While most carmakers have formed alliances and even merged to face the new challenges of the 21st century, Honda has often chosen to proceed alone with its own resources. It has collaborated with other carmakers from time to time in specific areas, and often, it has been other manufacturers wanting to have access to Honda’s technology or products.

However, with the electrification of the industry which has a degree of urgency (with targets set for the end of this decade), even independent-minded Honda has seen it more practical to have closer working relationships with other carmakers. Other Japanese companies have already formed their own collaborative groups – Nissan and Mitsubishi in the alliance with Renault, and Toyota having joint programs with Mazda, Subaru, Suzuki and of course, Daihatsu and Hino which are within its own group.

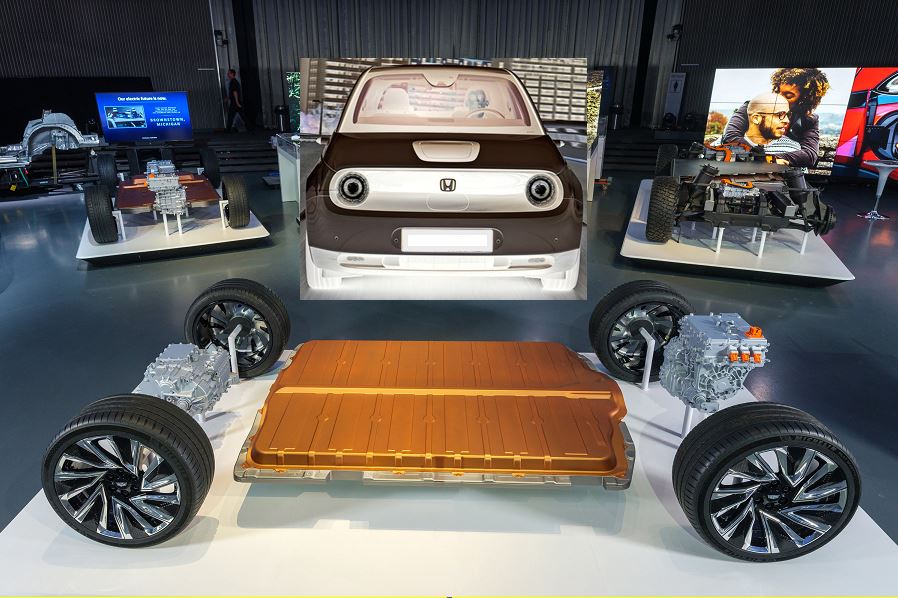

With an eye on the US market, Honda has chosen to expand its relationship with General Motors to co-develop a series of affordable electric vehicles. This follows on from the 2020 announcement to jointly develop two all-new electric vehicles for Honda, based on GM’s flexible global EV platform powered by proprietary Ultium batteries. The EVs will be manufactured at GM plants in North America with sales expected to begin in the 2024 model year in North America.

