Nissan will be stepping up its electrification strategy as it aims to be carbon-neutral across the lifecycle of its products by its fiscal year 2050. With its new long-term vision – Nissan Ambition 2030 – announced today, the carmaker will advance technologies to reduce its carbon footprint and pursue new business opportunities and become a sustainable company.

Having been a strong promoter of electric vehicles (EVs), starting with the LEAF, Nissan will continue to place electrification at the core of the company’s long-term strategy. In this respect, it aims to accelerate the electrification of its vehicle line-up and rate of technology innovation with investments of 2 trillion yen (about RM76.2 billion) over the next 5 years.

23 new electrified models to come

By fiscal 2030, the Nissan range will see 23 new electrified models, including 15 new EVs, to achieve an electrification mix of more than 50% globally across the Nissan and Infiniti brands. Within the next 5 years, 20 new EV and e-POWER equipped models will be launched and with these new models, more than 75% of sales in Europe will be electrified models by 2026. In Japan, the mix is expected to be more than 55% of sales, while in China, it will be more than 40% of sales.

“We are proud of our long track record of innovation, and of our role in delivering the EV revolution. With our new ambition, we continue to take the lead in accelerating the natural shift to EVs by creating customer pull through an attractive proposition by driving excitement, enabling adoption and creating a cleaner world,” said Nissan COO Ashwani Gupta.

