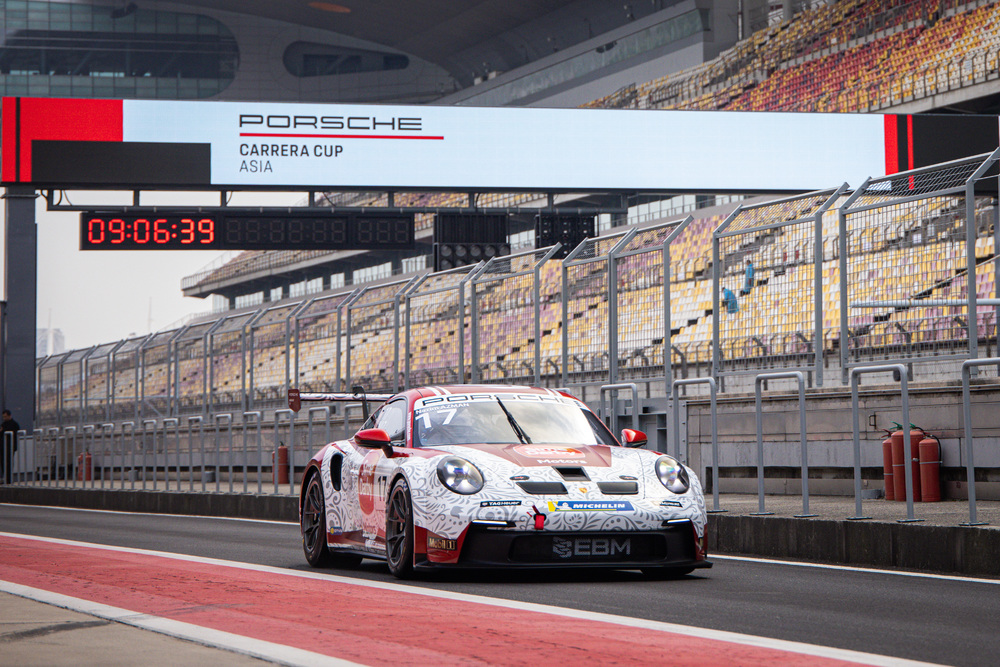

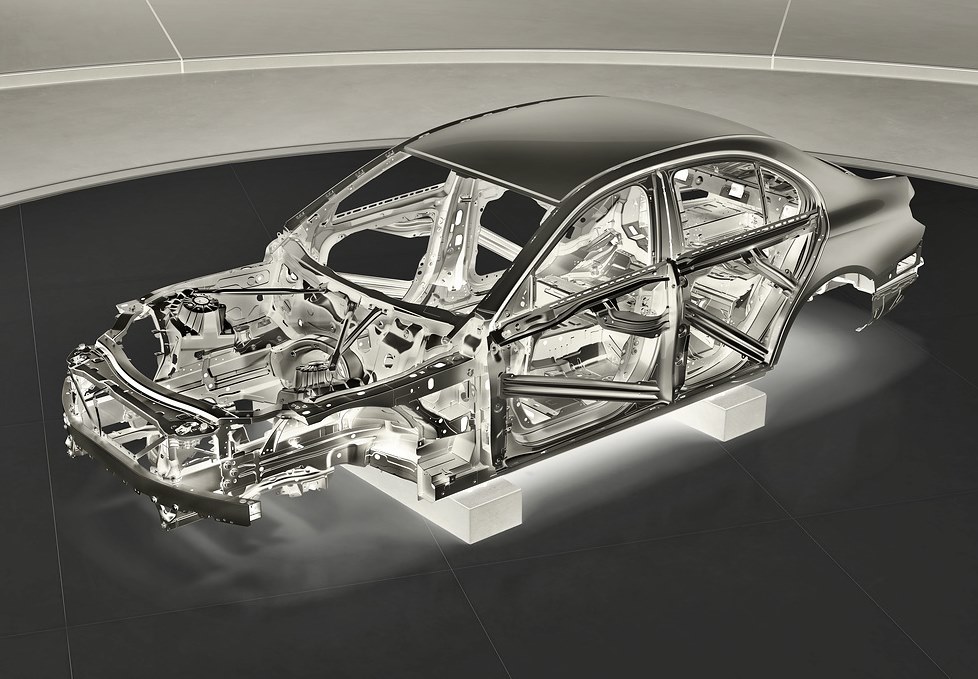

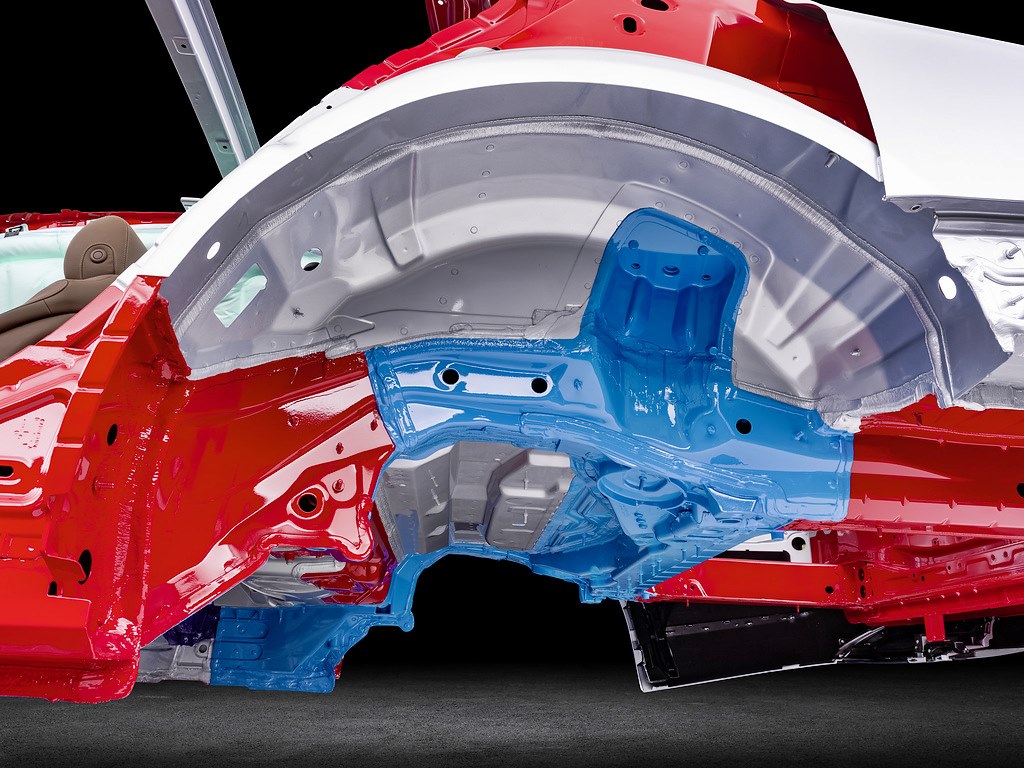

Today’s cars have advanced construction techniques and engineering to not only make them more lasting but also provide better resistance against impact forces during accidents. The materials used are also a mixture of steel, aluminium as well as others like carbonfibre and even titanium. Therefore when it comes to repairs, no longer can the ‘milo tin’ method be used where sheets of scrap steel are just welded onto damaged body.

For this reason, carmakers like Mercedes-Benz have very specific repair techniques using sophisticated equipment to repair damaged vehicles. This ensures that they will be safe to use after repairs and continue to be reliable.

Of course, even the best equipment still requires human operation. Robots could be used but repairing a damaged car also requires human judgement because of the many variables, so fully automated repairs are something in the distant future.

Evaluated by Mercedes-Benz

To ensure that the humans who operate the equipment and carry out the repairs are competent and qualified, Mercedes-Benz trains the personnel and then conducts evaluations regularly. These evaluations are done by a Technical Specialist from Mercedes-Benz Global Service & Parts and the Mercedes-Benz Malaysia Customer Services Team. It includes on-site technical training to ensure its personnel are well trained and meet the Mercedes-Benz standards in restoring a vehicle to its original specifications, from minor dents to severely damaged vehicles.

