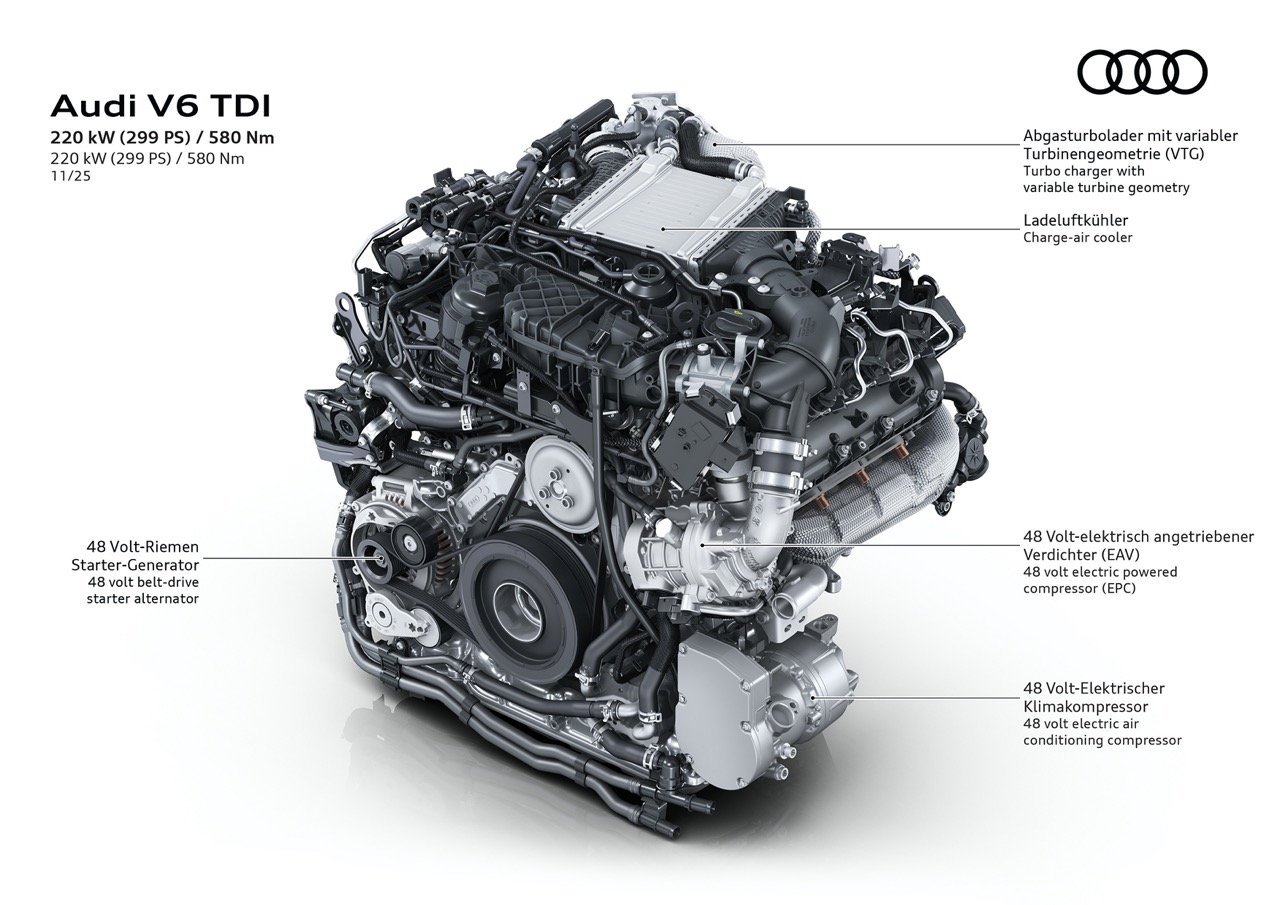

Audi has added a new three-litre V6 diesel engine to the Q5 and A6 ranges, producing 299 PS and 580 Nm of torque. This version of the engine marks the first time the brand has paired its MHEV plus system with an electrically powered compressor, creating a more responsive and efficient setup than previous diesel units. Orders for models equipped with the V6 TDI quattro are now open.