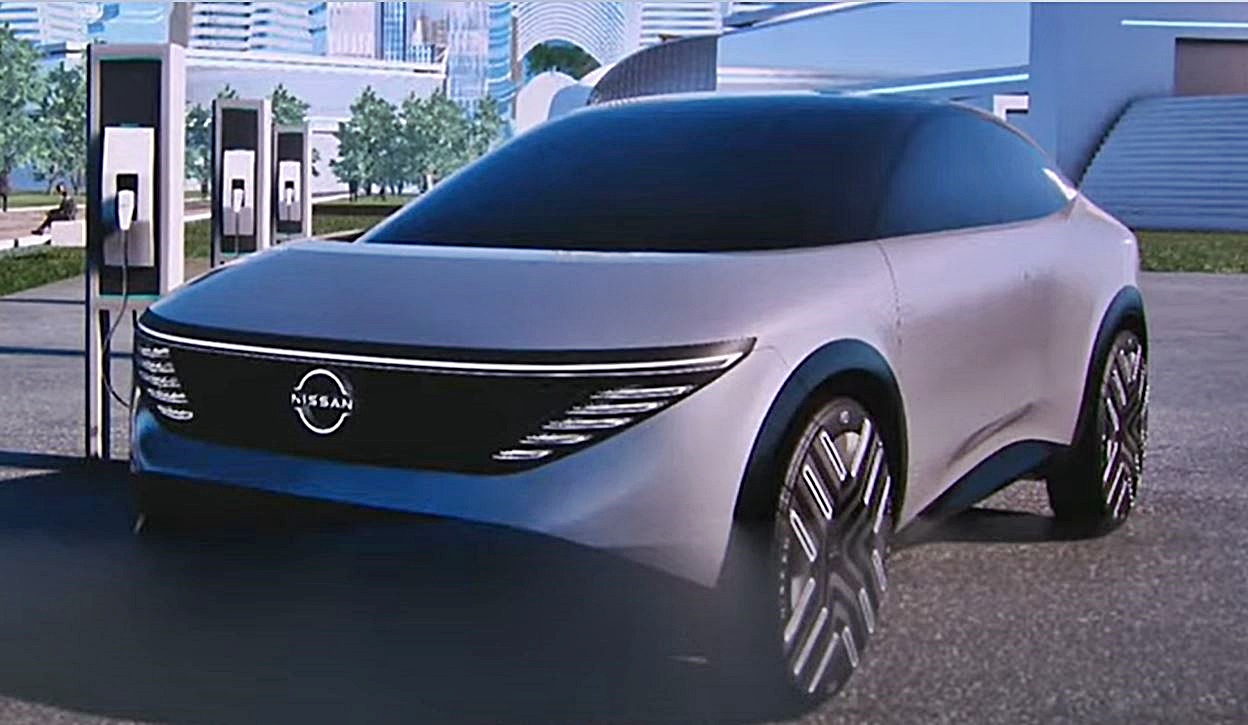

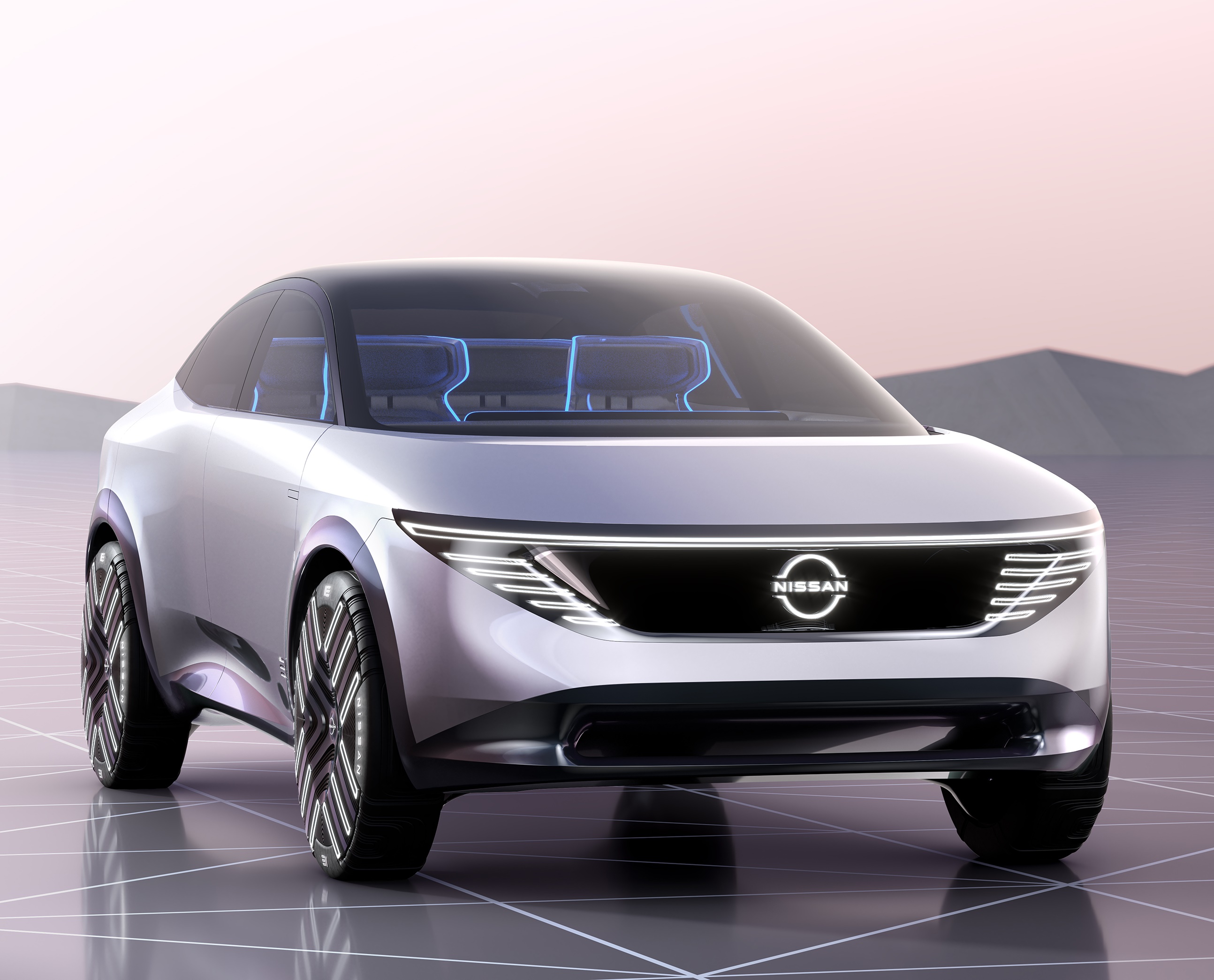

Representing the next stage of Nissan’s electrified future, the company today also unveiled three new concept cars that offer enhanced experiences through sophisticated technology packaging. These concept cars are being developed under Nissan EV Technology Vision, a technology study that looks beyond the Ariya and next-generation crossover EV. The technology considers the direction of future EVs, and how advancements in battery technology, hardware and packaging can offer customers a wide variety of mobility solutions to match their needs and lifestyles.

