“There’s no replacement for displacement’ used to be the belief in the auto world, especially among enthusiasts as well as those who sold or used commercial vehicles. Back in the days before turbocharging was widely used, getting more power from an engine meant making it bigger. A larger displacement allowed more air and more fuel in the combustion chamber, generating more power upon combustion.

That approach remained for decades, especially in America where fuel was cheap and drivers liked lots of power and torque. For the commercial vehicle sector, big engines were a must (and still are), for the high output needed to haul heavy loads. The higher compression ratios possible, resulting in higher pressures, produce more torque. And the more torque available, the better when it comes to carrying and moving heavy loads.

However, since the beginning of this century, environmental concerns have required manufacturers to address issues of fuel consumption and exhaust emissions. For petrol engines, downsizing has been a popular approach, coupled with technologies like direct injection and turbocharging which have even boosted output while making engines smaller (in displacement as well as size) and lighter.

For diesel engines, the initial solution was the introduction of commonrail fuel delivery system along with more advanced turbocharging. However, displacement remained big as there was still the matter of ‘no replacement for displacement’. While commonrail systems have raised outputs and made diesel engines more refined, large displacements have still be maintained which needed to be addressed.

Drawing on its very long experience specializing in diesel engines and developing them, Isuzu Motors naturally took on the challenge of developing a new generation of engines that would be in tune with the demands of the 21st century. Having developed a very wide range of engines with displacements of even more than 15 litres, Isuzu’s engineers had the knowledge and skills for the mission.

While the need to downsize the engines in the bigger commercial vehicles was not so urgent, there was a need to do so for the smaller range of engines used in pick-up trucks like the popular D-MAX. With pick-ups becoming increasingly used as an alternative to passenger cars for daily transportation, customers wanted more economical and efficient engines but still with the useful characteristics of the conventional turbodiesel engines.

