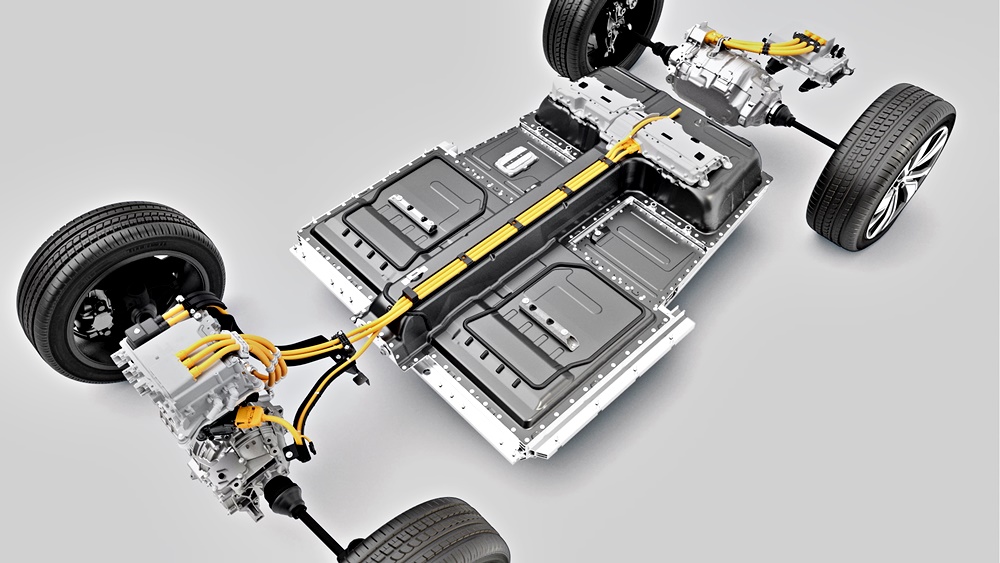

Just as fuel, whether petrol or diesel, is a necessary component for a car with an internal combustion engine to run, electricity is necessary for a full-electric or hybrid electric vehicle to run. Like the liquid fuels which are stored in containers on board the car, electricity is also stored in a battery pack which can be ‘refuelled’ by recharging the pack.

Since demand for batteries will keep growing – even accelerating as electrification progresses – the bigger carmakers that have the financial resources are finding ways to assure supply in future. Some, like BMW, Mercedes-Benz and Hyundai have set up factories around the world while others are establishing joint ventures for such production facilities.

Develop sustainable battery production

The Volvo Car Group has announced plans to establish a joint-venture with Swedish battery company Northvolt to develop and produce more sustainable batteries, tailored to power the next generation of fully electric Volvo and Polestar vehicles.

As a first step for the 50:50 joint-venture, the two companies intend to set up a R&D centre in Sweden that will begin operations in 2022. The centre will draw on the battery expertise within both companies and develop next-generation, state-of-the-art battery cells and vehicle integration technologies, specifically developed for Volvo and Polestar models.

New gigafactory to be built

More significantly, the joint-venture will also establish a new gigafactory in Europe with a potential capacity of up to 50 gigawatt hours (GWh) per year, with production scheduled to start in 2026. As part of the plans, Volvo Car Group also looks to source 15 GWh of battery cells per year from the Northvolt Ett battery plant in Skelleftea, Sweden, starting in 2024.

The new gigafactory, planned to be powered by 100% clean energy, is expected to employ around 3,000 people. The location of the new plant is yet to be decided. The first model to use battery cells developed through the joint-venture will be the electric successor to current XC60 SUV.

This development is a vital one for Volvo Cars’ ambitious electrification plans that will see 50% pure electric vehicles by the middle of this decade and, by 2030, only fully electric cars will be sold. Assured supply is therefore crucial to long-term plans and while planners in some countries imagine that policies affecting the auto industry can be introduced within a short period, the industry requires many years to prepare for changes and execute them.

For Polestar, it gives a further boost to its European growth ambitions and underlines its commitment to the ‘Polestar 0’ project, which aims to create a truly climate-neutral vehicle by 2030.

Reduce environmental footprint

Today, the production of batteries for Volvo Car Group’s fully electric cars represents a large part of the car’s total lifecycle carbon emissions. By working with Northvolt and producing batteries near its manufacturing facilities in Europe, Volvo Car Group can reduce the environmental footprint attributable to battery sourcing and production for its future cars.