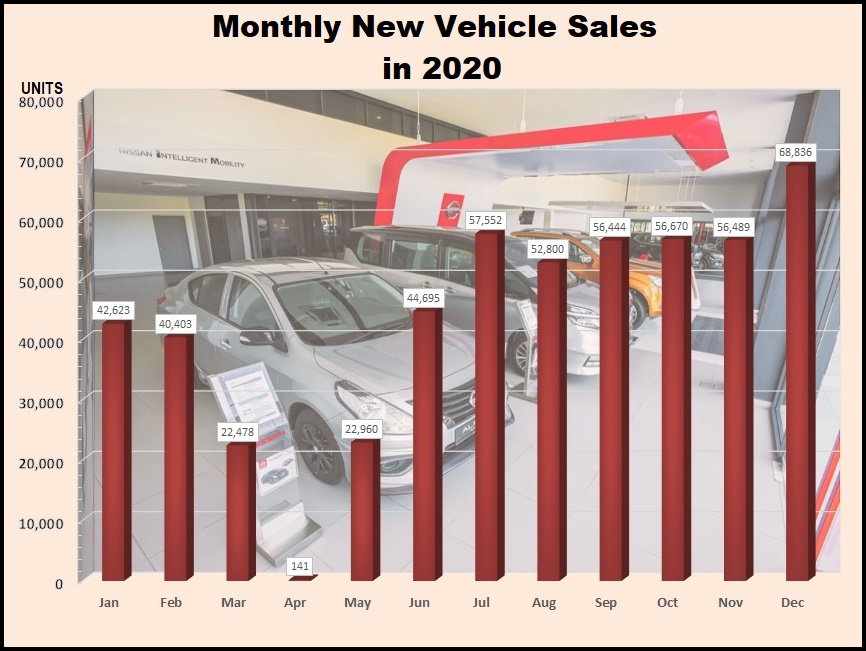

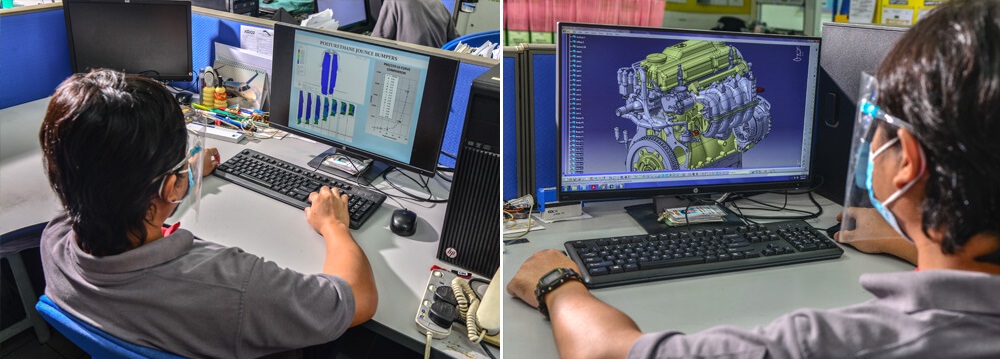

With the accelerated pace of development in industries, a revolution is taking place and where the automotive industry is concerned, this revolution will take companies to the next level with cutting-edge technologies, processes and machinery. This transformation of the automotive industry is referred to as Industry 4.0., a term inspired by Germany’s ‘Industrie 4.0’, a government initiative to promote connected manufacturing and a digital convergence between industry, businesses and other processes.

To promote the adoption of Industry 4.0, the Malaysian Investment Development Authority (MIDA) and Perodua are gearing up through a strategic partnership to introduce the MIDA-Perodua Digital Transformation Ecosystem Programme. The programme aims to upgrade local automotive suppliers and to digitalise their manufacturing processes through adoption of Industry 4.0.

Developing local players’ capabilities

“Local companies play a major role in building the nation’s industry ecosystem–geared to support large companies and MNCs. The initiation of the MIDA-Perodua collaboration in 2020 was crucial to ensure a steady development of our local player’s capabilities in the automotive industry,” said Datuk Arham Abdul Rahman, Chief Executive Officer of MIDA.

