After the Taycan, the next all-electric sportscar from Porsche will be the Macan. Developed with the usual secrecy, prototypes have been running around the proving grounds of the Porsche Development Centre and the next step is to take them into the outside world for road-testing.

Real-world testing on public roads and in a real-life environment are important stages in the development of a new model. In the case of the electric Macan, due to be launched in 2023, the testing will cover at least 3 million kms worldwide in varying conditions. This will add on to the experience gained from countless previous test kilometres – driven in a virtual space.

Digital development preserves resources

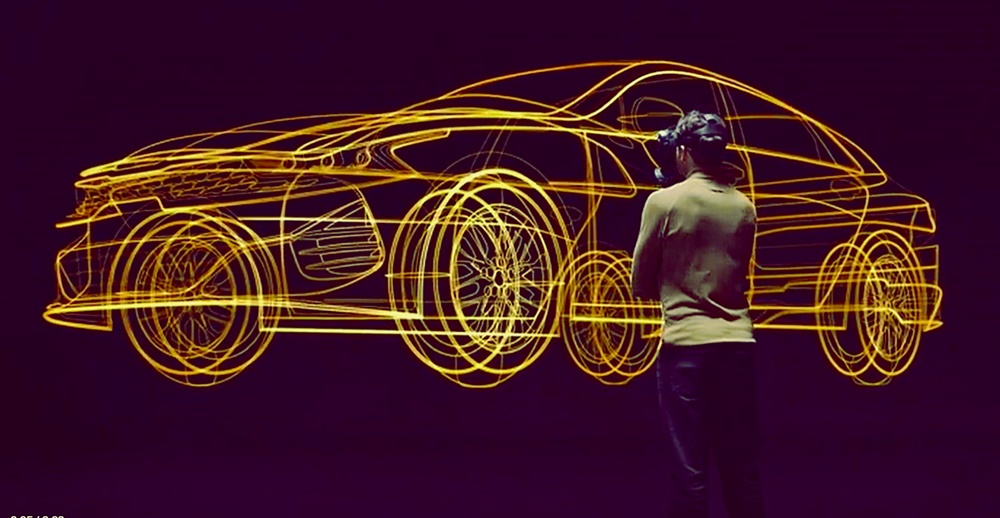

Digital development and testing not only saves time and costs but also preserves resources, so it enhances sustainability. Instead of real vehicles, the engineers use digital prototypes – computational models that replicate the properties, systems and power units of a vehicle to a high degree of accuracy.

There are 20 digital prototypes for the purpose of simulation in a number of development categories, such as aerodynamics, energy management, operation and acoustics. “We regularly collate the data from the various departments and use it to build up a complete, virtual vehicle that is as detailed as possible,” explained Andreas Huber, manager for digital prototypes at Porsche. This allows previously undiscovered design conflicts to be swiftly identified and resolved.

The aerodynamics specialists are among the first engineers to work with a digital prototype. “We started with a flow-around model when the project first started about 4 years ago,” explained Thomas Wiegand, Director of aerodynamics development.

Low aerodynamic drag is fundamental to the all-electric Macan with a view to ensuring a long range. Even minor flow enhancements can make a huge difference. The engineers are currently using simulations to fine-tune details such as the cooling air ducts. The calculations not only take into account different arrangements of the components, but they also reflect real-life temperature differences.

Virtual testing

New methods now allow very precise simulation of both aerodynamics and thermodynamics. “The digital world is indispensable to the development of the all-electric Macan,” said Wiegand. ”The electric drive system – from the battery through to the motor – requires a completely separate cooling and temperature control concept, one that is very different from that of a conventionally powered vehicle.”

While a temperature window of 90 to 120 degrees is the target for combustion engines, the electric motor, powertrain electronics and high-voltage battery require a range of between 20 and 70 degrees, depending on the component. The critical scenarios don’t occur on the road but can occur during fast high-power charging at high outside temperatures. However, the Porsche developers are able to precisely calculate and digitally optimise position, flow and temperature.

