Today, Mercedes-Benz has a range of compact models in its range but this was not the case before 1997 when the smallest model was the C-Class W201 (known as 190 E earlier). However, the German carmaker did plan to have a car smaller than the C-Class and had been thinking about it on and off from the early 1980s.

While the world was excited at seeing the completely new ‘baby Benz’ in 1982, a small group of engineers was busy preparing a presentation for a model that was even smaller. It was a ‘city car’ concept which would have front-wheel-drive, two seats, sliding doors and large windows for an optimum all-round view.

Many believe this to be the starting point for the first A-Class and the idea of a mini vehicle had stimulated the designers to think of new approaches. However, that proposal never went very far as it was not easy to meet the high safety standards that must be in every vehicle with the Stuttgart Star. The technology available then made it almost impossible to design a car so small which could provide high levels of impact protection.

So the idea of a small Mercedes-Benz stayed in the background, the subject of occasional discussions and ongoing research. Nevertheless, it was clear that customers – even those who bought Mercedes-Benz cars – wanted more practical cars as driving conditions in urban areas became more congested. While they appreciated the comfort afforded by a large sedan, they also liked having something small and maneuverable for city use. But it had to also have the safety they had come to expect from a Mercedes-Benz.

Traffic studies conducted in Greater Berlin came to similar conclusions: the time was ripe for an innovative, extremely compact automobile taking up less space on the road, consuming less fuel and producing lower exhaust emissions. But the objectives and customer demands that had been defined could not possibly be met by a conventional sub-compact car design.

It was time for a rethink as there were still conflicts of aims which had to be overcome. Specifically, how to design a car with small exterior dimensions, but the interior space of a medium-size sedan? How should you design a car that is suitable for different propulsion systems (electric powertrains were also considered)? How can the company’s stringent internal safety regulations be met with a small bodyshell? In other words: new ideas were needed for an entirely new class of car.

The sandwich design

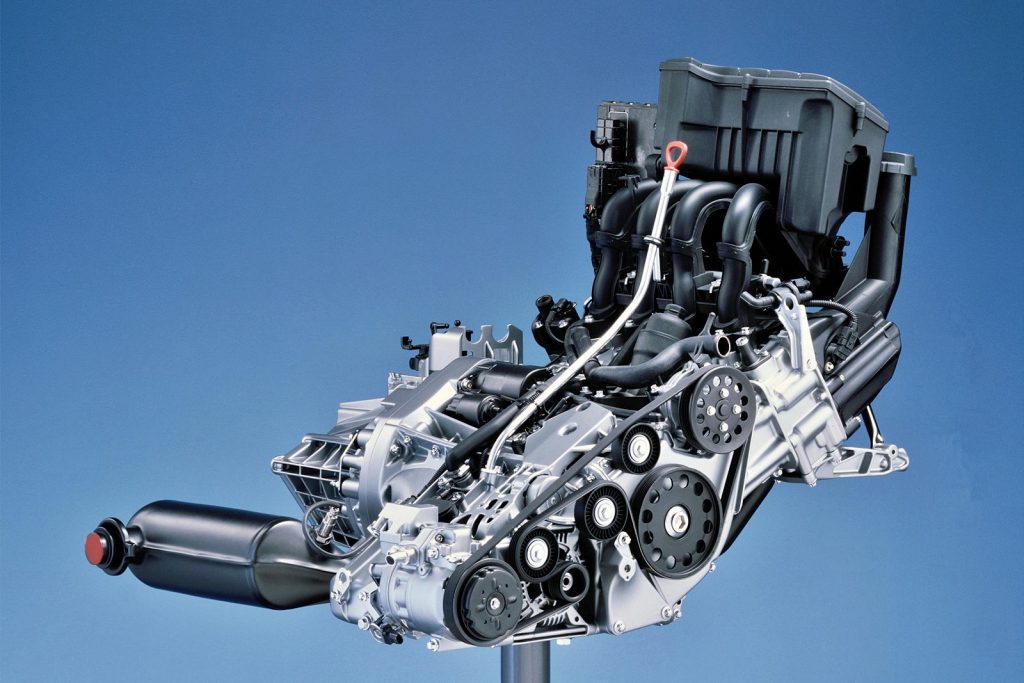

All the criteria were collated in a matrix and evaluated. A new design was available for a conventional front-wheel drive system with the novel principle of a drive unit accommodated in a sloping position – partly in front of, partly underneath the passenger cell – so that in a crash, it would dip downwards, thus not presenting a danger to the car occupants.

Since the bodyshell was divided into two horizontal levels, this invention was called the ‘sandwich design’. This was in contrast to a conventional design in which the passenger cell sits in a low-set pan with structural members at the front and rear. The sandwich design instead had members going straight through from the bumper to the tail. The passengers were positioned above the member construction and were thus protected against impact.

This offered advantages in a crash – while conventional body systems employ special structural member designs to conduct the impact forces around the passenger cell, this complex ‘bypassing’ of the passengers was no longer necessary. The straight longitudinal members absorbed the forces of the crash in a single plane below the passenger cell, dissipating the forces at a high level of efficiency.

