In March 2022, the Audi RS Q e-tron won its first desert rally in Abu Dhabi, an important achievement for an electrically-powered vehicle. Audi was the first carmaker that committed to develop a viable alternative drive concept for the gruelling event, making it a pioneer in motorsport.

The original RS Q e-tron development had been rushed as it had to be done during the difficult period of the coronavirus pandemic in 2021 and limited testing opportunities. However, with the experience and learnings from that tough first event, Audi Sport’s engineers have developed a new and significantly improved prototype which will be entered in the 2022 Morocco Rally and the 2023 Dakar Rally.

“We’ve managed a good debut at the Dakar with the Audi RS Q e-tron and even our first stage victories in a motorsport discipline that is new to us,” said Rolf Michl, Managing Director of Audi Sport GmbH and responsible for motorsport at Audi. “The entire team is working excellently together and pulling in the same direction. As is usual at such an early stage, the drivers, co-drivers and technicians quickly agreed on the next development targets. We have summarized the result in a new evolution package – the RS Q e-tron E2.”

Second phase of development program

Reminiscent of the legendary Audi Sport quattro in its final development stage for Group B rallying in the 1980s, the body is completely new and features significantly enhanced aerodynamics. It also has a lower weight and centre of gravity.

“The Audi RS Q e-tron E2 does not adopt a single body part from its predecessor,” said Axel Loffler, Chief Designer of the RS Q e-tron. In order to comply with the prescribed interior dimensions, the cockpit, which was previously narrowly recessed towards the roof, is now significantly wider. The front and rear hoods have also been redesigned.

“We are now doing away with the underflow of the rear hood to the left and right of the B-pillars. In conjunction with modified lay-ups – optimized fabric layers of the composite materials – this solution reduces weight,” said Loffler.

The T1U prototypes will have to weigh 2,100 instead of 2,000 kgs in the future. Given that the first generation of the RS Q e-tron was overweight, it was still necessary to save several dozen kilograms. This is accompanied by the lowering of the vehicle’s centre of gravity.

New aerodynamic concept

The aerodynamic concept in the area of the body below the hoods is completely new. This section is somewhat like the shape of a boat’s hull: its widest point is at the height of the cockpit, while the body tapers significantly towards the front and rear.

The designers dispensed with the part of the fenders that was behind the front wheels and formed the transition to the door. Internally, this structure was called the ‘elephant foot’ and as a result, it saved more weight and optimized the airflow.

“The aerodynamic aspect should not be underestimated in desert rallying either,” said Axel Loffler, Chief Designer of the RS Q e-tron. “Admittedly, the new cockpit dimensions mean that the body has a larger and therefore less favourable cross-section. Nevertheless, it was possible to reduce the overall aerodynamic drag by around 15%. But this does not change the top speed, which remains limited to 170 km/h in the regulations.”

Nevertheless, the improved airflow offers one major advantage. “It further reduces the energy requirements of the electrically powered car,” explained Loffler. “We implemented the aerodynamic calculations entirely using computational fluid dynamics. These computer simulations replace the time-consuming work in the wind tunnel and still deliver highly precise results.”

Simplified operation in the cockpit

The drivers can look forward to their new workplaces. The displays are still in the driver’s field of view and located in the centre console in the usual style, and the central switch panel with its 24 fields has also been retained. However, the engineers have restructured the displays and controls.

They can also work much more easily when there is a puncture, which is not uncommon in off-road events. Simple, flat and easily removable body components replace the previous bulky covers for the spare wheels in the flanks. The new 10-spoke rims are much easier to handle, making the change of wheels safe and quick.

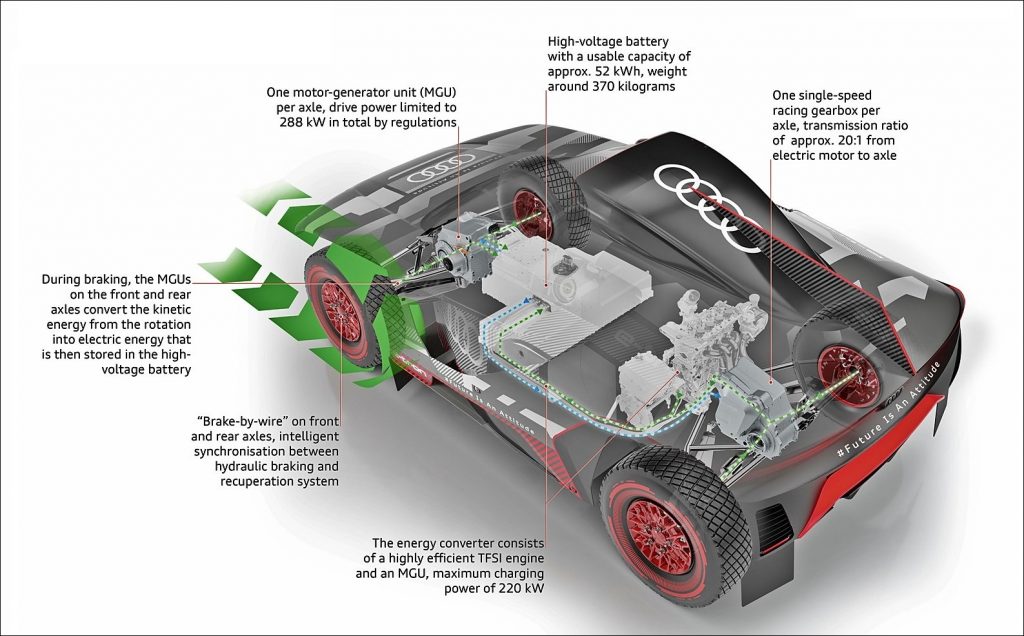

New operating strategies further improve the efficiency of the electric drivetrain. The drivetrain of the RS Q e-tron E2 comprises an energy converter consisting of an internal combustion engine and a generator, as well as a high-voltage battery pack. Two electric motors are used to power the front and rear axles.

Better energy management

Energy management plays a crucial role here. The electronic control system of the complex electric drivetrain proved its worth in the first rally events and issues only occurred in extreme cases. At the Dakar Rally, for example, it was noted that there were short-term surpluses of power in situations where the wheels made less contact with the ground while jumping or on uneven terrain.

The so-called auxiliary consumers also benefit from optimized control. The servo pump, the air-conditioning cooling pump and the fans have a measurable impact on the energy balance. In the course of the debut season this year, the Audi and Q Motorsport rally team gained valuable experience that enables better assessment.

The air-conditioning system, for example, works so aggressively that it could cause the coolant to freeze when constantly running at its maximum output. In the future, the system will run in an intermittent mode. This saves energy, yet the interior temperatures only fluctuate slightly, even over longer periods.

“We have combined all the important lessons in a very short time. The result of our ideas is the E2 evolution,” says Uwe Breuling, Head of Vehicle Operations Audi Sport. “Our development team’s determined and cost-efficient work has prepared us perfectly for our second Dakar Rally.”