The optimum size for today

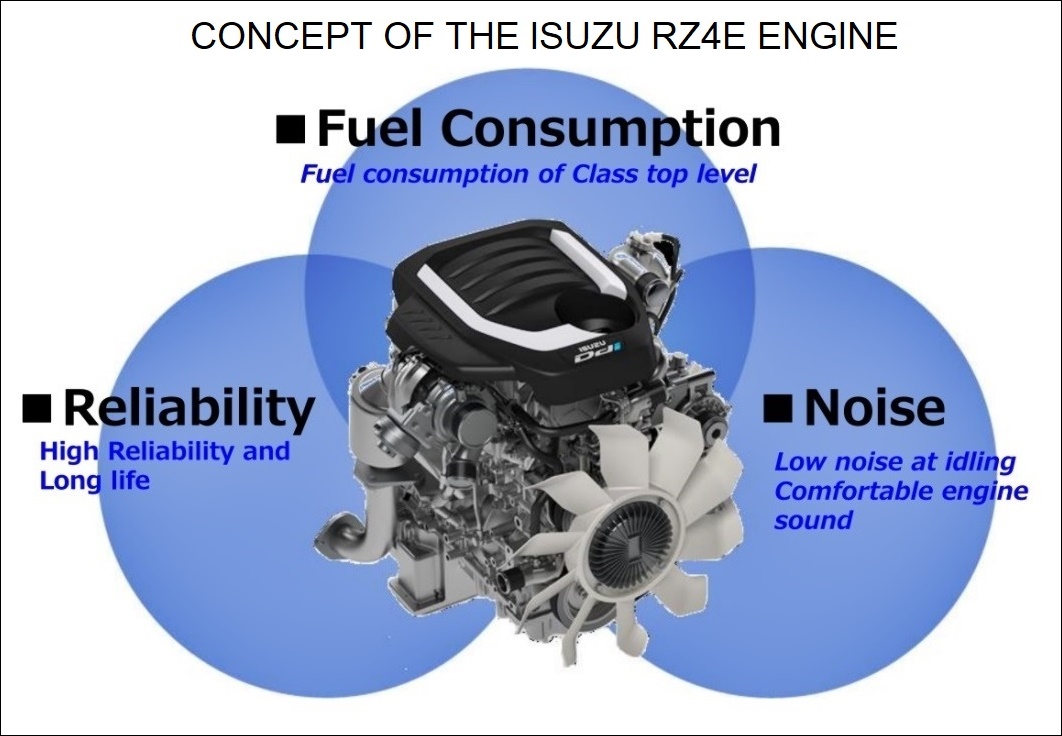

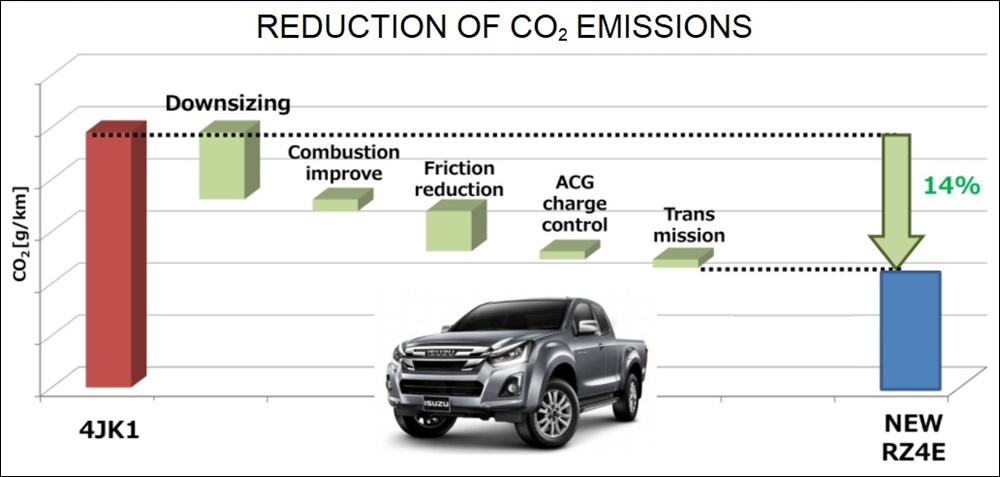

Besides Isuzu’s original analytical technology of diesel combustion, extensive research and simulations identified 1.9 litres as the optimum size for the 4-cylinder configuration common in pick-up trucks. This was the starting point for the all-new engine which would come to be designated ‘RZ4E’. Three clear objectives were pursued: a) Best-in-Class fuel consumption; b) High reliability for long life; and c) Low noise levels. Straightforward objectives but challenging to meet and the engineers drew on new technologies to achieve them.

