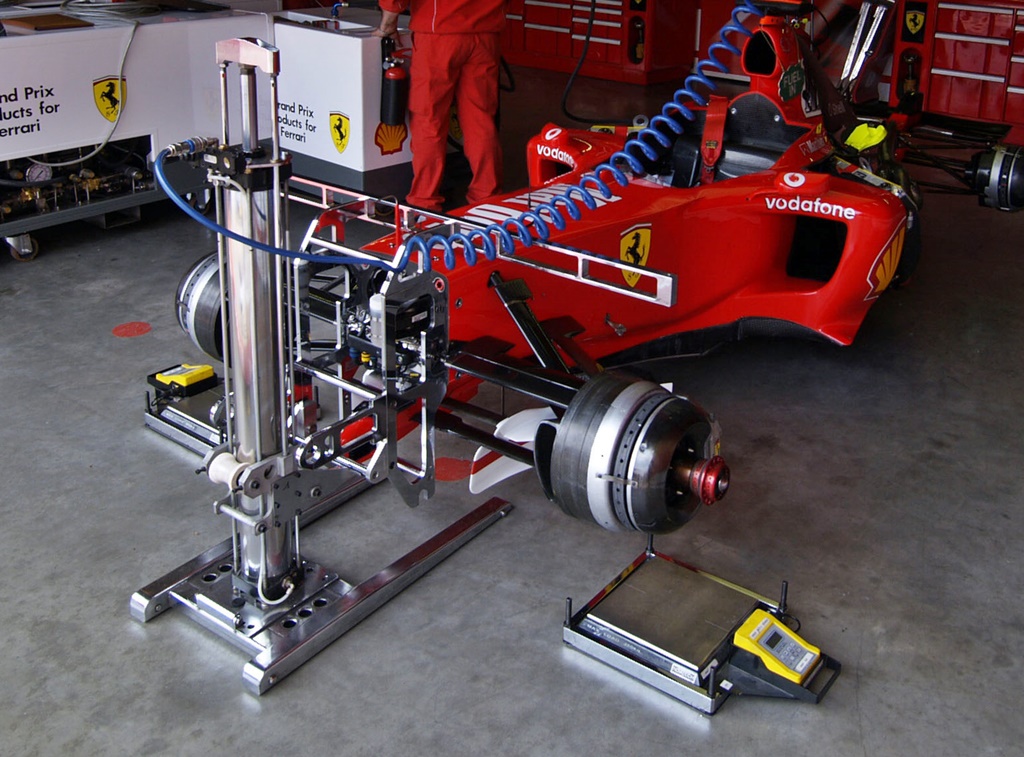

This weekend sees the start of the 2022 Formula 1 World Championship in Bahrain, and it will be a bit different from previous seasons. The cars will be new, not just upgraded from the previous year, to meet the biggest technical changes in F1 regulations in some four decades. The changes made include a switch from 13-inch wheels to 18-inch wheels, which has also meant new custom brake systems.

As before, Brembo is the main supplier of the brake systems, and the engineers are starting off the season on a circuit known to be one of the most demanding for brakes. On a difficulty index scale of 1 to 5, it is a 4 – exactly the same as legendary tracks like Monza and Spa-Francorchamps, albeit with very different characteristics than these.

