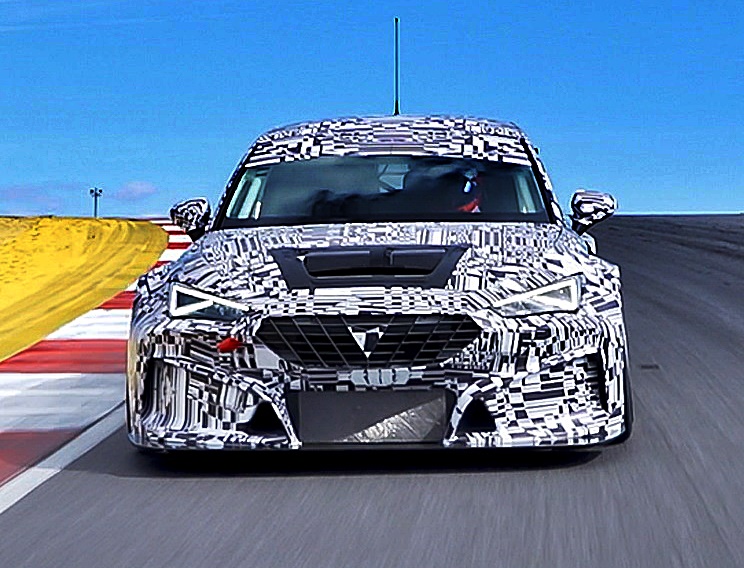

An all-new Audi A3 will make its world debut at next month’s Geneva Motor Show and to give selected media a preview of its dynamic capabilities, the carmaker held a test-drive in the Azores islands in the Atlantic Ocean. It’s a place where volcanoes once created a whole chain of islands and where there is a high level of volcanic activity,

Although the island location presents less of a challenge to keeping the new model out of general public view before the unveiling, Audi nevertheless had it camouflaged. The tight winding roads and varied mountain and valley stretches around the island were perfect for showing off the highlight of the new A3 and core of Audi’s DNA: quattro drive.

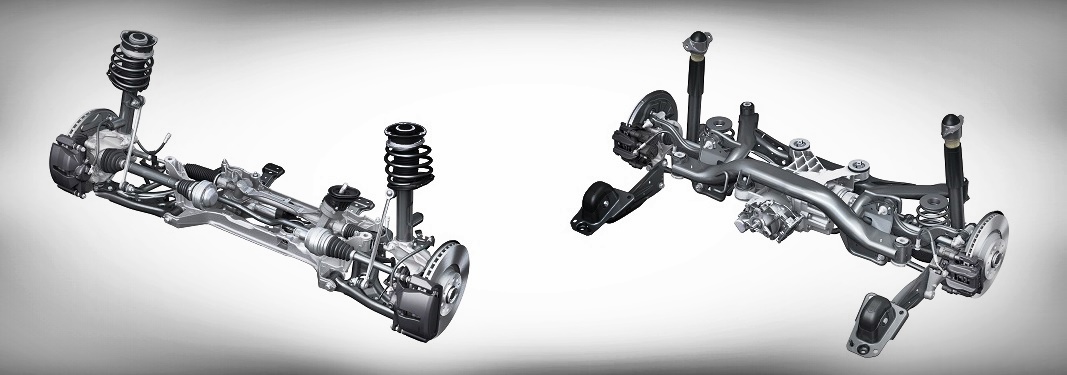

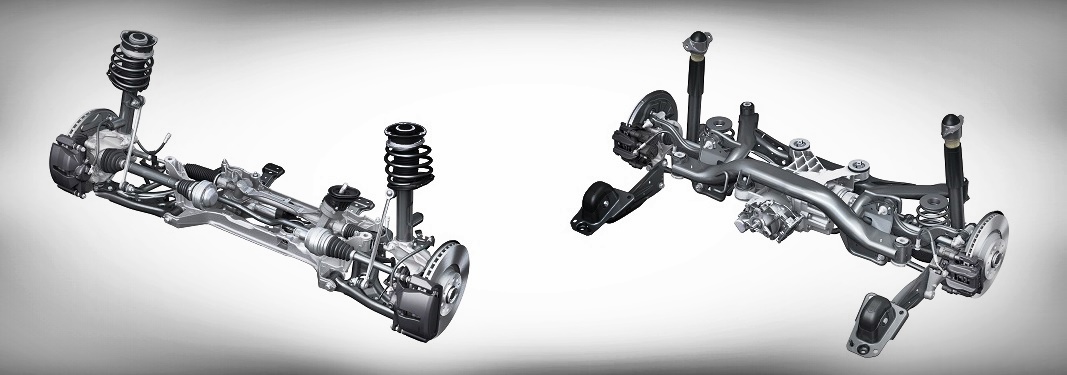

The all-wheel drive system fittingly makes its first appearance in one of the most emotive versions of the fourth generation A3, and represents the latest stage in the evolution of this successful technology, which in Audi models with transverse engine installations is based around an electro-hydraulic multi‑plate clutch.

Intelligent regulation

Managed by precisely tuned software and supported by the adaptive suspension and the progressive steering, the system not only maximises stability, grip, and driving pleasure, but is also extremely efficient. The clutch is located at the end of the propshaft, in front of the rear axle differential – a position that benefits the axle load distribution in particular. Inside is a package of plates that operate in an oil bath. Its metal friction rings are arranged behind one another in pairs – one ring of each pair is rigidly meshed with the clutch housing, which rotates with the prop shaft; the other ring is meshed with the short output shaft to the rear axle differential.

Tailored electronic torque distribution

Audi tailored the electronic torque distribution control specifically to suit the new A3 and integrated it in the Audi drive select dynamic handling system. It takes the data of the suspension sensors into account and detects not only the driving conditions and road properties but also the driving style. The control unit uses this data as a basis to calculate a torque distribution that provides optimum efficiency and passes the value on to the clutch.

The all-wheel drive distributes the torque with full variability between the front and rear axles. During normal driving operation, most of the engine’s power is transmitted to the front wheels. When driving off or when the front axle has little traction, the clutch diverts the torque at lightning speed. In this case, an electric axial-piston pump is activated, which applies up to 44 bar of hydraulic pressure to the clutch plates. The more the clutch plates are pressed together by this pump, the more drive torque is transmitted to the rear axle – the maximum is 100%.

The clutch can already transmit part of the torque to the rear axle when the driver begins to make quicker turns of the steering wheel during more challenging driving. As soon as the driver accelerates, the torque presses the A3 into the corner. During load changes, the distribution of torque allows precise turning into the bend, which further increases driving dynamics.

Full control ESC

The wheel-selective torque control, a software function of the Electronic Stabilization Control (ESC), perfectly complements the latest quattro system. When the new A3 negotiates a corner at high speed, the program applies the brakes slightly to the two wheels on the inside of the bend. The difference in drive forces on both axles turns the car into the bend, allowing it to follow the steering angle precisely. This makes the handling even more agile, fluid, and safe.

New damper technology

Comfortably soft or sporty and taut? Both are possible with the suspension with adaptive damper control which will be available for selected models in the new A3. Three damper settings ensure that the driver can experience the spread of the driving characteristics and enjoy particularly agile handling. Sensors measure the vertical acceleration of the body structure and the relative movement of the individual wheels in relation to it.

The dampers include electromagnetically actuated valves that can be regulated extremely quickly and in a highly energy-efficient way. Depending on their position, they allow the hydraulic fluid to flow faster or slower, which changes the characteristics of the dampers between a soft setting for long distance ride pliancy and a firmer footing for faster A and B-road driving.

Audi predictive active suspension