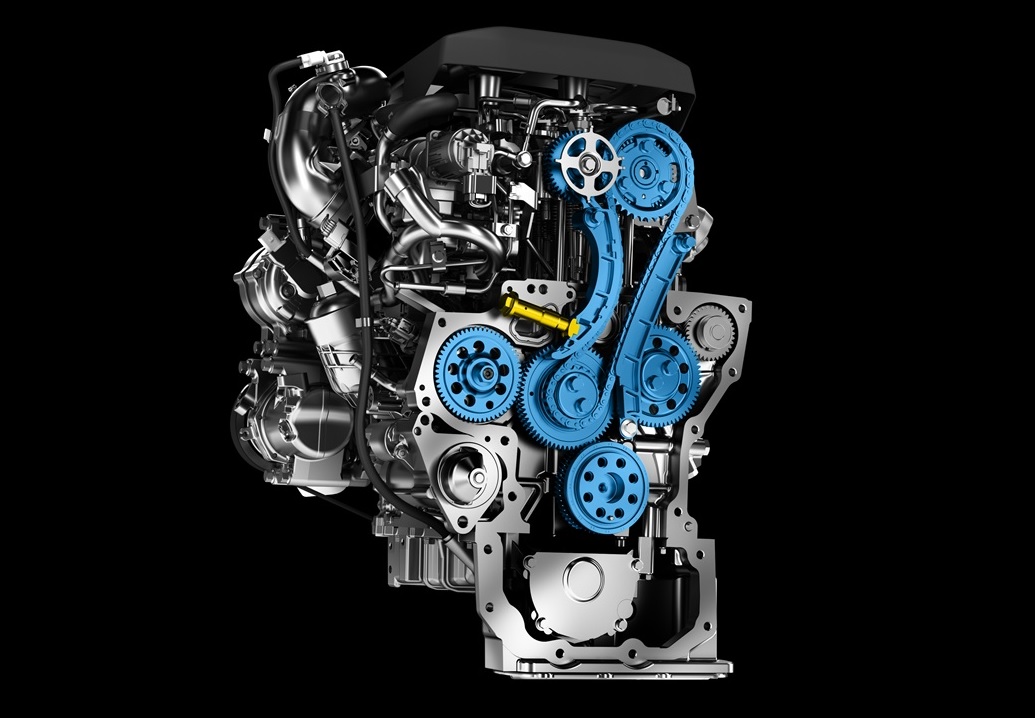

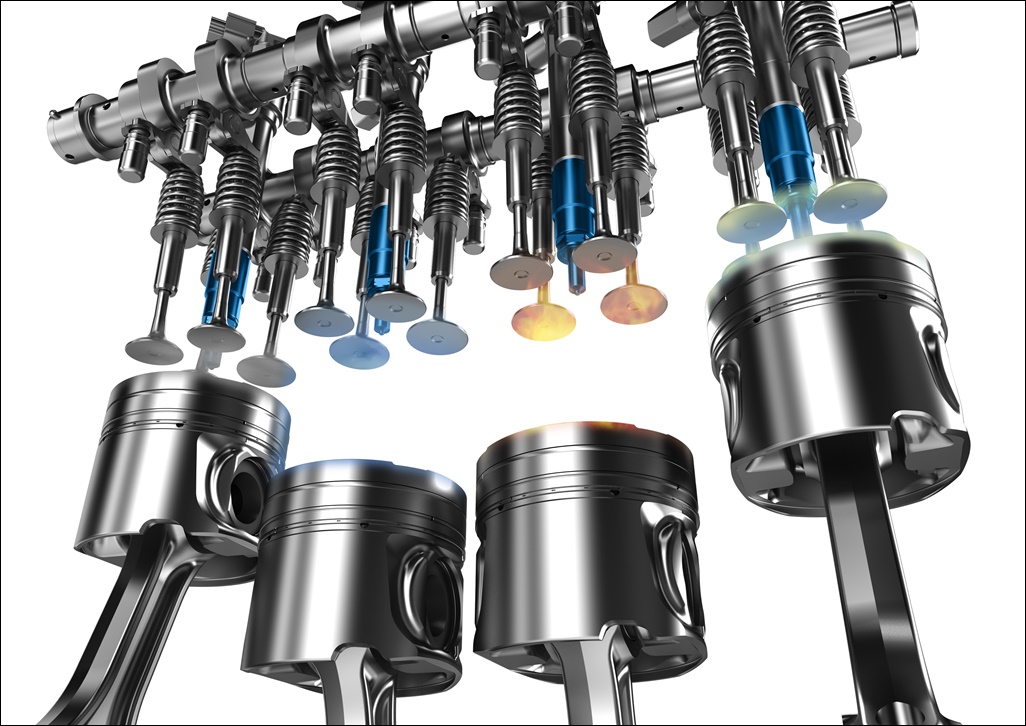

Downsizing the displacement would immediately result in lower weight, which is always a goal of engineers. Reducing internal friction – by as much as 37% – was also an important objective as less friction can improve power output. Computer-aided design of the pistons and combustion chambers also improved efficiency.