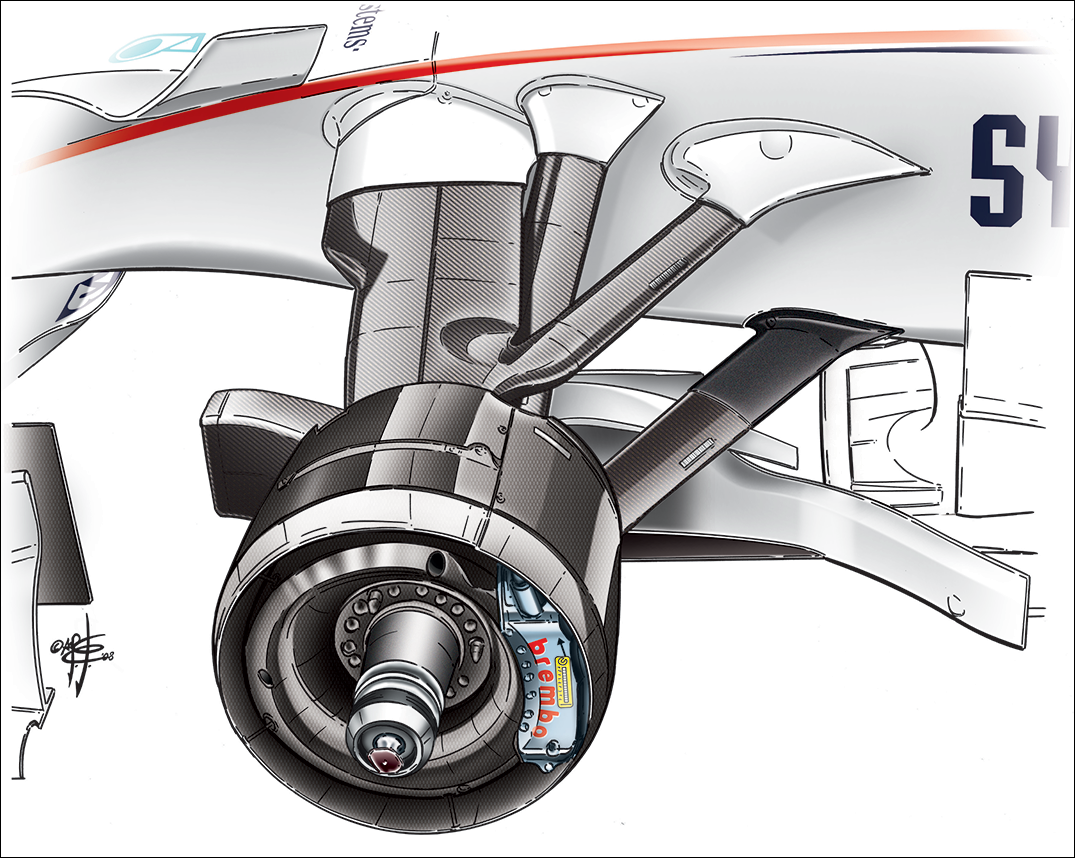

The Bahrain GP will be a test bench for the new systems, partly because of an asphalt that is usually extremely abrasive, with the sand clearing off lap after lap and where the wind often plays a determining role. Furthermore, the race will start after sunset, so temperatures will change as well However, this year the presence of lenticular wheel covers, also brand new, will keep spectators from enjoying the view of the incandescent carbonfibre discs during braking at the end of the straights.