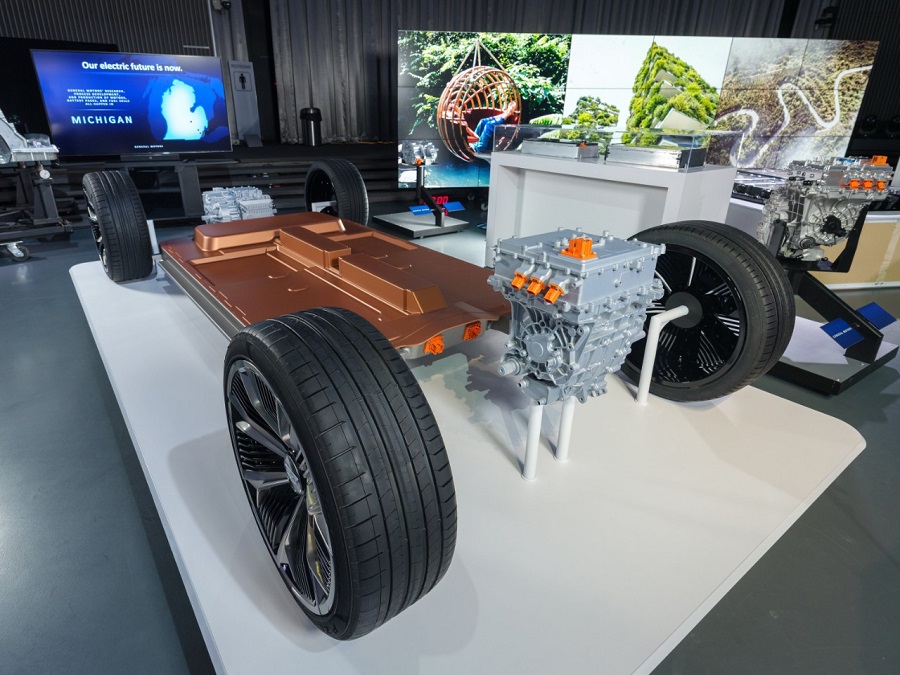

For this new joint venture, the EVs will be based on a new global architecture using GM’s next-generation Ultium battery technology. GM’s Ultium batteries are unique in the industry because the large-format, pouch-style cells can be stacked vertically or horizontally inside the battery pack. This allows engineers to optimize battery energy storage and layout for each vehicle design. The cells use a proprietary low cobalt chemistry and ongoing technological and manufacturing breakthroughs will drive costs even lower.

Ultium energy options range from 50 to 200 kWh, which could enable a GM-estimated range up to 640 kms or more on a full. Motors designed in-house will support front-wheel drive, rear-wheel drive, all-wheel drive and even performance all-wheel drive applications.

A joint statement says that there will be ‘global production of millions of EVs starting in 2027’ and these will include compact crossover vehicles which today account for the largest segment in the world, with annual volumes of more than 13 million vehicles.

Both companies will contribute their technology and design expertise as well as sourcing strategies. By standardizing equipment, it is expected that world-class quality, higher throughput and greater affordability can be achieved. A flexible, modular approach to EV development is expected to enable significant economies of scale for lower production costs.

“Honda is committed to reaching our goal of carbon neutrality on a global basis by 2050, which requires driving down the cost of electric vehicles to make EV ownership possible for the greatest number of customers,” said Toshihiro Mibe, Honda’s President & CEO. “Honda and GM will build on our successful technology collaboration to help achieve a dramatic expansion in the sales of electric vehicles.”

“The progress we have made with GM since we announced the EV battery development collaboration in 2018, followed by co-development of electric vehicles including the Honda Prologue, has demonstrated the win-win relationship that can create new value for our customers,” added Shinji Aoyama, Senior Managing Executive Officer at Honda. “This new series of affordable EVs will build on this relationship by leveraging our strength in the development and production of high quality, compact class vehicles.”

Earlier projects involving the two carmakers have focused on electric and autonomous vehicle technologies. In 2013, the two companies began working together on the co-development of a next-generation fuel cell system and hydrogen storage technologies. In 2018, Honda joined GM’s EV battery module development efforts.

They also have an ongoing relationship with Cruise and are working together on the development of the Cruise Origin, one of the first purpose-built fully autonomous vehicles designed for driverless ride-hail and delivery. The Cruise project, which involves Microsoft, is part of Honda’s new mobility business in Japan.

GM and Honda will also discuss future EV battery technology collaboration opportunities, to further drive down the cost of electrification, improve performance and drive sustainability for future vehicles. GM is already working to accelerate new technologies like lithium-metal, silicon and solid-state batteries, along with production methods that can quickly be used to improve and update battery cell manufacturing processes. Honda is making progress on its all-solid-state battery technology which the company sees as the core element of future EVs.

“GM and Honda will share our best technology, design and manufacturing strategies to deliver affordable and desirable EVs on a global scale, including our key markets in North America, South America and China,” said Mary Barra, GM Chair & CEO. “This is a key step to deliver on our commitment to achieve carbon neutrality in our global products and operations by 2040 and eliminate tailpipe emissions from light duty vehicles in the USA by 2035. By working together, we’ll put people all over the world into EVs faster than either company could achieve on its own.”

Honda will stop selling models with combustion engines from 2040, range to be fully electric