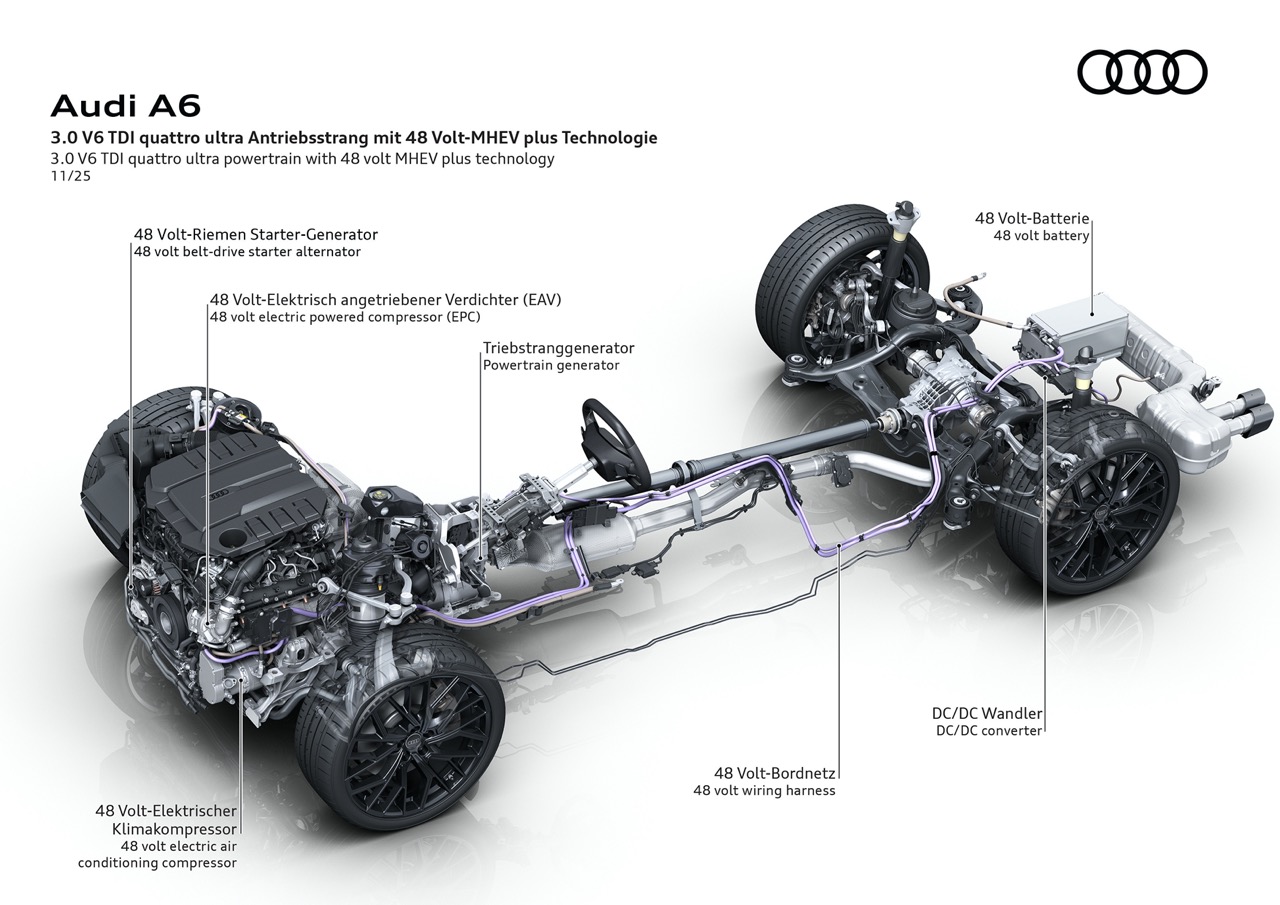

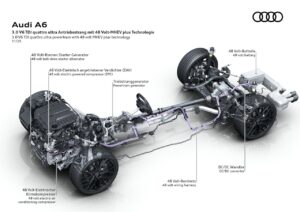

The MHEV plus system builds on Audi’s earlier mild-hybrid technology by bringing together a belt alternator starter, a powertrain generator and a lithium iron phosphate battery. The belt alternator starter starts the engine and supplies energy to the battery, while the powertrain generator enables short periods of fully electric driving in low-speed or steady-flow traffic.

It also delivers an additional 230 Nm of torque and up to 24 PS when setting off or overtaking, and it recovers up to 25 kW of energy when braking.

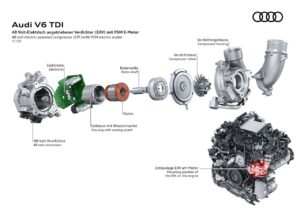

For the first time, Audi has paired this hybrid setup with an electrically powered compressor. This addition plays a key role in both the charging system and the engine’s combustion strategy. Working alongside the turbocharger in a two-stage system, it improves response at low engine speeds and helps balance strong performance with reduced fuel consumption. The combination of the new compressor, the belt alternator starter and the powertrain generator gives the V6 TDI strong acceleration whether starting from rest, joining faster traffic or cruising at higher speeds.

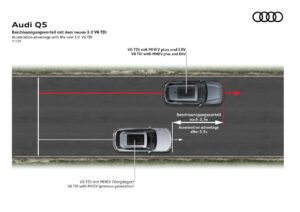

The electrically powered compressor addresses turbo lag by supplying immediate boost, allowing the engine to produce high torque even at low revs. Audi says the improved response is clear during the first moments of acceleration, with the car covering noticeably more distance in the same time than the earlier V6 TDI. As the engine increases its revs, the belt alternator starter provides support, the powertrain generator contributes torque and the compressor increases boost pressure almost instantly. Together, these elements create a more direct and confident driving feel.

Compared with earlier Audi models that used an electrically powered compressor, such as the S4 and SQ5, the latest version operates across the full engine speed range rather than within a narrow band. A redesigned airflow system and a more advanced permanent-magnet synchronous motor have widened its operating window and improved efficiency.

The compressor wheel can reach 90,000 rpm in around 250 milliseconds, almost 40 per cent faster than before, helping build the maximum boost pressure of 3.6 bar nearly a second quicker than the outgoing engine. Audi notes that the result is acceleration similar in immediacy to that of an electric motor.

The new V6 TDI is also compatible with HVO 100, a renewable diesel that meets European standard EN 15940 and is identified by an XTL label on the fuel cap. HVO, made from waste oils and by-products from the food and agriculture sectors, can reduce CO₂ emissions by 70 to 95 per cent compared with fossil diesel.

It can be blended with standard diesel or used on its own. Audi now fills new vehicles, leaving its Ingolstadt and Neckarsulm plants with HVO fuel, highlighting its move towards lower-carbon operation even before customer use.

With the introduction of its latest electrified diesel, Audi is aiming to deliver improved efficiency, stronger everyday performance and wider fuel flexibility—while keeping conventional engines relevant within a changing emissions landscape.