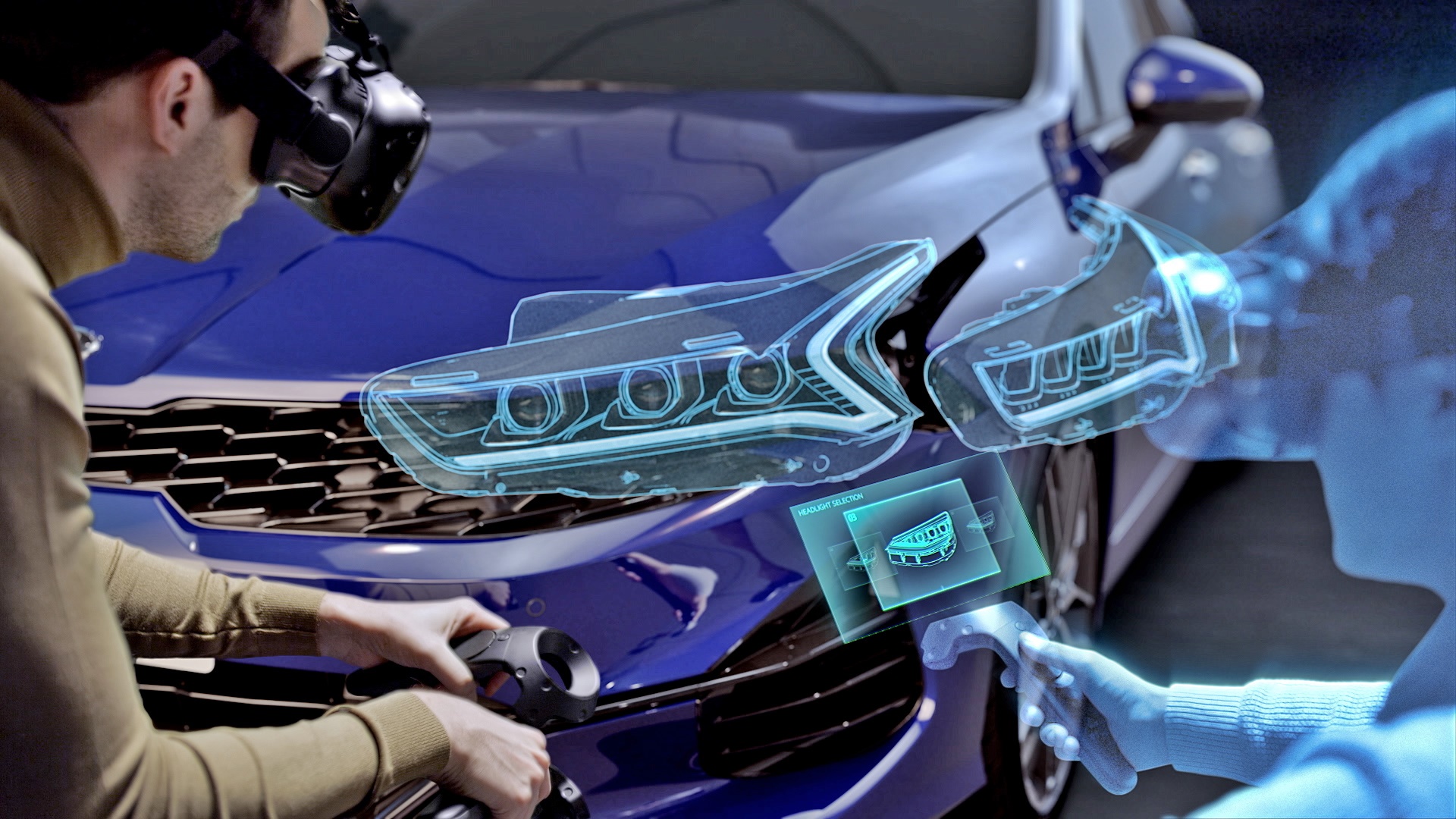

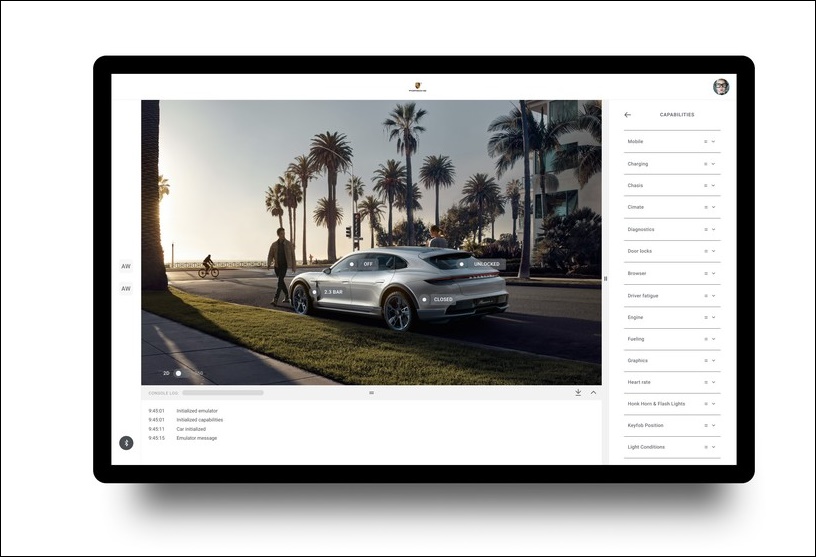

Virtual prototypes can be combined with real-world scenarios at an early stage. The best example here is the development of a completely new display and operating concept for the next generation of Macan. Using what is known as a seat box to recreate the driver’s environment, the display and operating concept can be brought to life in an early development phase in conjunction with the digital prototype.

“Simulation allows us to assess displays, operating procedures and the changing influences during a journey from the driver’s point of view,” explained Fabian Klausmann of the Driver Experience development department. “Here, the ‘test drivers’ are not just the specialists themselves but also non-experts. This allows all interaction between driver and vehicle to be studied down to the last detail, enabling selective optimisation even before the first physical cockpit has been built.”

To be the sportiest model in the segment

The first physical prototypes of the electric Macan were built using data obtained from the simulations – in some cases elaborately by hand or using special tools. These are then regularly adapted based on the virtual refinement process. By the same token, the findings from road testing are fed directly into digital development.

“Endurance testing on closed-off testing facilities and public roads in real-life conditions is still indispensable to ensure that the vehicle structure, operational stability and reliability of hardware, software and all functions meet our high quality standards,” said Member of the Executive Board Michael Steiner.

The demanding test programme for the electric Macan, carried out under the extremes of climatic and topographical conditions, includes disciplines such as the charging and conditioning of the high-voltage battery, which has to meet very rigorous standards.

“Like the Taycan, the all-electric Macan, with its 800-volt architecture, will offer typical Porsche E-Performance,” promised Steiner, citing development goals such as long-distance range, high-performance fast charging and reproducible best-in-class performance figures.

Combustion engine will still be offered

While Europe is accelerating into the era of pure electromobility with all-electric vehicles, Porsche understands that the pace of change will vary considerably across the world. In some regions, there will still be demand for vehicles with conventional combustion engines. Therefore, the next Macan will continue to have a variant with a combustion engine for markets which want it.

Entry-level Porsche Taycan available from March, priced from RM605,000