It’s difficult to say which was the first hypercar the term itself refers to a car with extremely high performance, beyond the normal performance limits of supercars. It could be based on a minimum power output, say 800 bhp, or it could be dependent on the era as technological levels have constantly advanced.

The Bugatti Veyron launched in 2005 with 987 bhp (1001 ps) could be a candidate for the first hypercar. In any case, there are now a number of models which produce in excess of 1000 ps and therefore qualify as hypercars.

The appearance of hypercars has inevitably led to the creation of a category in motorsport which has seen the first racing cars competing this year. The Hypercar category, a joint project of the FIA and the ACO, envisaged as the new top class of the FIA World Endurance Championship, has attracted a number of carmakers with 13 full-season Hypercar entries from 7 manufacturers.

Shift in regulatory approach

The appeal of this new category has been a shift in the regulatory approach which allows racing to LMH and LMDh technical regulations. It represents a major shift in philosophy compared with the LMP1 class it has replaced. It allows for far greater variety both in terms of technical approaches as well as the aesthetics of the cars, at the same time ensuring sporting equality and preventing cost escalation through the concept of performance windows.

Technical Regulations are focused on controlling performance outcome instead of setting design or geometrical restrictions, allowing manufacturers to choose cost-effective solutions as significant expenditures do not translate to performance gains.

This autonomy allows the automakers to maintain the spirit of the brand and remain relevant to their road car philosophy, but also to express potential in terms of creativity and innovation. Less rigid aerodynamic constraints established for the cars give them the option to incorporate styling elements into the design.

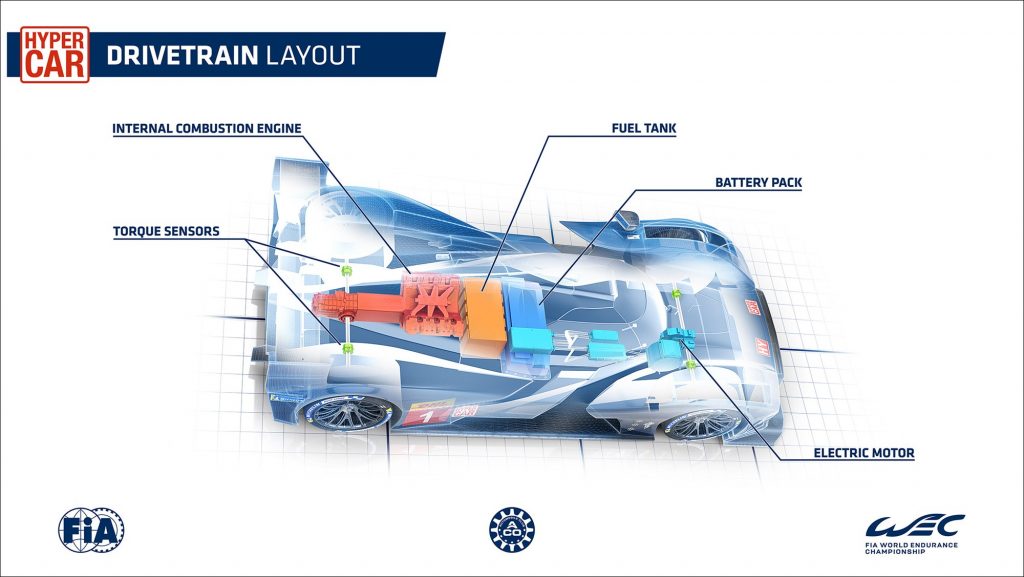

Similarly to the LMP1 class, both hybrid or non-hybrid power units with transmission to either rear or both axles are allowed.

