After nearly forty years of operations, Proton has officially closed its Shah Alam manufacturing plant, completing the full relocation of its production to Tanjong Malim. The milestone marks the end of a defining chapter in Malaysian automotive history and the beginning of a new era for the national carmaker.

The final unit of the Proton Saga rolled off the Shah Alam assembly line on 30 September 2025, bringing an emotional close to the factory that helped shape Malaysia’s automotive identity since 1985. With that, all production — including the Saga, Persona, S70, and the X-series SUVs — has now transitioned to Proton’s state-of-the-art Tanjong Malim facility, which also houses the brand’s first New Energy Vehicle (NEV) assembly plant under the Automotive High Tech Valley (AHTV) project in Perak.

The Shah Alam plant, built at a cost of RM370 million, was once the heart of Malaysia’s automotive industry. Spanning over 83 hectares, it was home to the country’s first automotive Research and Development Centre and even included a semi high-speed test track — a pioneering setup in its day. Over four decades, the factory produced more than four million vehicles, among them national icons like the Wira, Perdana, and Exora. For many Malaysians, Shah Alam represented more than a factory — it was a symbol of national pride and a cornerstone of local automotive engineering.

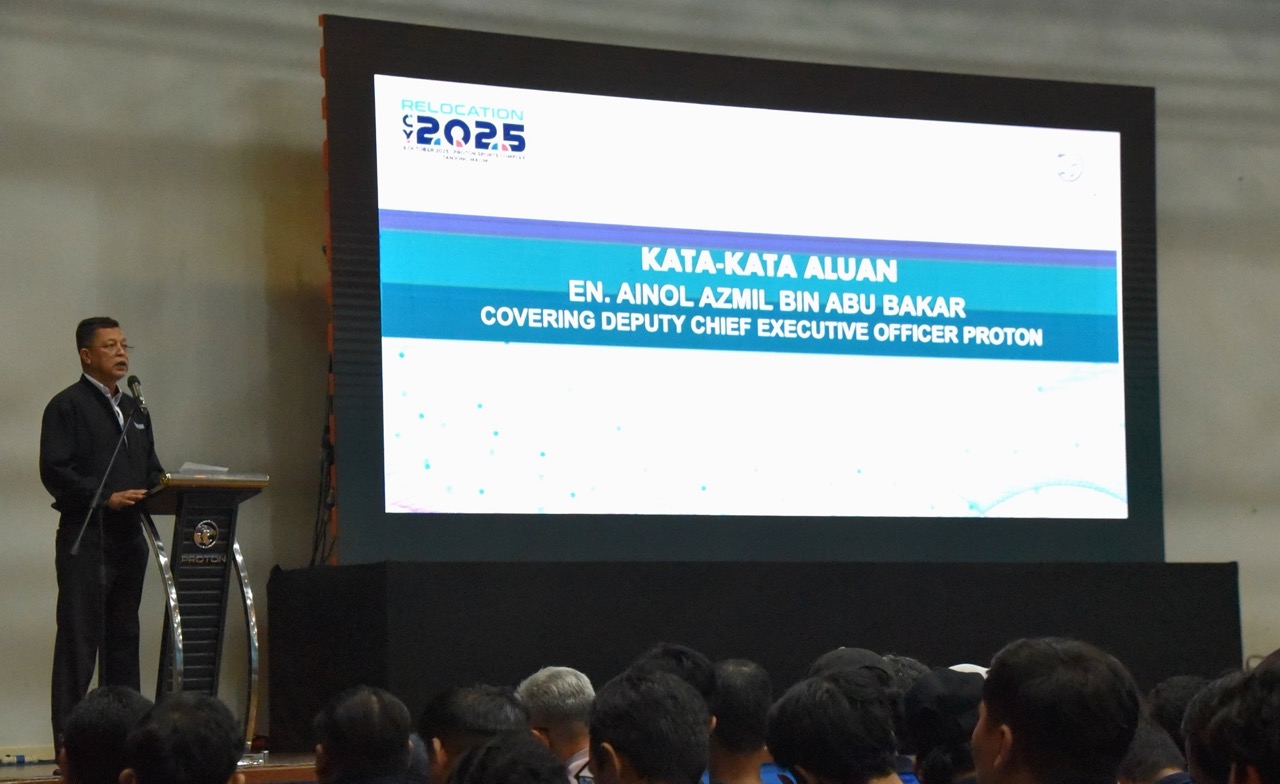

To commemorate the end of one era and the start of another, Proton hosted a welcoming ceremony at its Tanjong Malim plant for the 1,400 employees who were transferred from Shah Alam. The event was officiated by Ainol Azmil, Proton’s Covering Deputy Chief Executive Officer, along with members of the senior management team.

Ainol said the move marked a historic milestone for Proton, as the experience and dedication of the transferred staff would strengthen the company’s future operations. He added that their combined expertise positions Tanjong Malim as the primary hub for the next generation of Proton vehicles.

Now serving as Proton’s main production and development base, the Tanjong Malim plant consolidates assembly, R&D, and component manufacturing into a single advanced facility. It features five major production divisions — Engine and Transmission Machining, Stamping, Body Assembly, Paint, and Trim and Final Assembly — all designed around Industry 4.0 automation and efficiency standards. The facility also houses Malaysia’s largest mechanical press and the first engine assembly line outside of China capable of producing the 1.5 TGDi engine.

With an annual capacity of 250,000 vehicles, the Tanjong Malim complex has become one of the most sophisticated automotive manufacturing sites in the region. It will play a key role in strengthening Proton’s position as both a domestic leader and a regional exporter within the Geely Group’s global network. The site is expected to serve as Geely’s main right-hand-drive production hub in Southeast Asia, contributing significantly to Malaysia’s ambitions in electric vehicle (EV) industrialisation.

Beyond production, the relocation is part of Proton’s broader goal to elevate Malaysia’s automotive ecosystem. The company continues to focus on local sourcing and supplier partnerships while fostering new technical and engineering opportunities tied to EV development.

In many ways, Proton’s move from Shah Alam to Tanjong Malim symbolises the evolution of Malaysia’s national car — from a humble beginning focused on mobility for the people to a modern, high-tech automaker ready for global competitiveness. What once began as a government initiative in the 1980s has now matured into an internationally recognised brand, steering confidently into the next era of innovation and electrification.