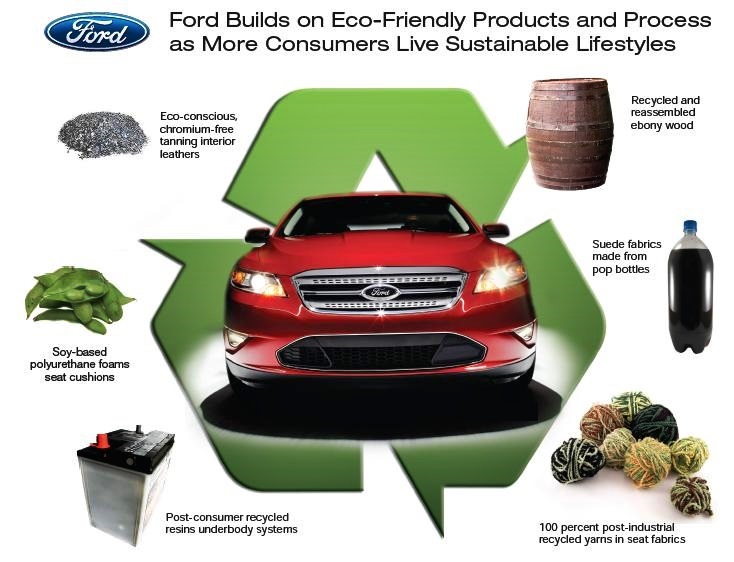

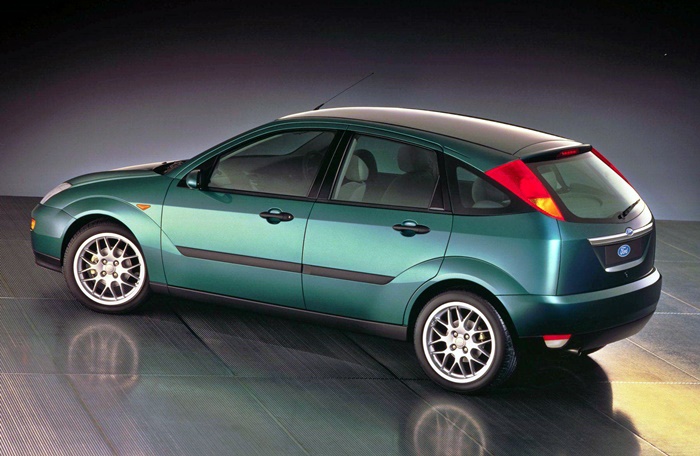

Ford Motor Company has long been making car parts from discarded materials that can be recycled. In one example, old jeans were used as sound insulation material for the first generation of the Focus. Besides plastic bottles, recycled resins are used for various other parts, supporting the company’s sustainability agenda.

Now, working with McDonald’s in the USA, coffee beans will also be used in vehicle parts such as headlamp housings. Every year, gigantic quantities of coffee chaff – the dried skin of the bean – naturally comes off during the roasting process. Together, Ford and McDonald’s can use a significant portion of that material rather than just throw it away.

The companies found that chaff can be converted into a durable material to reinforce certain vehicle parts. By heating the chaff to high temperatures under low oxygen, mixing it with plastic and other additives and turning it into pellets, the material can be formed into various shapes. . This is the first time Ford has used coffee bean skins to convert into selected vehicle parts.

The chaff composite meets the quality specifications for parts like headlamp housings and other interior and under-bonnet components. The resulting components can be about 20% lighter and require up to 25% less energy during the molding process. Heat properties of the chaff component are significantly better than the currently used material, according to Ford.

McDonald’s is expected to send a significant portion of its coffee chaff in North America to Ford to be incorporated into vehicle parts. This will help Ford as it progresses toward a goal of using recycled and renewable plastics in vehicles globally, with an increasing range of sustainable materials.

“McDonald’s commitment to innovation was impressive to us and matched our own forward-thinking vision and action for sustainability,” said Debbie Mielewski, Ford senior technical leader, sustainability and emerging materials research team. “This has been a priority for Ford for over 20 years, and this is an example of jump starting the closed-loop economy, where different industries work together and exchange materials that otherwise would be side or waste products.”

Planning to buy a Ford vehicle in Malaysia? Visit www.sdacford,com.my for the location of the nearest showroom.

Ford uses 1.2 billion plastic bottles for auto parts each year