Volkswagen has been rolling out is all-electric ID. range of vehicles but by 2026 – that’s just 5 years away – the carmaker will go further with its electric vehicles. This will be the outcome of Project Trinity which will see an electrically powered sedan that will set new standards in terms of range, charging speed and digitisation. It will also have autonomous driving capabilities higher than what is currently available.

The project name ‘Trinity’ is derived from the Latin ‘trinita’ and stands for the ‘tri-unity’. Accordingly, Trinity stands for three crucial themes: a newly developed electronics platform with state-of-the-art software, the simplification of the supply structure, and fully networked and intelligent production at the main plant in Wolfsburg, Germany.

“Trinity is a sort of crystallisation point for our ACCELERATE strategy, a lighthouse project, our software dream car,” said Ralf Brandstatter, CEO of the Volkswagen brand. “The newly developed vehicle architecture will set standards in terms of range, charging speed – charging as fast as refuelling – and digitalisation.”

Greater autonomy, less driver involvement

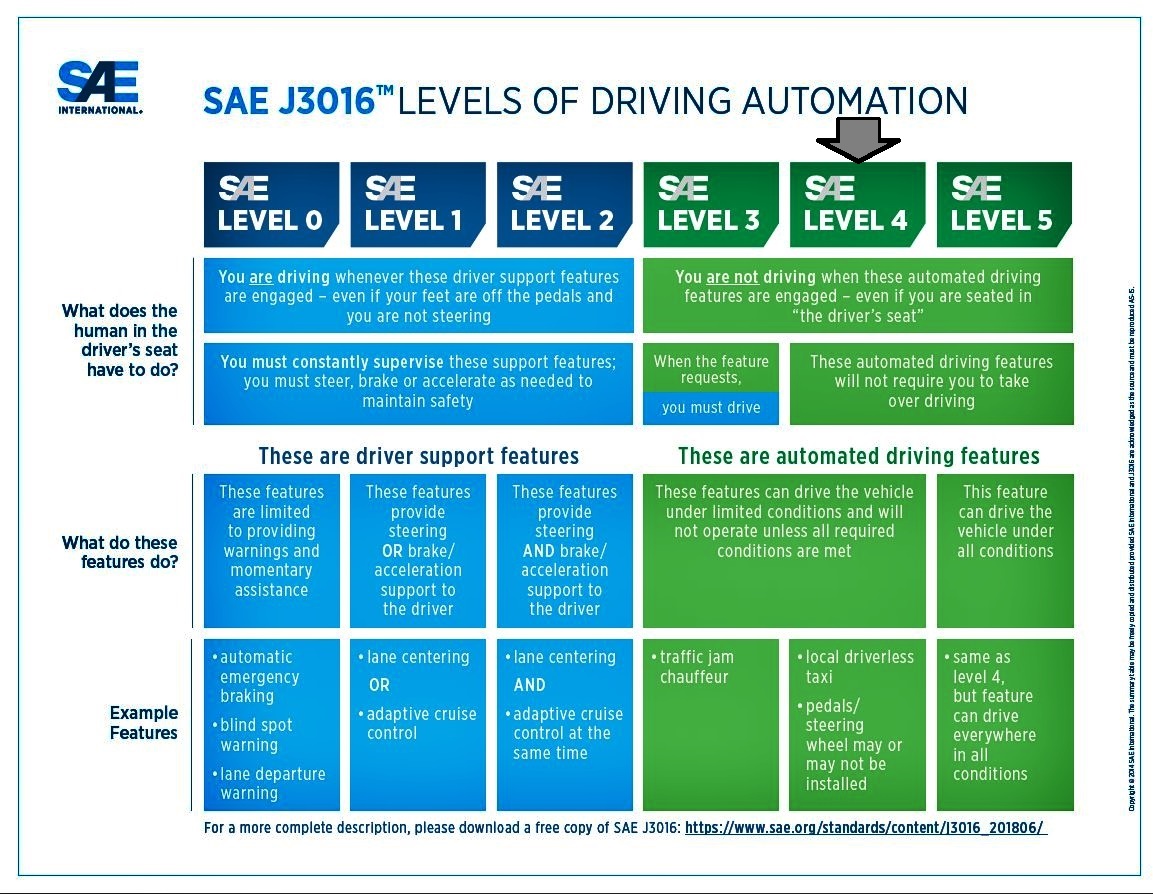

In addition, Trinity will make autonomous driving in the volume segment possible for many people. By the planned start of volume production in 2026, Trinity will already reach Level 2+ and be technically ready for Level 4. With this level, human interaction is not required so the driver does not have to maintain a view of the road ahead or surroundings. It is expected that the artificial intelligence will be advanced enough to assess more complex situations, and take action to avoid an accident. This is already available now with Automatic Emergency Braking but the driver still needs to give attention.

Autonomous driving for more people

“We are using our economies of scale to make autonomous driving available to many people and to build a learning neural network. In this way, we are creating the conditions for the continuous exchange of data from our vehicle fleet – for example, on the traffic situation, on obstacles or on accidents,” said Mr. Brandstatter. “Trinity thus gives people time and saves them stress. After a long highway trip, you arrive at your destination relaxed – because you have been driven by a ‘chauffeur’ to your vacation or to your home after work. Trinity therefore becomes a kind of ‘time machine’ for our customers.”

With the production of the new model, the Wolfsburg plant will become a showcase for state-of-the-art, intelligent and fully networked production processes. “We will completely rethink the way we build cars and introduce revolutionary approaches. Digitalisation, automation and lightweight construction play an important role here,” added Mr. Brandstatter.

Future vehicle models such as Trinity will be produced with considerably fewer variants, and the hardware will be largely standardised. The cars will then have virtually everything on board and customers will be able to activate desired functions ‘on demand’ at any time via the digital ecosystem in the car. This will significantly reduce complexity in production.

New business models

By developing the automobile into a software-based product, Volkswagen is creating the conditions for new, data-based business models. Entry barriers to individual mobility are to be lowered while, at the same time, offering even more attractive usage packages.

Volkswagen intends to generate additional revenue in the usage phase – for charging and energy services, for software-based functions that customers can book as needed, or for automated driving. “In the future, the individual configuration of the vehicle will no longer be determined by the hardware at the time of purchase. Instead, customers will be able to add functions on demand at any time via the digital ecosystem in the car,” Mr. Brandstatter predicts.