Along with optimised structural engineering and the use of better materials, the overall result was an engine that was not only more efficient but also surpassed the performance levels of bigger engines.

Less displacement but more output!

Compared to the 2.5-litre engine of the 4J series popularly used in the D-MAX before, the new RZ4E engine produces 110 kW of power at 3,600 rpm and 350 Nm of torque between 1,800 rpm and 2,600 rpm. These represent increases of 10% in power and 9.4% in torque – with a displacement that is 14% less. Notably, the improvement has not taken away the desirable characteristic of a diesel engine which is its flat torque curve.

Reliability is an important thing for Isuzu and is one of the reasons why its pick-up trucks are popular. Those who are in the commercial vehicle sector appreciate reliability and durability as they cannot afford to have a vehicle in the workshop frequently for repairs. The same also generally applies to any vehicle owner as everyone wants to enjoy using their vehicle as much as possible, and to keep cost of ownership low.

More reliable and durable

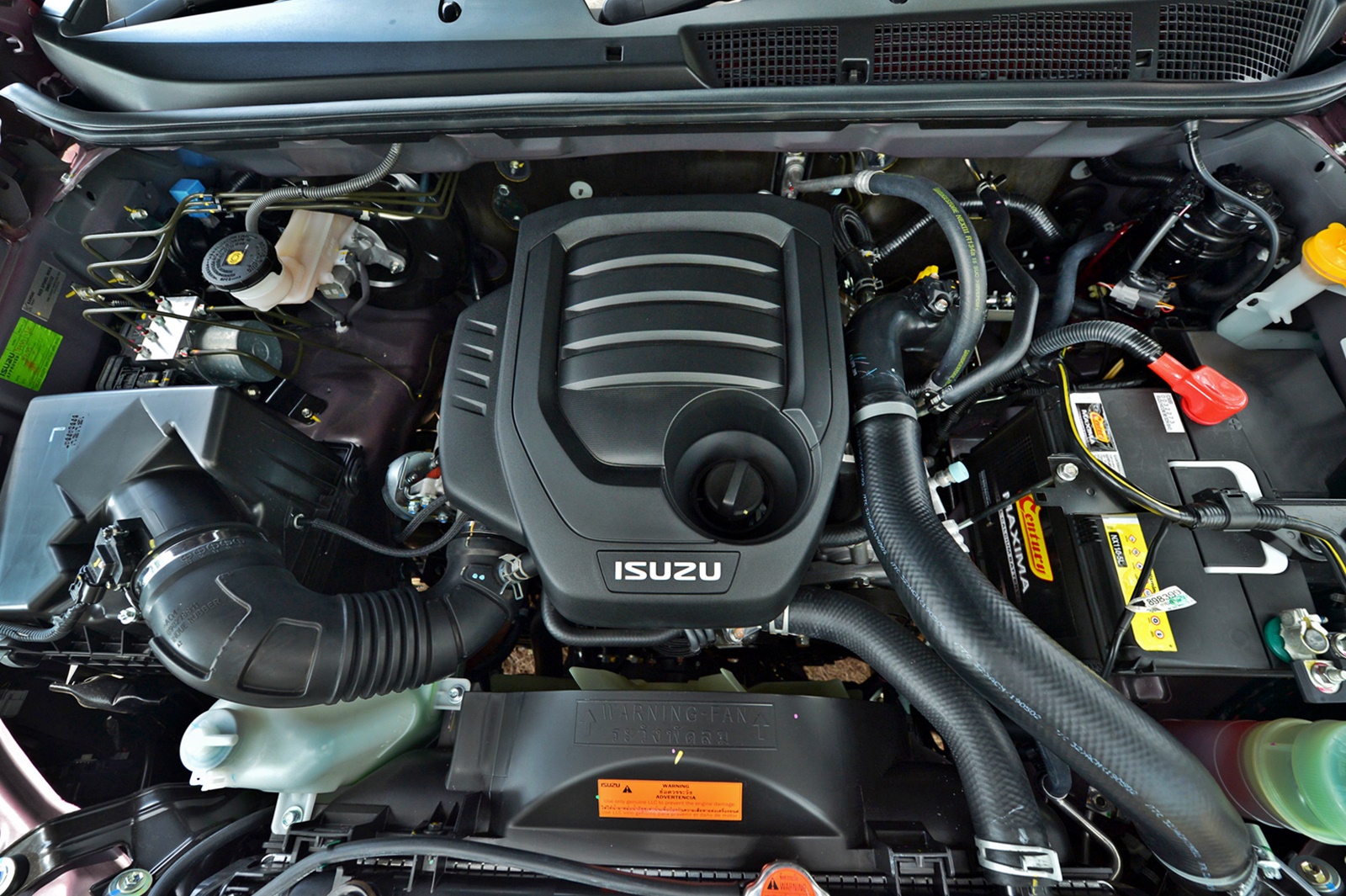

To improve the reliability aspects, the engineers installed Hydraulic Lash Adjusters (HLA) which automatically ensure that the valve lifters are always correctly adjusted. Likewise, the use of a serpentine belt also keeps the fanbelt correctly tensioned at all times. Incidentally, the timing chain is of steel for a long service life, another strong point of Isuzu engines.

Having a more advanced engine with higher output and higher efficiency would be wasted if that extra output could not be utilized fully. To ensure this, the engineers also developed a better transmission system with a new 6-speed manual transmission as well. The aim was to provide smoother and stronger takeoffs, especially on slopes, and this led to the development of the Vehicle Launch Assist Control. Basically, this feature manages engine output, raising torque levels at the time when the vehicle is starting off. The final gear ratio has also been revised to improve driveability and acceleration.

Tuned for Malaysian conditions