Disc size and hole size change

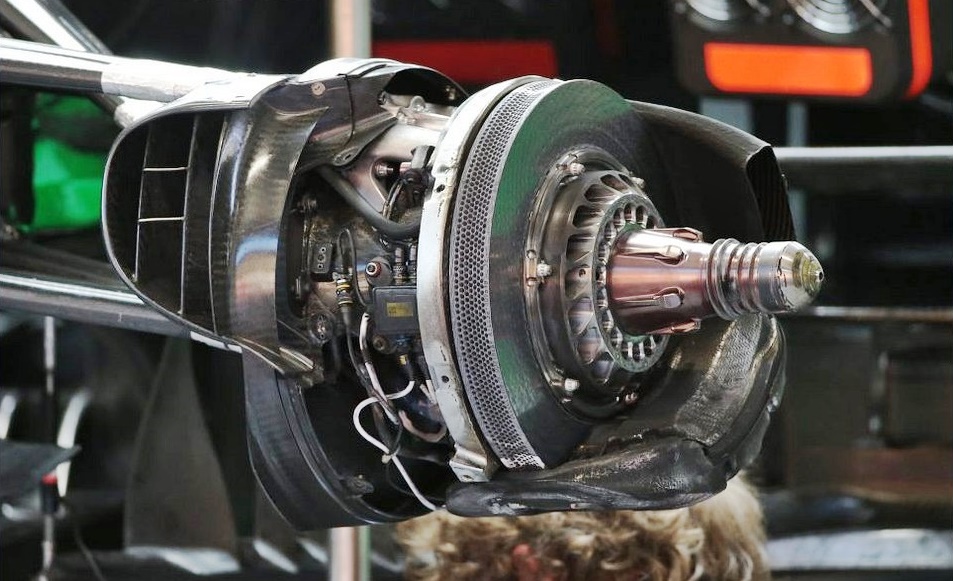

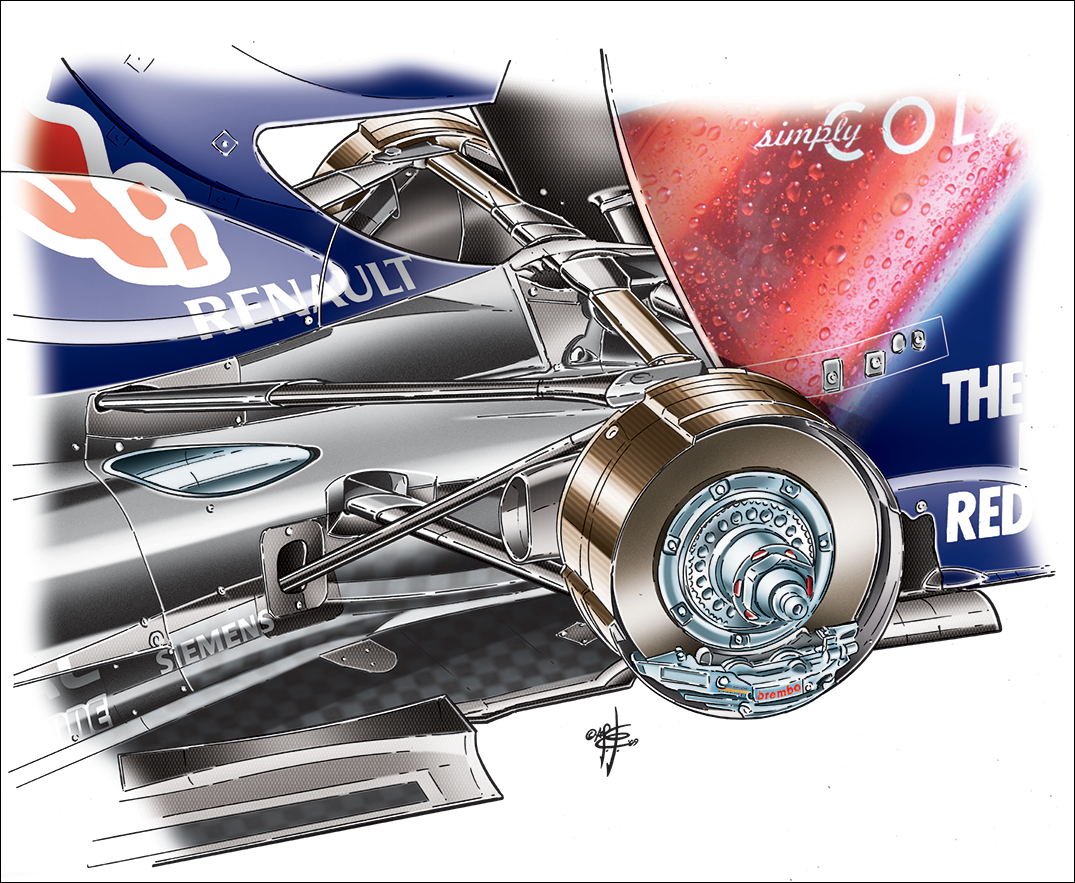

The increase in wheel diameter from 13 inches to 18 inches provides more space in the wheel corner for the carbonfibre disc. This has allowed their diameter to increase from 278 mm to 328 mm for the front and from 266 mm to 280 mm for the rear.

The thickness of the discs is now identical for both axles, 32 mm, compared to last year when the rear discs did not exceed 28 mm. However, the architecture of the discs has also changed because the new technical regulations impose a minimum diameter of 3 mm (0.12 in.) for the ventilation holes whereas, in the past, Brembo pushed the envelope as far as 2.5 mm.

Brembo has researched the shape of the ventilation chamber in brakes for over a quarter of a century. The use of thermo fluid dynamic calculations allowed the best choice between traditional fins and pillar ventilation for each disc type. The latter, ideal when there is not a constant airflow within the disc, are arranged on three circumferences along the braking band with geometry designed to ensure the best performance for fluid dynamics. In these conditions, the pillars increase resistance to thermal cracking by up to 30%, ensuring longer life for the discs which can reach 1,200°C in the racing cars.

4 hard braking sections

On each lap of the Bahrain track, the drivers use the brakes 8 times for a total of 16.5 seconds, although a large part of this time is spent on the 4 hardest braking sections which require the braking system to work for just under 2.9 seconds on average. On the other hand, on 3 turns, the braking time is less than 1.5 seconds and the braking distance is 90 metres.

The twisty nature of the circuit is best represented by the fact that there is only one point where speeds reach well above 300 km/h. Nevertheless, there are 6 braking sections with maximum deceleration of almost 4g, with a peak of 4.6g on the first turn.

131 metres to decelerate 248 km/h

Of the 8 braking sections at the Bahrain GP, 3 are classified as very demanding on the brakes, 4 are of medium difficulty, and the remaining one is light. The most difficult time for the brake system is at the first turn because the cars are coming off a 1.1 km straight. The drivers will hit the brakes at 328 km/h and the speed must drop to 80 km/h in just 131 metre (429.8 feet). To achieve this, the drivers brake for 2.95 seconds and experience a 4.6g deceleration.

A tip for videogames

Tackling Turn 1 on the Bahrain International Circuit in the Formula 1 videogame only takes a few things: you have to start braking with the wheels straight at the end of the section where you can use the DRS, using the 100-metre sign as your point of reference. You should reduce the pressure on the pedal progressively and then move to the right, but without touching the curb in order to avoid being unbalanced, which would make you lose power.