Performance Windows

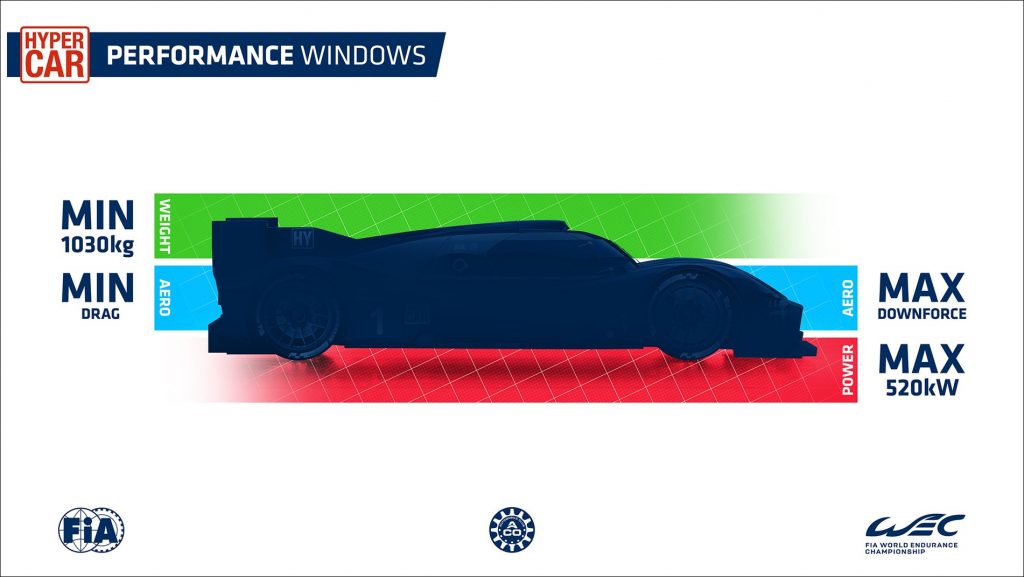

The principle of performance windows is a new regulatory approach to the category. It has been made possible by the application of precise modern methodology for measuring performance parameters, combined with the experience of efficient data acquisition and analysis processes.

Instead of constraining the design process with geometric requirements, the FIA and the ACO are overseeing the outcome. This is possible owing to the concept of performance windows, where minimum and maximum values were set for areas such as weight, power and aerodynamic performance, with each of the cars having to fit into those windows. The maximum power is set at 520 kW, while the minimum weight at 1030 kgs.

During the homologation process, the cars are measured in the wind tunnel, the bodywork is scanned, while the engine performance is measured live on track with the use of torque sensors. This is to ensure that the cars fit into the performance windows. The design of the cars is then ‘frozen’ for their homologation cycle, ensuring they will remain unchanged through their life span.

Balance of Performance

In order to ensure sporting equality, there is the Balance of Performance (BoP). This has been tailored specifically for the needs of the new category, leaning on the knowledge and experience gained over the years. BoP, however, is not new and has been in use since the mid-2000s in a wide range of events from Cross-Country to GT racing.

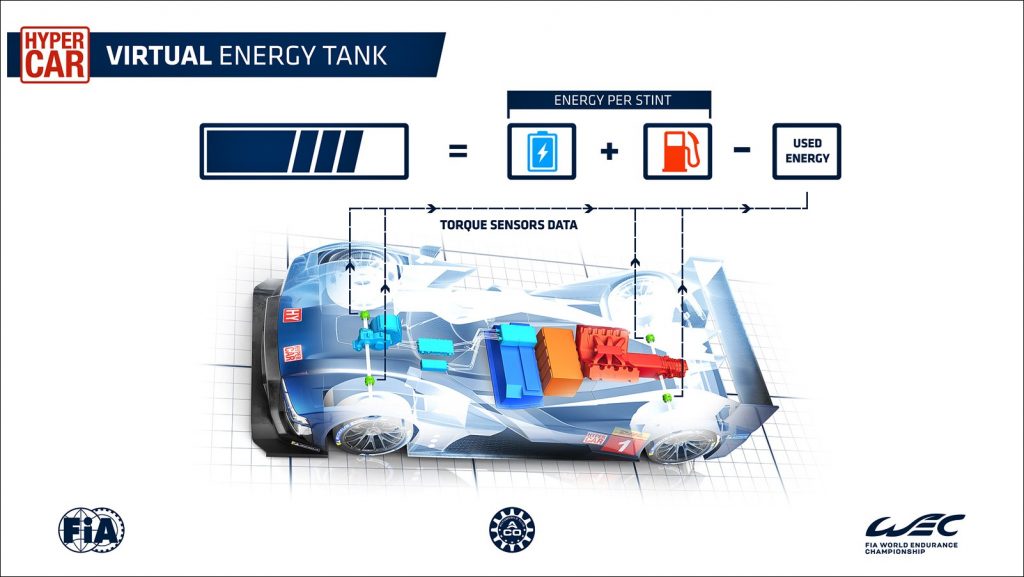

One of the most innovative solutions is the use of torque sensors, allowing for better control of powertrain parameters on track. These sensors, resistant to electromagnetic field and heat, are installed onto the driveshafts of the cars allowing calculation and monitoring of BoP-allocated energy per stint in real-time. This technology is effective in limiting development costs.

For 2023, a new methodology was adopted, with simulations and data from telemetry rather than the lap times playing the biggest role in the process of computing the BoP. This allow the exact same approach to balance every Hypercar against the others by capturing all measurable characteristics.

Cost-saving measures

As avoiding cost escalation is one of the key targets behind the Hypercar concept, several other cost-saving measures were undertaken. To start with, testing is supervised. The use of expensive materials and technology is greatly limited. The minimum weight for the gearbox is set at 75 kgs, with the use of magnesium or aluminium casing and bellhousing mandatory. Furthermore, lower power output results in lower power unit development costs

The suspension is also simplified, with a double-wishbone design compulsory and aids such as active systems and mass dampers forbidden. There is also a single aero kit permitted, without the distinction for Le Mans and the other races. In order to avoid development costs, the tyres are exclusively supplied by Michelin.