Isuzu sells its vehicles all over the world and different countries and regions have different regulations as well as fuel. To ensure that customers would be able to enjoy the maximum benefits of the new RZ4E engine, extensive testing is conducted before launch.

In the case of the Malaysian market, much of the testing focused on performance in high altitude areas and tuning the engine to run optimally on the lower quality fuel which today is Euro 2 B20 biodiesel. The studies led to the installation of a pre-fuel filter to ensure fuel cleanliness.

The attention to ensuring that the engine could meet all the conditions of the Malaysian market ensured that it could be introduced with confidence. Isuzu Malaysia would lead the market in bringing an innovative engine to Malaysian customers as no other manufacturer has offered a downsized turbodiesel engine with no compromise in performance and capabilities.

Certainly, it destroys the perception that there is ‘no replacement for displacement’! And where fuel efficiency is concerned, the D-MAX with the RZ4E engine is the first pick-up truck in Malaysia to qualify as an Energy Efficient Vehicle (EEV).

Proven in the Isuzu Dura Challenge

The 2020 Isuzu Dura Challenge proved the engineering supremacy of the new RZ4E ‘Blue Power’ engine. Isuzu Malaysia loaded a 1.9-litre D-MAX to its maximum permissible capacity of a ton and took it over some of the highest accessible hills along the Titiwangsa Mountain Range in Peninsular Malaysia.

In total, the vehicle clocked over 1,000 kms, with two bars of fuel still remaining in the tank. More significantly, the D-MAX with the Blue Power turbodiesel engine never had any difficulty in the high altitudes, even with such a heavy load on board.

Since its launch, the superiority of the Isuzu engine has been recognized by awards such as the Carlist ‘Diesel Engine of the Year (2019 & 2020)’ and it would certainly have been influential in the D-MAX being selected as ‘Pick-up Truck of the Year 2020′ (DSF).

The best way to experience this is to take a test-drive of the latest Isuzu D-MAX, available at any authorized Isuzu dealership nationwide. To locate a dealership, visit www.isuzu.net.my.