All solid-state battery (ASSB) technology

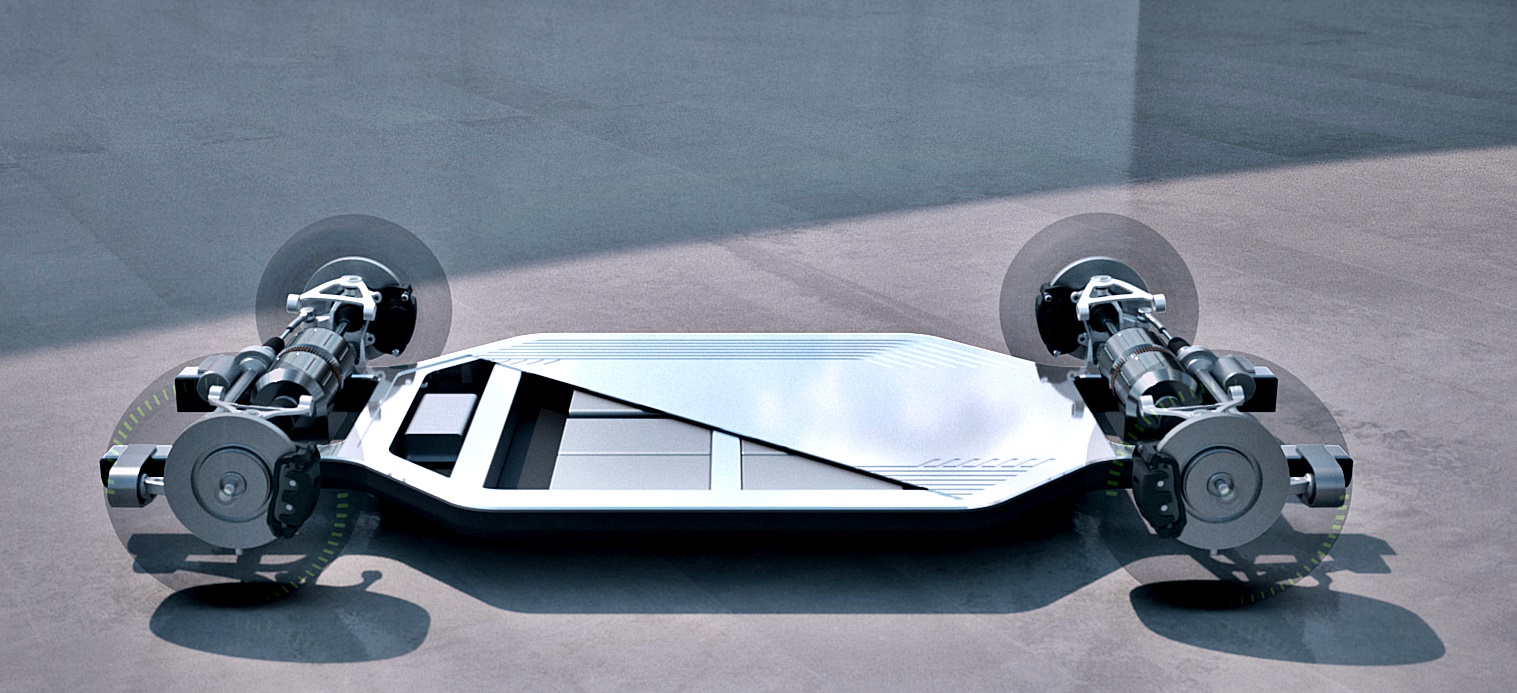

At the core of Nissan EV Technology Vision is the integration of all solid-state battery (ASSB) technology that integrates with optimized components into a skateboard-like structure that allows for a variety of vehicle types. The optimum hardware structure will bring out the full potential of future complex software configurations and further realize the precision, performance, efficiency and versatility of EV offerings. Recharging time will be reduced to one-third, it is claimed.

