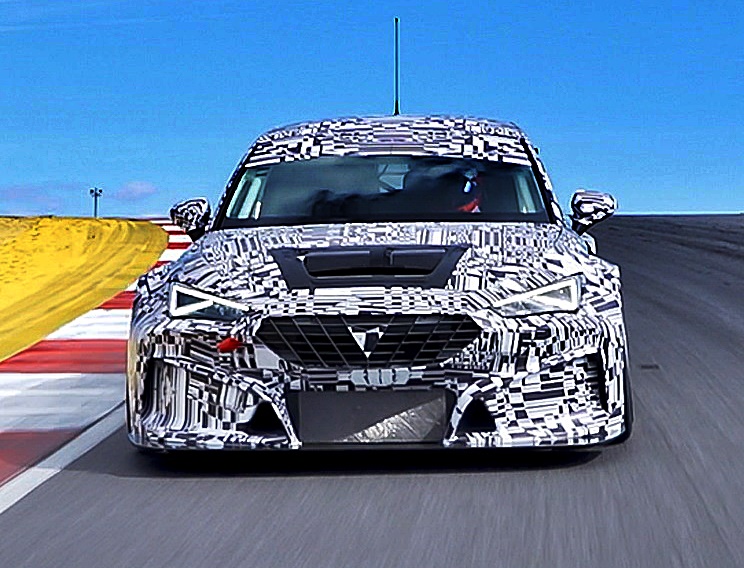

Audi Sport has unveiled the second generation of its successful RS 3 LMS model, with a season of testing ahead before going into production and being ready for customers at the end of 2021. The second generation of the entry-level touring car has been improved in many areas to offer more benefit to customers.

The RS 3 LMS, which has been available since the end of 2016, has made 3,105 appearances in a total of 1,051 races around the world to date. On average, there were almost three RS 3 LMS cars on the grid in each race. This is impressive considering that Audi has not been directly involved, with the exception of a 2-year program in the FIA WTCR in 2018 and 2019.

In the four years since its launch, the racing car has collected a total of 764 podium places in Africa, North and South America, Asia, Australia and Europe, including 279 overall wins. This is a win rate of 26.5% in an extremely tough competition in which TCR race cars from up to 14 manufacturers compete. It was considered the global ‘TCR Model of the Year’ in 2018.

More racing character

The second generation presents itself with new developments in all areas that serve two goals: To make the near-production entry-level even better and to optimize customer benefits in all areas. Despite this, the model remains inexpensive to buy and maintain, offers an even higher level of safety and, with up to 340 bhp available.

Visually, the second generation differs significantly from its predecessor. At 1.95 metres, it still meets the maximum width defined in the regulations, but the body extensions are integrated into the contours in a more harmonious and aerodynamically favorable way than before. The front apron incorporates the air intakes as part of a significantly revised cooling concept for the engine and brakes. The rear wing, suspended from the rear for the first time, completes the optimized aerodynamics of the TCR racing car.

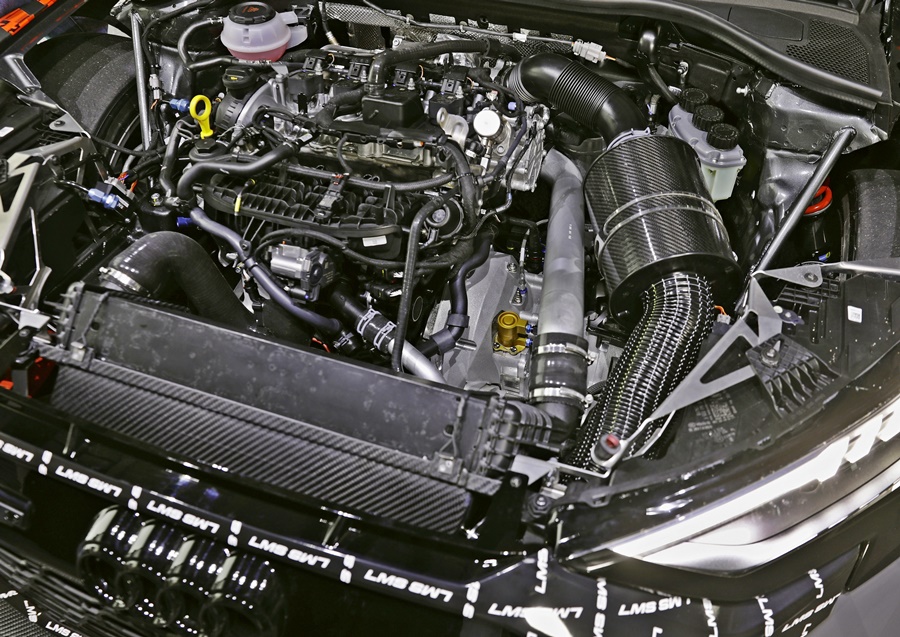

New engine generation

For the new RS 3 LMS, the fourth generation of the 2-litre 4-cylinder EA888 engine replaces the predecessor series. The engine block and cylinder head, crank drive, valve train, intake manifold, fuel injection and the new turbocharger remain absolutely standard in the racing car. Only the valve cover breather with its oil separator differs from the standard component, as does the exhaust system. Also, the standard engine management system from Magneti Marelli specified by the regulations is new.

The adoption of the engine from volume production has proved highly successful in TCR racing. In many cases, Audi’s power units already achieved tens of thousands of racing kilometres in the previous generation in the hands of the customers. Together with the standardized hardware, this guarantees transparency and equal opportunities for all manufacturers.

Benchmarks in safety

No other TCR touring car offers as many optional safety components as are on board as standard in the RS 3 LMS. The roll-cage consists of steel tubes that add up to just under 25.8 metres in length. A 6-point safety belt serves as restraint system for the driver.

The Audi Sport Protection Seat, unique in the TCR class, with its robust construction and elaborate upholstery offers maximum accident safety. For better occupant protection in the event of a side impact, it is moved closer toward the centre of the car. Optionally available seat-wrapping safety nets on the right and left provide additional protection for the driver.

The standard roof hatch facilitates recovery of the driver after accidents. It allows the helmet to be gently removed upward and, if necessary, a rescue corset (Kendrick Extrication Device) to be inserted vertically from above to stabilize the driver’s spine.

For the first time, the rear window in every car is made of polycarbonate ex factory at no extra charge. This material reduces weight and is extremely impact-resistant. The safety fuel tank complies with FIA FT3 regulations and has a capacity of 100 litres. A fire extinguishing system completes the safety equipment.

Improved ergonomics in the cockpit

The cockpit is even more driver-oriented and easier to operate. The steering wheel features a control panel specified for TCR purposes. In the centre console, 12 functions are ergonomically optimized and logically grouped in a clearly arranged keypad. The ignition and various light functions can be activated there, as can the cockpit fan or the optional windshield heating. The brake balance and, if necessary, the fire extinguishing function are also within easy reach below the centre console.

Adaptable chassis

The McPherson design on the front axle makes it possible to implement changes to the kinematics faster than ever before. Whereas the previous bolting system always required a chassis measurement for changes, spacer components known as shims can now be inserted in the control arm and track rod in a matter of minutes. The track rods are standard on the 4-link rear axle to achieve bump steer effects. They support the agility of the car when turning in.

“Our new Audi RS 3 LMS thus takes on a great and responsible legacy,” says Chris Reinke, Head of Audi Sport customer racing. “The focus of our development goals for our latest model was on the customers. Whether it’s about running times or setup options, safety or cockpit ergonomics: we want to offer the teams a car that’s even more of a racing car than before, that has many practical advantages in everyday use and that can be operated economically thanks to long running times.”