“Under MIDA’s initiative to facilitate these companies to adopt digitalisation and Industry 4.0, we have been successful to contributing immense growth in Perodua’s manufacturing volume, through the empowerment of its industry partners and service providers.” he said.

Local technology ecosystem development

According to Dato’ Sri Zainal Abidin Ahmad, Perodua’s President & CEO, the MIDA-Perodua Digital Transformation Ecosystem Programme is aligned with the government’s efforts to enhance local technology ecosystem development activities in terms of supply and value chains, research and development activities, and innovation and commercialisation. The programme has shown a promising sign as the first group of participants had implemented their proposed projects.

“The implementation of Industry 4.0 is not only for the automotive supplier’s benefit, but the impact of this programme will contribute greatly to the national’s digital transformation agenda. The programme also can fast-track Malaysia’s industries, from small to large, as it provides both funds and guidance,” Dato’ Sri Zainal Abidin said.

“Perodua’s role has always been to develop the automotive ecosystem and this programme is another example of our commitment towards this objective,” he added.

Eight participants in programme

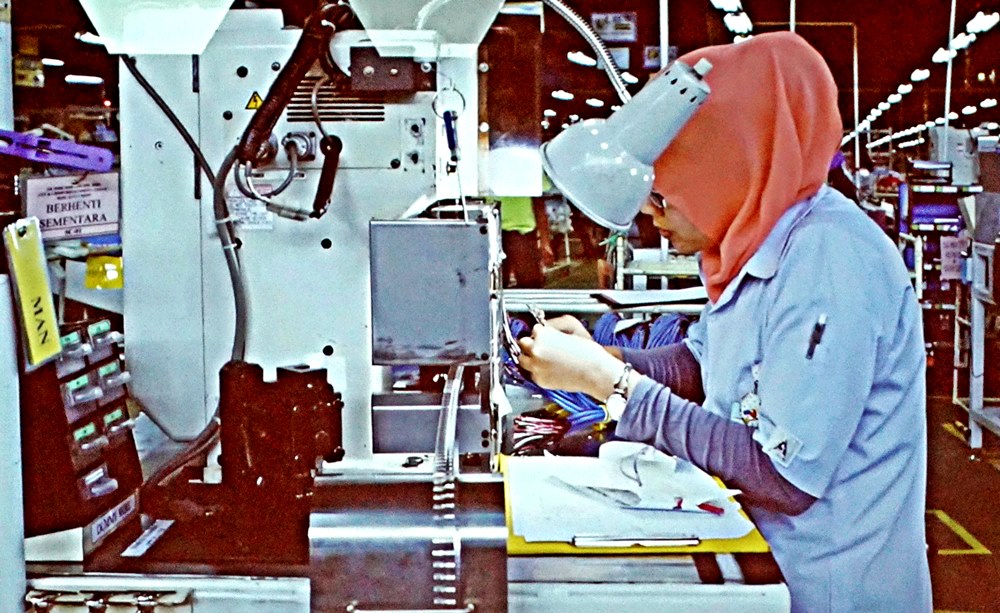

The first phase of MIDA-Perodua strategic partnership has brought forth three potential Perodua-friendly partner – LSF Technology Sdn.Bhd., J.K. Wire Harness Sdn. Bhd. and Autoliv Hirotako Safety Sdn. Bhd. These companies have also been granted Domestic Investment Strategic Fund as part of the government’s initiative to assist the local companies to embark into the global supply chain.

Moving forward to Industry 4.0, MIDA and Perodua have identified five more vendors with much potential and growth opportunities. These are Armstrong Auto Parts Sdn. Bhd., Ingress Aoi Technologies Sdn. Bhd., Namicoh Suria Sdn. Bhd., P.D. Kawamura Kako Manufacturing Sdn. Bhd. and Kumpulan Jebco (M) Sdn. Bhd.

MIDA, being the pivotal principal promotional agency of Malaysia, will be extending their support services to help more companies obtain growth in terms of productivity, talent and bridging financial and technology gaps.

The agency is confident that through such facilities and empowerment measures, these automotive players will be able to increase their business offerings and expertise to innovate its products and services and climb the supply chain ecosystems.