Our older readers will remember the dynamo which was a small device rotated by the bicycle wheel. As it rotated, sufficient electricity was generated to light up the lamp. That simple idea of using the tyres to indirectly generate electricity is being revived with a new technology being developed by engineers in Japan.

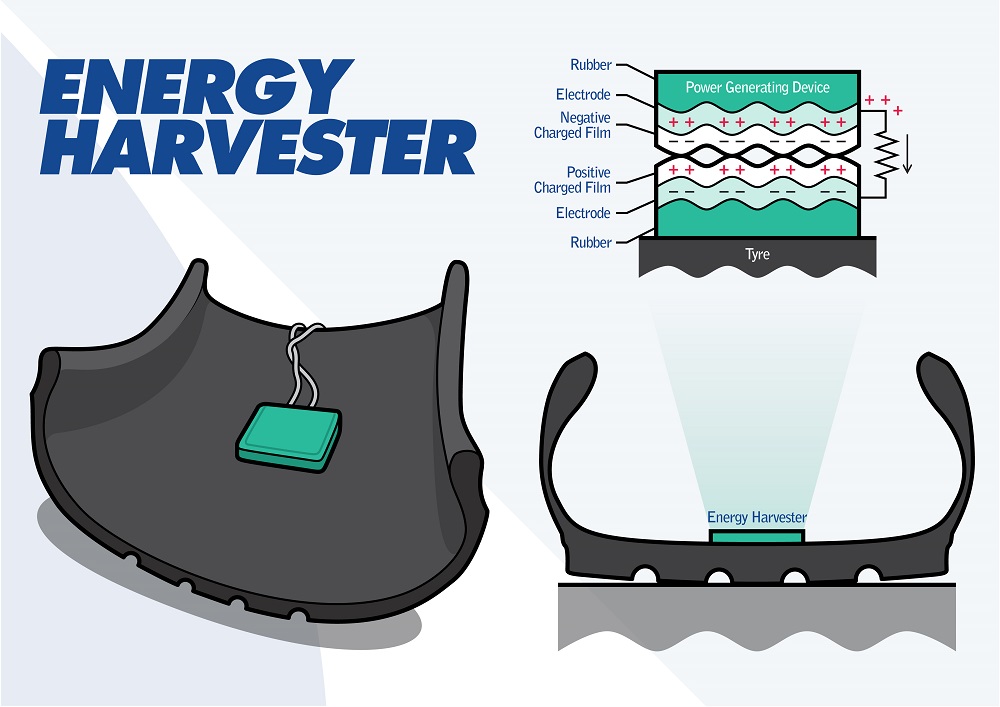

Sumitomo Rubber Industries, together with Professor Hiroshi Tani of Kansai University, have developed the ‘Energy Harvester’ that takes advantage of the build-up of static electricity. Known as ‘frictional charging’, it can produce power efficiently as the tyre turns. However, where the dynamo used a magnet and coil to generate electricity, the Energy Harvester has a much more sophisticated approach.

Inside are two layers of rubber each covered in an electrode, along with a negatively-charged film that interfaces with a positively-charged film. When fixed to the inside of a conventional tyre carcass, it generates electricity as the tyre deforms during each rotation.

Eliminate reliance on car’s battery

The engineers believe the Energy Harvester could lead to practical applications as a power source for sensors used in Tyre Pressure Monitoring Systems and other small automotive devices without drawing on electricity from the vehicle’s battery or electrical system.

The Energy Harvester is being developed as part of Sumitomo’s R&D programme to come up with technologies that target improvements in safety and environmental performance. The research project has now been selected by the Japan Science and Technology Agency as a Type FS Seed Project under A-STEP (Adaptable and Seamless Technology Transfer Program through Target-Driven R&D). Sumitomo Rubber Industries will now advance this research with support from the Japan Science and Technology Agency.