Throughout its history of over 100 years, the Morgan Motor Company has produced cars with unique classic designs, with the 3-wheeler model being perhaps the only unusual one. All the cars have been designed for road use although Morgan has a well documented history of competing in all-terrain endurance trials as far back as 1911.

Joint project with Rally Raid UK

Now the company has unveiled the Plus Four CX-T, which is capability never before associated with the brand. It will enable owners to travel on routes normally inaccessible by Morgan cars. It is the second of two special projects by Morgan in 2021, with the first being the Plus 8 GTR. For this project, Morgan partnered with Rally Raid UK, well known for building vehicles for the Dakar Rally.

Demonstrating new CX-Generation platform

One of the aims of the joint project is to demonstrate the capability and durability of Morgan’s new CX-Generation platform, along with the Plus Four upon which the CX-T is based. Just 8 vehicles will be built, each priced at £170,000 (almost 1 million ringgit) at Morgan’s factory with final preparation and set-up at Rally Raid own workshop facilities, both in the UK. Each customer will have the opportunity to work alongside Morgan’s design team to personalise their own CX-T, which will be delivered by the end of this year.

The exterior of the Plus Four CX-T is designed to maximise luggage and equipment carrying capacity, as well as provide the occupants protection necessary for extreme environments. Most prominently, the rear panel of the vehicle has been replaced with an equipment rack, with unique side body panels designed to be reminiscent of the classic 4-seater Morgan.

Features for off-road adventuures

The rack houses two ruggedised and waterproof Pelican luggage cases, a Zarges aluminium tool/storage box, two Rotopax 11-litre containers and two spare wheel/tyre assemblies. Additionally, for those who venture further off the beaten track, recovery equipment is mounted on the bodywork. All exterior mounting systems for storage and equipment have been engineered to be tough and easy to access when needed.

The external protective exoskeleton can also be adapted to carry leisure equipment such as bikes and surf boards, to complement the lifestyle activities of the owner. Removable side screens can be mounted onto the roof, allowing them to be carried unobtrusively in case of a change in weather conditions.

Conversion from Plus Four

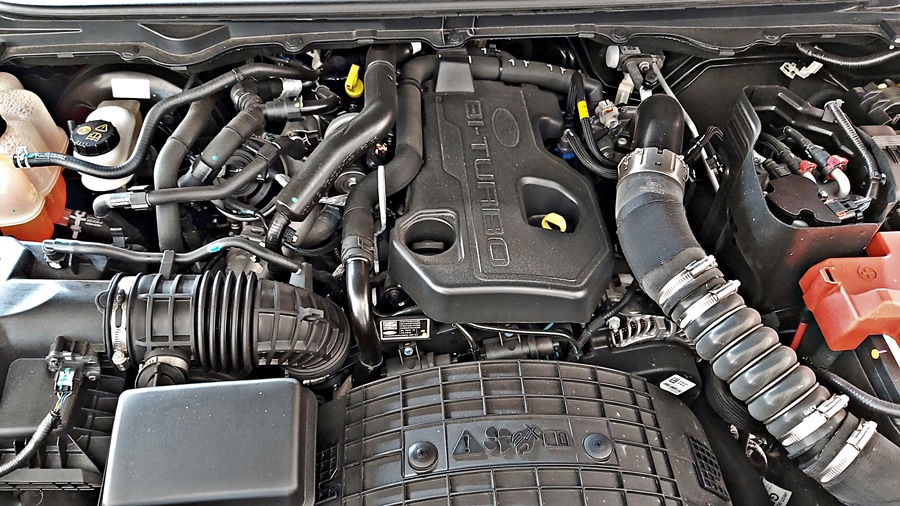

In the initial stage of the project, Rally Raid UK undertook a complete study of the standard Plus Four vehicle with durability assessments of the platform, drivetrain, and suspension systems. The suspension has been designed to be expedition ready, tough and fit for purpose. Durability, and a drive-over obstacle clearance of 230 mm, has been achieved using modified Plus Six wishbones. These widen the track and allow for the extra arc of movement required to achieve the desired suspension performance. The wheel arch apertures have also been modified, allowing the suspension to compress deep into the wheel well, providing maximum traction and stability.

In addition to the main suspension hardware, the lower suspension arms contain bespoke bushes which further increase durability. The combined suspension package is optimised to undertake journeys never before attempted in a Morgan sportscar, while ensuring composure and comfort during any excursion into remote areas.

BMW xDrive differential

A 5-piece underbody protection system helps to protect the chassis and important components from damage when driving in extreme conditions. The car is also fitted with a full bespoke exhaust system with rear side-exit that improves the departure angle and contributes to the higher ground clearance. The Plus Four CX-T is fitted with a BMW xDrive electronic differential with 3 modes to vary the degree of differential lock depending on conditions.

In the cabin, features have been added for occupant comfort and usability in remote environments. The cabin is enclosed within a composite hardtop which is unique to the Plus Four CX-T and has been intricately engineered to fit between the internal and external roll cages.

A RAM mount track is built into to the dashboard to allow the secure fixing of a variety of devices such as smartphones or cameras. A flexible map light, pencil and notebook holder have also been integrated, all designed to withstand operation in harsh driving environments.

Cabin stowage has also been optimised with the addition of a removable map/document holder and insulated cool bag, both located in the passenger footwell. A custom-made first aid kit is mounted to the internal roll cage behind the seats.