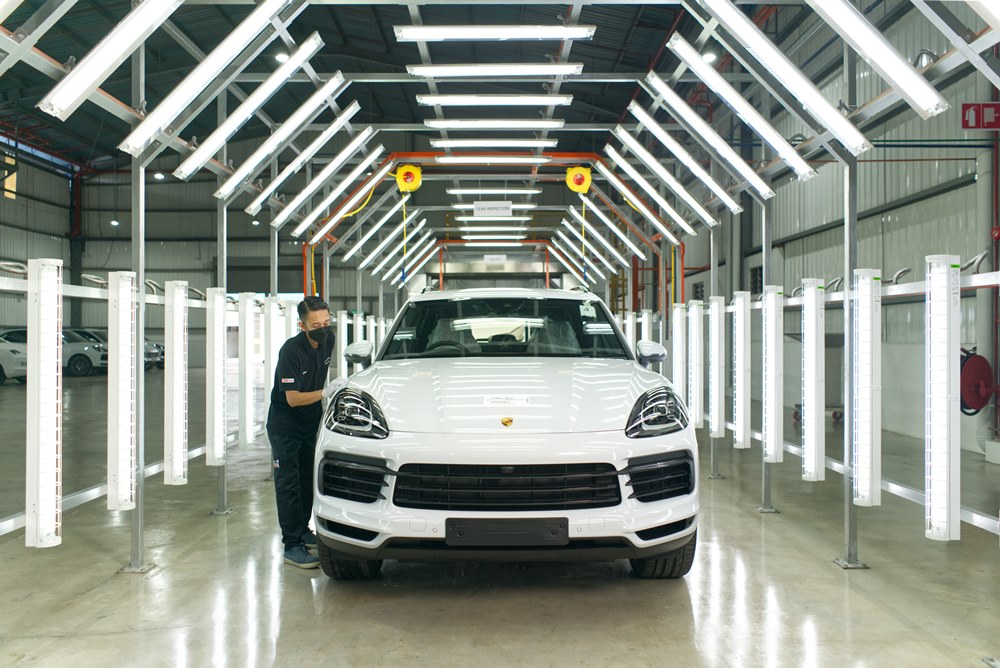

Dinamikjaya Motors Sdn Bhd, the exclusive distributor of the renowned Kia brand in Malaysia, has unveiled the locally assembled Kia Carnival 11-seater variant, now open for booking at an attractive selling price of RM213,888. This milestone sees the Kia Carnival 11-seater become the third Kia model to be locally assembled at the Inokom Assembly plant in Kulim, Kedah.

The fourth-generation Kia Carnival exhibits a design evolution that pays homage to its predecessors’ legacy, introducing a more robust architectural presence and an enhanced aesthetic that adheres to Kia’s overarching design philosophy, connecting all of Kia’s automotive creations.

Interior

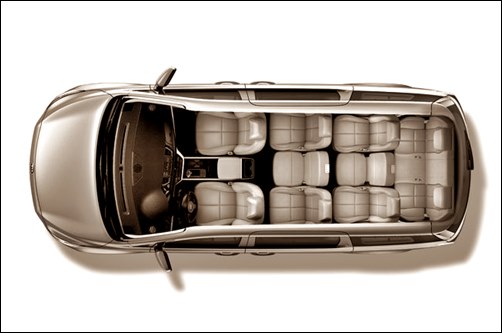

Inside the Kia Carnival, the interior concept revolves around “Spatial Talents,” thoughtfully conceived by Kia’s design teams. This approach results in an environment that exudes spaciousness, comfort, and a futuristic aura, catering to young families. The Kia Carnival offers a unique blend of innovation, versatility, and style, catering to both drivers and passengers. Like its forerunner, it provides abundant space for passengers in all rows, now imbued with a heightened sense of modernity and sophistication.

It boasts a standard Black and Gray leatherette interior finishing. Notably, the specifications of the Carnival 11-seater remain unaltered, encompassing front styling and LED daytime running lights (DRLs), Smart Power Sliding doors, Smart Power Liftgate, Smart key with one-button open/close function for the rear sliding door and liftgate.

Technological Prowess

This 11-seater doesn’t hold back on technology either. It features a 12.3-inch High-resolution LCD Touchscreen Infotainment system with Apple Carplay and Android Auto compatibility, wireless smartphone charging, versatile multi-Bluetooth connectivity, and an impressive seven USB ports.

Safety First

Safety is paramount, with the 11-seater Carnival being equipped with a comprehensive array of standard and advanced safety features. These encompass 7 SRS Airbags, Anti-Lock Braking System (ABS), Electronic Stability Control (ESC), Traction Control System (TCS), Multi-Collision Brake Control (MCB), ISOFIX Child Restraint Anchor Points, Top Tethers, and Hill-Start Assist Control (HAC). Notably, the Carnival also incorporates Blind-Spot Collision Warning (BCW) and Rear Cross-Traffic Avoidance Assist (RCCA).

