Almost every day, there’s news about the electrification in the auto industry, if not the introduction of a new electric vehicle (EV). The industry, especially in Europe, has fast-tracked plans to move existing model fleets from using internal combustion engines to either hybrid or fully electric powertrains. Some companies even plan to stop selling vehicles with combustion engines before the end of this decade.

But there are also some companies that will look for a balance in the rush to electrification, focussing more on overall carbon neutrality (which can address climate change) for their entire operations, rather than just the products alone. Akio Toyoda, President of Toyota Motor Corporation, is one of those who feels that the rush to switch to zero emission vehicles is too excessive, demands massive investments and will damage the industry in some ways.

Whole world won’t ‘electrify’ at the same time

While governments are forcing the corporate hands of the carmakers to make the changes and cut emissions from vehicles, there will still be models with combustion engines on sale for a while. We don’t know yet how fast the infrastructure to support EVs can be developed and grow because, in some places, it doesn’t even exist yet. In Malaysia, for example, the number of recharging stations already set up is really just ‘a handful’ and an absence of a coherent policy to encourage sales and use of EVs has yet to be formulated.

So while some carmakers may feel that they can get by (in future) selling just EVs, there will be some who will still be developing models with combustion engines for the rest of this decade at least. Engineers can still push emissions down further to meet stricter regulations and a new generation of fuels will also help in this respect.

Renewable low-carbon fuels

These are renewable low-carbon fuels and following on from R33 Blue Diesel which has been around since 2018, Bosch, Shell, and Volkswagen have now come up with low-carbon petrol. Their new fuel, called Blue Gasoline, similarly contains up to 33% renewables, ensuring a well-to-wheel reduction in carbon emissions of at least 20% per kilometre driven. This means a fleet of 1,000 VW Golf Mk.8 1.5 TSIs alone could save more than 230 metric tons of CO₂ per year, assuming an annual mileage of 10,000 kms each.

Shell will offset the remaining carbon emissions from the use of Blue Gasoline through certified offset arrangements. The initial plan is to make the fuel available at regular filling stations over the course of the year, starting in Germany.

“On the road to climate-friendly mobility, we must ensure we don’t leave any technical opportunities untapped, starting with electromobility and ending with renewable fuels. Every bit of CO₂ we save can help us achieve our climate targets,” said Dr. Uwe Gackstatter, President of the Bosch Powertrain Solutions division.

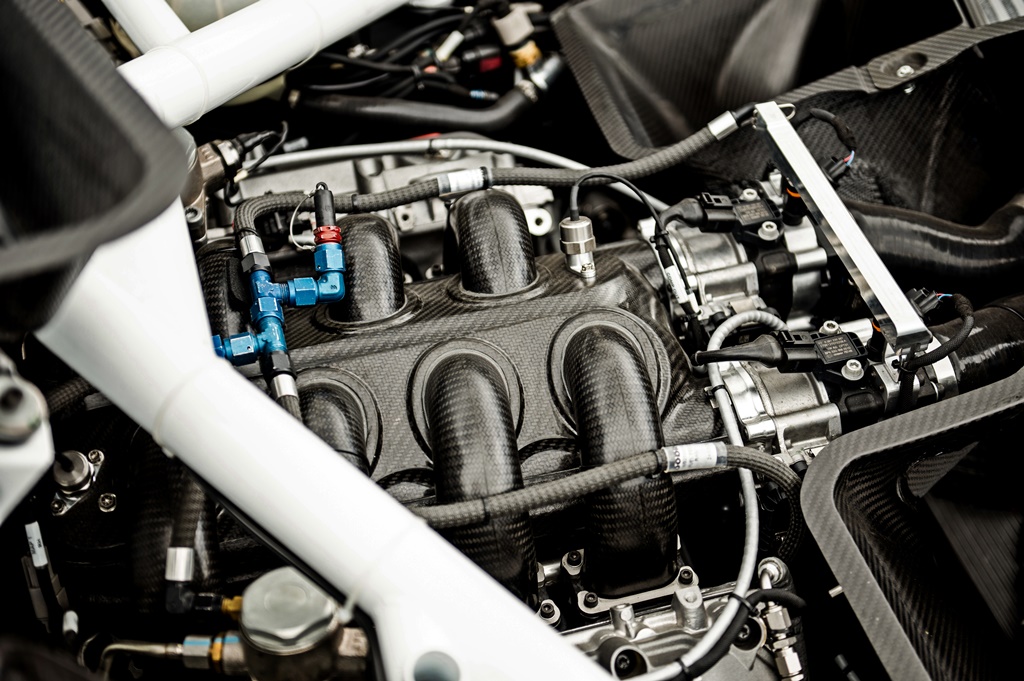

“Blue Gasoline is another building block in the effective reduction of CO₂ emissions from the vehicle fleet. Blue Gasoline’s high storage stability makes the fuel particularly suitable for use in plug-in hybrid vehicles. In the future, the expansion of the charging infrastructure and larger batteries will mean that these vehicles predominantly run on electrical power, and thus that fuel may remain in the fuel tank for longer periods of time,” explained Sebastian Willmann, Head of Internal Combustion Engine Development at Volkswagen

Highest standards set for fuel quality and sustainability

Blue Gasoline fuel complies with the EN 228/E10 standard and even exceeds it in key parameters such as storage stability and boiling behaviour. High-quality additives also keep the engine extremely clean and protect it against corrosion. This means not only that the fuel can be distributed via the existing filling station network, but also that it can be used in all new and existing vehicles for which Super 95 E10 petrol has been approved.

The proportion of up to 33% renewables is made up of biomass-based naphtha or ethanol certified by the International Sustainability and Carbon Certification (ISCC) system. One source of such naphtha is what is known as tall oil, a by-product in the production of pulp for paper. But naphtha can also be obtained from other residual and waste materials.

Low-carbon fuels at Bosch company stations

In the Blue Gasoline project, the three partners jointly defined the fuel specification to be achieved, taking into account engine requirements and sustainability. They put the product they developed through intensive testing on engine test benches and in trial vehicles – with consistently positive results. Bosch has begun supplying Blue Gasoline at its company filling stations for the past month, with other stations scheduled during for rest of 2021.

The supply of conventional Super 95 E10 petrol will then be gradually phased out. Since the end of 2018, R33 Blue Diesel has been the only diesel fuel that Bosch company filling stations offer for company cars and internal delivery vehicles. R33 Blue Diesel is also becoming available at more and more regular filling stations in Germany. At present, it is offered at 8 filling stations belonging to different brands nationwide, with more set to follow.

Not a substitute for electromobility

For Bosch, renewable low-carbon and carbon-neutral fuels will not replace electromobility but complement it. In principle, the use of these fuels makes sense in all modes of transport, but especially in those for which there is as yet no clear and economical path to electrification. In addition to ships and aircraft, this applies primarily to heavy goods vehicles and existing vehicles, but also to the millions of vehicles with internal combustion engines or hybrid powertrains that are on the world’s roads today or will be built in the coming decades.

To promote rapid market uptake for these fuels, the focus is on renewable biomass and synthetic fuel components that can be blended into regular fuel in high proportions in line with existing fuel standards.