ASSB, which offers innovative integration of the body, chassis and battery pack, has ideal geometry with electric drive. Motors are located at the front and rear and together with a very low centre of gravity and ultra light weight, optimal mass distribution can be achieved. To efficiently manage and operate the vehicle precisely, AI (artificial intelligence) will also be integrated and this includes technologies such as Advanced e-4ORCE and Advanced ProPILOT.

Nissan will also continue to advance its lithium-ion battery technologies and introduce cobalt-free technology to bring down the cost by 65% by fiscal year 2028. The proprietary ASSB will be installed in EV models by fiscal year 2028.

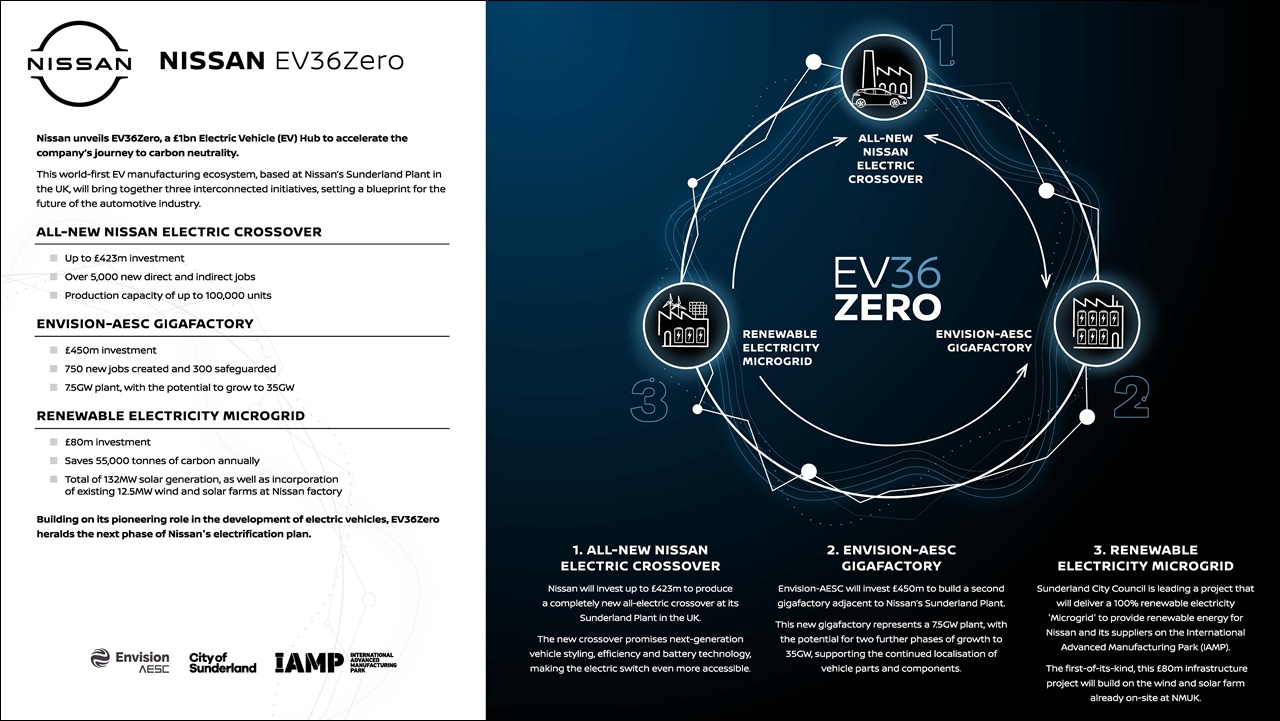

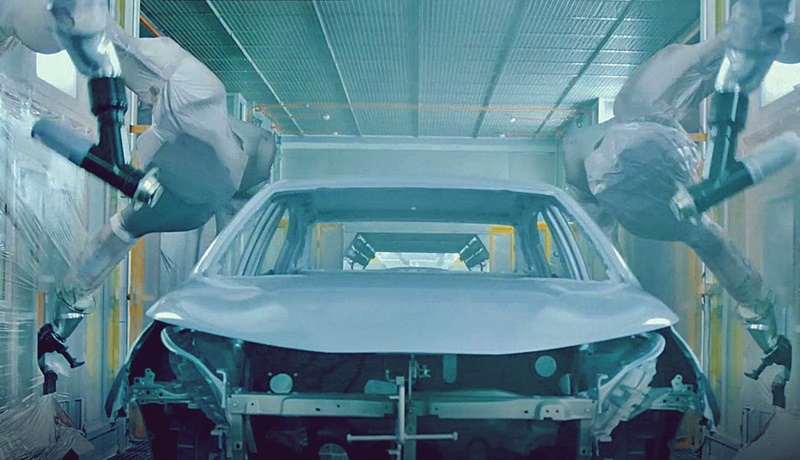

In addition to technology upgrades, Nissan will localize manufacturing and sourcing to make EVs more competitive. The carmaker will expand its unique EV Hub concept, EV36Zero, which was launched in the UK, to core markets including Japan, China and the USA. EV36Zero is a fully integrated manufacturing and service ecosystem connecting mobility and energy management with the aim of realizing carbon neutrality.

Preview of future models

For those who worry that electrification will mean the end of sportscars from Nissan, this seems unlikely to happen. Even in the EV age, there will be sportscars although they may have a different sort of feel from today’s musclecars with combustion engines. They will still offer impressive performance, thanks to the high torque characteristics of electric motors.

The Max-Out concept (above) is one idea which Nissan designers are looking at and it is a convertible. Technical details are not available at this time but there is the promise of ‘a new driving experience with superlative stability and comfort’. The low centre of gravity will provide dynamic cornering and steering response with limited body roll and the occupants will feel united with the car. The 2-seater has a unique ability to morph the seating, flattening into the floor for more interior space when needed. This would be ideal when the driver is out on the road alone.

The Max-Out will have Advanced e-4ORCE which offers powerful, smooth and high output, ride comfort, and independent brake control. This electric-drive 4-wheel-control technology integrates Nissan’s electric propulsion and 4WD control technologies with chassis control technology to achieve a huge leap in acceleration, cornering and braking performance on par with the latest sportscars.

