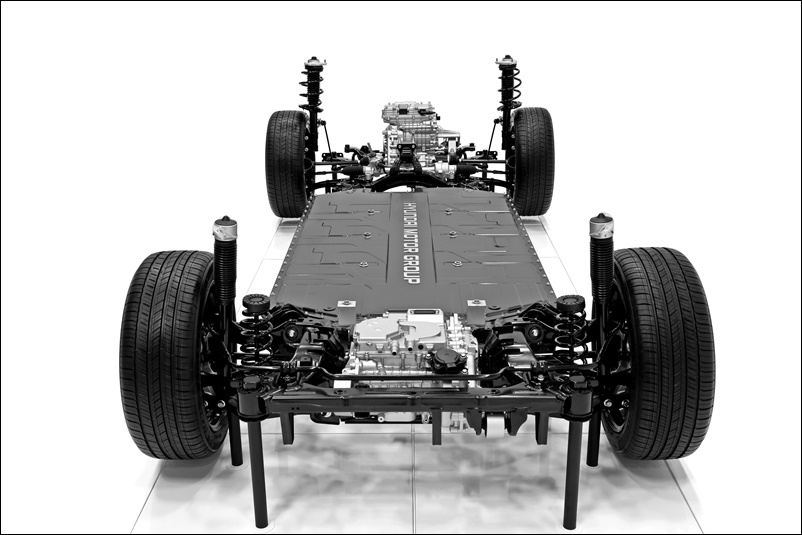

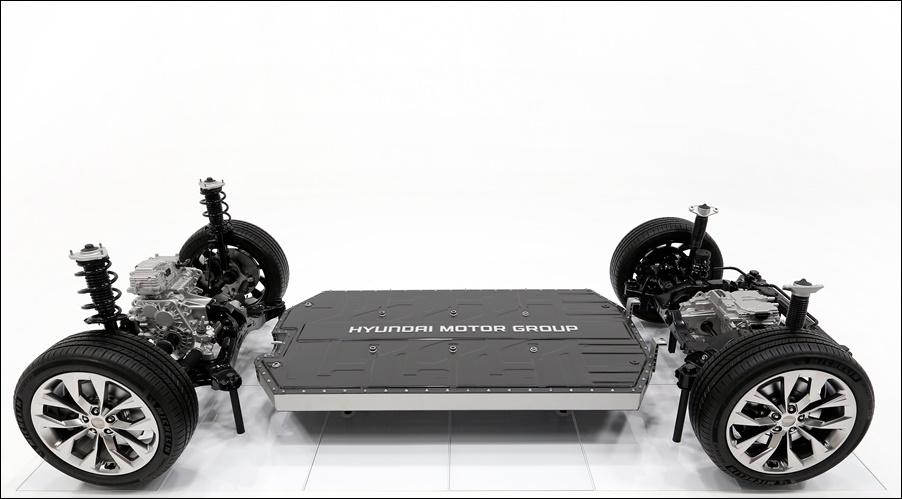

The Hyundai Motor Group (HMG) is among these companies and has announced its Hydrogen Vision 2040 to popularize hydrogen by 2040 for ‘Everyone, Everything and Everywhere’. Hydrogen Wave represents the group’s plans for a new ‘wave’ of hydrogen-based products and technologies toward a hydrogen society.

“By developing advanced technologies and innovative systems – as well as encouraging close collaboration between public and private sectors across the globe – it is possible to make this sustainable vision a reality for all,” said the Chairman of the HMG, Euisun Chung, at the Hyundai Wave global forum online today.

He explained that Hyundai Motor Group’s vision is to apply hydrogen energy in all areas of life and industry such as homes, workplaces and factories. “The goal is to make hydrogen readily used for everyone, everything, and everywhere,” said Mr. Chung. “We want to offer practical solutions for the sustainable development of humanity and with these breakthroughs, we aim to help foster a worldwide Hydrogen Society by 2040.”