Powerful Performance

At its heart, it houses a robust 2.2L Turbo Diesel Engine, seamlessly paired with an 8-speed automatic transmission, managed by an electronic shifter (E-Shift). This powertrain generates 199hp at 3,800 RPM and a substantial 440Nm of torque, available between 1,750 and 2,750 RPM. The result is a smooth, linear acceleration and an exhilarating driving experience.

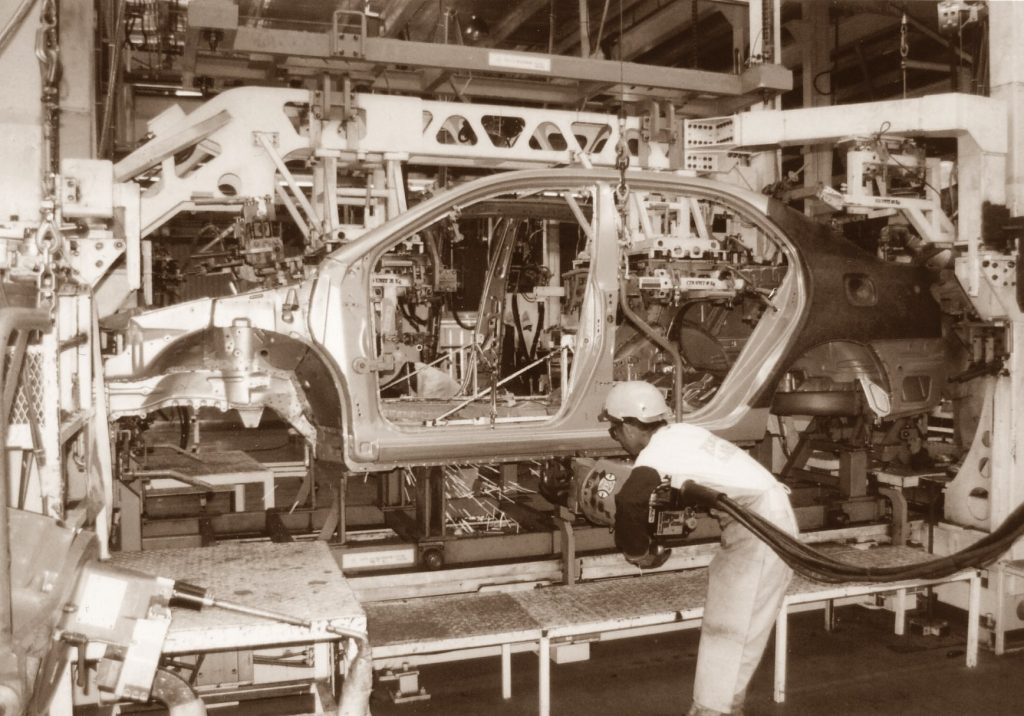

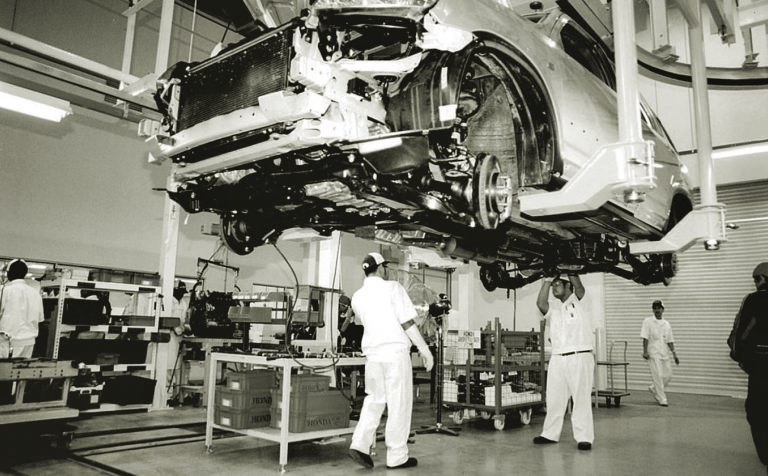

The Kia Carnival 11-seater is now locally assembled in a CKD (Completely Knocked Down) format at the Inokom Assembly Plant situated in Kulim, Kedah. The available color options include Astra Blue, Snow White Pearl, Meteor Gray, and Jet Black, offering a total of four captivating choices.

Special Introductory Offer

To celebrate this launch, there is an exclusive introductory offer selling price of RM198,500.00, inclusive of accessories, for all bookings from 1st November to 31st December 2023.

Warranty and Maintenance

It comes with a 5-Years Manufacturer Warranty, covering up to five years or 100,000km, whichever comes first. Furthermore, it includes 5-Years Free Scheduled Maintenance, with coverage extending up to five years or 100,000km, whichever comes first.

The Kia Carnival 11-seater will be showcased at the Bermaz Auto Showcase event which will take place from 1st – 5th November 2023 at Centre Court, Pavilion Bukit Jalil from 10:00AM to 10:00PM.