Thus apart from the investments necessary for a repair facility, a dealership must also ensure that its personnel are well trained and competent. To remain up to date with the latest automotive innovations and technologies, service personnel from authorised dealerships undergo regular up-skilling training at the Mercedes-Benz Malaysia Training Academy. This will become even more important with the new electrified models from the Mercedes-EQ range.

Only two Centres of Competence in Malaysia

In Malaysia, there are only two facilities which have the highest Mercedes-Benz accreditation status – Centre of Competence. The first is the Cycle & Carriage Batu Caves Body & Paint (B&P) Facility in Kuala Lumpur which has twice had a 100% score in the stringent Centre of Competence certification. Now, the Cycle & Carriage Glenmarie Body & Paint Centre at Glenmarie, Selangor, has also received similar accreditation from Mercedes-Benz AG.

The Cycle & Carriage Glenmarie Authorized Service Centre has a total built-up area of 86,600 sq ft containing a workshop, a body & paint centre, a tyre and rim boutique, as well as a vehicle showroom. The workshop is currently equipped to handle 21 vehicles for maintenance and service, and 15 vehicles for body and paint work at any one time.

“With the Centre of Competence accreditation comes equipment and technical know-how to perform complex restoration works including chassis realignment and aluminium structural welding, ensuring original parts are used and work is done by qualified technicians,” said Thomas Tok, CEO of Cycle & Carriage Malaysia, which has been associated with the German brand since 1951.

“At Cycle & Carriage, we put our customer’s safety at the heart of everything we do, including repair and services, and we are proud to say that Cycle & Carriage Glenmarie has achieved the highest Mercedes-Benz accredited status to be able to provide the care and service customers expect from a premium luxury brand,” he said.