Electrification of commercial vehicle models

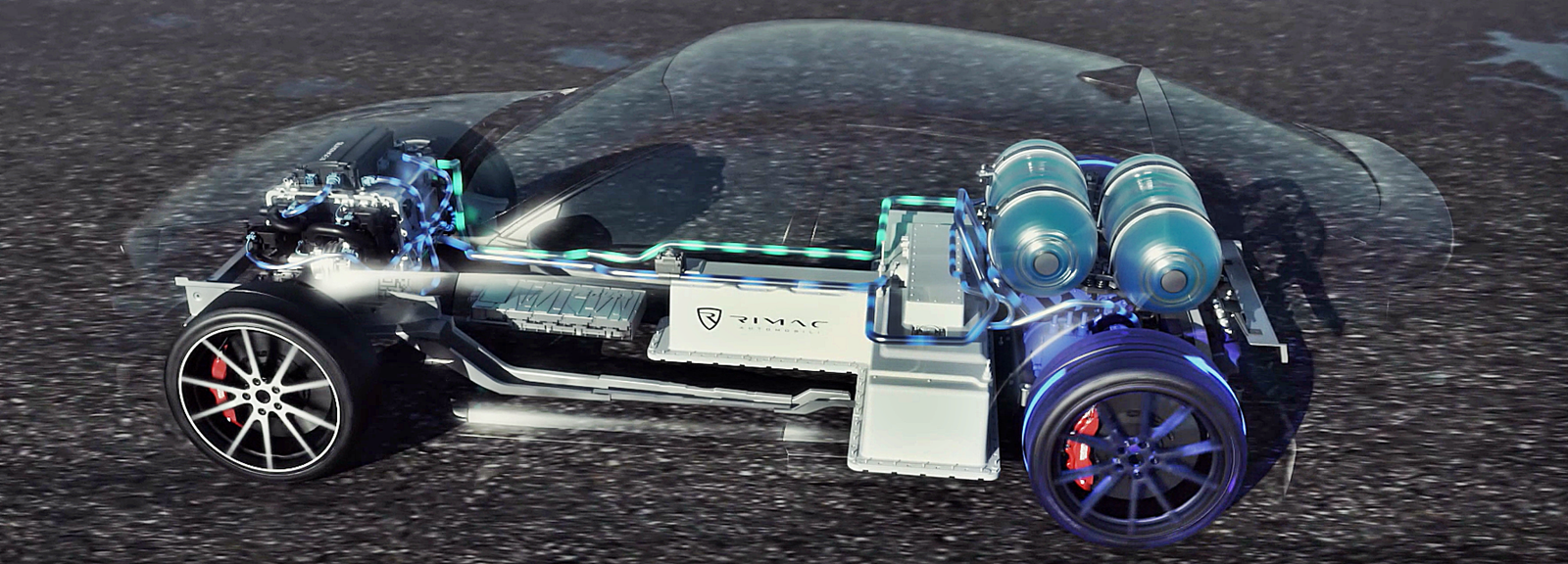

In the context of the auto industry, HMG revealed unprecedented plans that will see the electrification of all new commercial vehicle models – featuring fuel cell electric or battery electric powertrains, as well as the application of fuel cell systems – to all models by 2028. Other future product concepts featuring fuel cell technologies include Trailer Drone, a high-performance sportscar, and fuel cell-equipped vehicles for emergency relief and rescue missions.

Since the development of its first (Fuel Cell Electric Vehicle (FCEV) in 1998, HMG has been preparing for the future of hydrogen. In 2013, the Tucson FCEV (ix35 Fuel Cell) was introduced, opening the door to the mass production of FCEVs. Then, in 2018, the company launched the next-generation fuel cell SUV, the NEXO, with the world’s first heavy-duty fuel cell truck, the XCIENT Fuel Cell, being unveiled last year. After 2 decades of fuel cell technology development, HMG will expand its fuel cell technologies for wider applications of its vehicles, including additional mobility solutions and various energy utilization.

Bringing costs down

Fuel cell systems using hydrogen to generate electricity are not only being used commercially for vehicles today but also have the potential for deployment across diverse applications by 2040. To achieve this, HMG is planning to introduce a new generation fuel cell system in 2023 with a reduced price and volume while also having significantly improved durability and output.

Through ongoing R&D gains, engineering teams have been able to reduce fuel cell costs drastically over the last 20 years. By ensuring price competitiveness, the goal is to achieve a fuel cell vehicle price point comparable to a battery electric vehicle (BEV) by 2030. Economies of scale of hydrogen production can be realised by continuous technological innovation of fuel cell systems as well as close collaboration with other organizations and governments across diverse business areas.

Next-generation fuel cell systems

HMG has developed a series of new fuel cell systems including a new prototype of its third-generation fuel cell stack. This is a higher-powered, efficiently packaged successor to the NEXO system that is planned for market introduction in 2023. Currently still in development, the third-generation fuel cell stack has 2 power versions – 100 kW and 200 kW.

The 100 kW stack has reduced in size by 30%, making it easier to apply to different vehicle types and applications. The 200 kW version is intended for commercial vehicle applications and is similar in size to the current NEXO system, but the power output has doubled.

High durability stacks for commercial vehicles will achieve 500,000 kms of drive range. Furthermore, the price of the third-generation fuel cell stack will be dramatically reduced – with projections being more than 50% – which will be the key factor to achieving cost parity of FCEVs with BEVs by 2030.

HMG will continue to develop hydrogen mobility, expand the production system of fuel cells and establish infrastructures for a global hydrogen society. “The degree and frequency of environmental disasters is rising fast, and we now face a code red warning for humanity,” said Mr. Chung. “The Group seeks to offer powerful and pragmatic solutions for combatting climate change via the tremendous potential of hydrogen energy.”

HydroVILLE to showcase hydrogen vision

Following the Hydrogen Wave forum, HMG will be presenting its plans for hydrogen energy and a global hydrogen society at its ‘Hydrogen Village’ (HydroVILLE) exhibition in Goyang, Korea, this week. HydroVILLE’s various zones will illustrate the Group’s future hydrogen vision. The exhibition space features several fuel cell concepts for future mobility and power generation, including 18 models from Hyundai Motor Group affiliates such as Hyundai Motor, Kia, Hyundai Mobis, Hyundai Rotem, Hyundai Steel, Hyundai Wia and Hyundai Kefico.

Hyundai IONIQ 5 EV to be used for fully autonomous robotaxi by Motional