Birth of the project

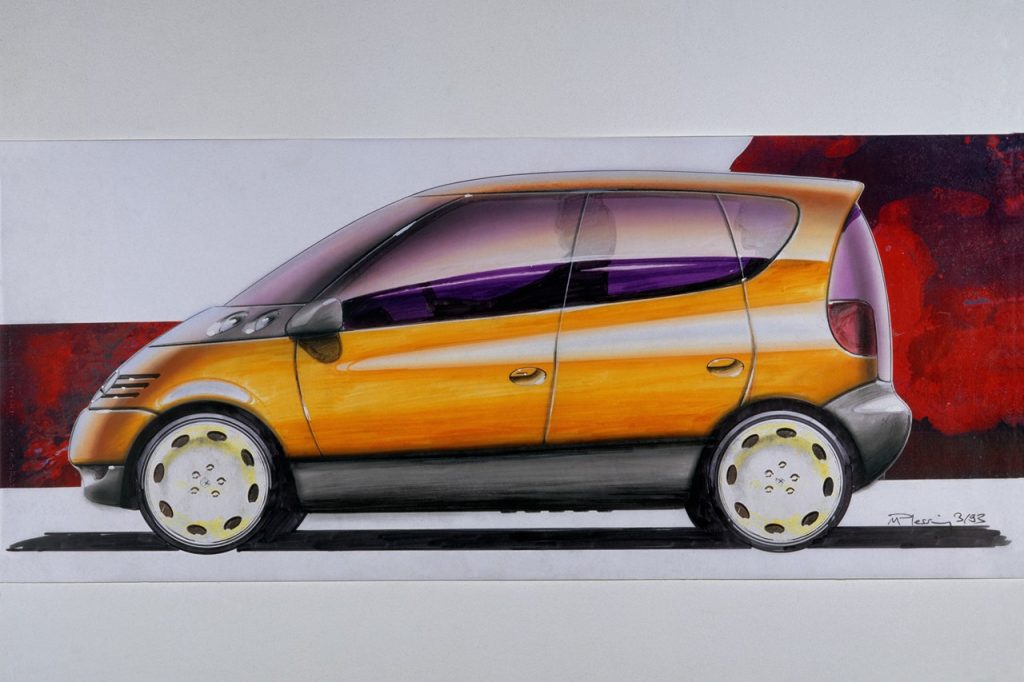

The invention of the sandwich design then provided the impetus in November 1991 for the implementation of a second project in the form of a basic study. This was the Study A, the direct predecessor to the original A-class. Two driveable prototypes were to be built – one electric-powered, one with an internal combustion engine. The Mercedes-Benz board wanted to present them to the public at the 1993 Frankfurt International Motorshow, so the time-frame for development was less than 24 months.

But then came a different turn of events. At the presentation of the design in June 1992, there was already a plan for large-scale production. A work team began recording all criteria for a possible production model in skeleton specifications. It was a departure from the usual process of first having a pre-development phase of roughly 2 years. But the project team was so enthusiastic and so convinced by the car and its design that they felt they could shorten the process.

From then on, the development program proceeded on two levels: a pre-development and design team took care of the models for the motorshow while, from January 1993, a project team began the development of the production model which would become the first A-Class.

Strong, positive public reaction

The Study A’s reception in Frankfurt, where it was presented as an experimental forerunner and idea-testing model for the A-class, vindicated the company’s decision to offer a compact car. The reaction of the press and the public was overwhelming. In response to the question whether Mercedes-Benz should build such a car, 90% of visitor answered ‘yes’. Some said it was the Mercedes-Benz they had been waiting for.

The carmaker also displayed the Study A at the Tokyo Motorshow the same year. There too, the response was positive though it was not surprising as that market has a dominance of small cars. A compact model with the Mercedes-Benz badge was certainly very appealing.

The motorshows provided many opportunities to fine-tune the design and concept. Customer opinion was also constantly the focus of attention during the A-class development phase. Regular customer interviews yielded new points and suggestions to be taken into consideration.

Taking into account the wishes of young families, for instance, the engineers lengthened the bodyshell to 3.57 metres (Study A was 3.35 metres), primarily leading to an enlargement of the boot. The result was that even when the back seats were occupied, the rear compartment of the A-class would have sufficient space to easily stow a pram.

New factory for new model

With no doubt about the good market prospects for a Mercedes-Benz model in this size class, development proceeded at speed. This also meant that a production site would have to be found quickly – one with sufficient capacity for production volumes of up to 200,000 cars per year. There was a choice of several sites in France, Britain and the Czech Republic, but the final decision went to the newly-built Mercedes-Benz plant in Rastatt, Germany.

Ten days before Christmas 1993, the designers invited the board, directors and project managers to a presentation of 5 prototypes. At the end of the event, which was held under the motto “One will be the winner”, the interior and exterior design of the new models was decided. The development team began the task of integrating systems and equipment to the new model which was due to roll off the production line 32 months later.

It was an ambitious target, given that the engineers had almost twice as many jobs to solve than is usual when developing a new car. This was because, with almost every new model, there would be a predecessor model from which some parts could be carried over (or modified slightly). The A-Class was an entirely new model line with no parts common to other models – except perhaps the Star.

One major milestone in the development was in optimizing the safety of the new body design. It was pioneering work; never before had a car as short as 3.57 metres had to meet such high safety standards, and no manufacturer had ever attempted to use a novel body design to compensate for the physical crash handicap which cars of this size have.

Real-world prototype testing

From April 1995, the first camouflaged prototypes were ready for testing in the real world. The engineers had already tested the new model’s systems on so-called component carriers which were similar in appearance to the Study A. A major prototype test was scheduled for September 7th 1995: the A-class versus E-class crash test. This was important to see how the smaller A-Class would perform in a vehicle-to-vehicle crash to test passenger, especially as it was a smaller car. Mercedes-Benz had never carried out such a test on a new model in its prototype stage before. The findings showed that the sandwich design fulfilled the engineers’ expectations.

As 64 prototypes were completing millions of test kilometres in different parts of the world, the factory was prepared for production which would commence in mid-1996. The 32-month program had been hectic but it heralded a new era for Mercedes-Benz in the compact class when the A-Class – model W168 – made its global debut at the 1997 Frankfurt Motorshow.