The Surf-Out concept (above), as the name suggests, is more of an adventure concept with the bodystyle being that of a compact pick-up. It is all-terrain capable and could have a variety of power outputs to suit different conditions. The low and flat cargo space will make stowing gear convenient, while the vehicle can also supply electric power for other devices or equipment. Like the Max-Out, this concept vehicle is also engineered with Advanced e-4ORCE.

With the Hang-Out concept (above), the designers are exploring new ideas for interior layouts. This is possible as the floor is completely flat from front to rear. Thus, the cabin can be a mobile living room which travels off the highway. Theatre-style seating will make viewing movies on the built-in display enjoyable for everyone. Special effort is made to suppress vibrations and jolts so that the occupants are less likely to experience motion sickness.

The driver will have the support of Advanced e-4ORCE and Advanced ProPILOT to make journeys safer and more comfortable. ProPILOT technology is already available in some Nissan models as the carmaker was the first to introduce a combination of steering, accelerator and braking that can be operated in full automatic mode. This technology enables autonomous operation during highway driving in single-lane traffic.

Nissan aims to expand ProPILOT technology to over 2.5 million Nissan and Infiniti vehicles by fiscal year 2026. The company will also further develop its autonomous vehicle technologies, aiming to incorporate next generation LIDAR systems on virtually every new model by fiscal year 2030.

Besides the three models, a more advanced concept model is the Chill-Out (above), which shows some of the design language that we might see in future Nissan vehicles. It sits on the modular CMF-EV platform of the Renault-Nissan-Mitsubishi Alliance.

Designed specifically for electric vehicles, the CMF-EV platform is exceptional in its modularity. For example, it allows for the installation of batteries of different heights which means it can be used for low sedans as well as SUVs which have more ground clearance. The platform is variable in its length, making it applicable for more different types of vehicles.