The new Volkswagen Arteon R-Line 4MOTION will soon be leaving the assembly plant in Pekan, Pahang. It is expected to be priced between RM245,000 and RM255,000 and Volkswagen Passenger Cars Malaysia (VPCM) is now accepting pre-bookings.

Introduced to the Malaysian market last year, the Arteon is Volkswagen’s flagship with the latest enhancements, including an updated interior and exterior, new technology and a new 2-litre engine.

The redesigned front grille and bumper are more prominent and complement the full LED headlights. At the rear, new LED 3D lights with sequential indicators add character to the Arteon’s sloping fastback design. It is also the first model to carry the new Volkswagen and R logos.

The Arteon is powered by a 2.0-litre TSI turbocharged petrol engine which produces up to 280 ps, with 350 Nm of torque. A 7-speed wet-clutch DSG is used to deliver the power which goes to all four wheels, thanks to the Volkswagen4MOTION all-wheel drive system.

Inside the Arteon R-Line 4MOTION, the cockpit area has a new steering wheel with haptic touch controls, and ErgoComfort sports seats in Nappa Carbon leather and 14-way adjustment. For the driver, a high-resolution Digital Cockpit offers convenience and the views can be easily customised.

The Discover Pro infotainment system, with a 9.2-inch colour display, comes with voice and gesture control for safer handsfree management of various functions. The system now supports both wireless App-Connect for Apple CarPlay and Android Auto, allowing favourite apps to be brought to the dashboard. Also standard is a premium Harman Kardon 700W audio system with 12 speakers strategically positioned around the cabin.

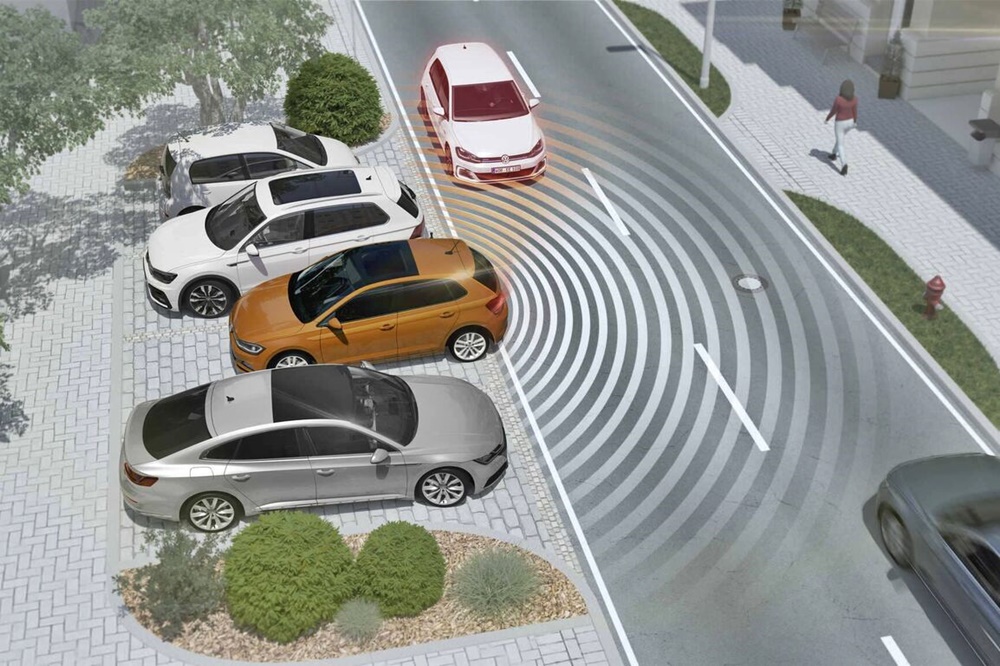

Like many modern cars, the Arteon R-Line has driver assistance systems which include Lane Assist, Side Assist, and an Automatic Post-Collision Brake System. It even reminds the driver to take a break on long journeys. A Surround View camera provides all-round coverage with a simulated image integrated to real imagery from small cameras around the bodywork.

As with all Volkswagens sold by authorised dealers in Malaysia, the Arteon R-Line 4MOTION comes with 3 years of free scheduled maintenance, 5 years warranty coverage with no mileage limit, and Roadside Assistance for the first 5 years of ownership.

Visit www.volkswagen.com.my to know more and to make a booking, you can use the eShowroom.

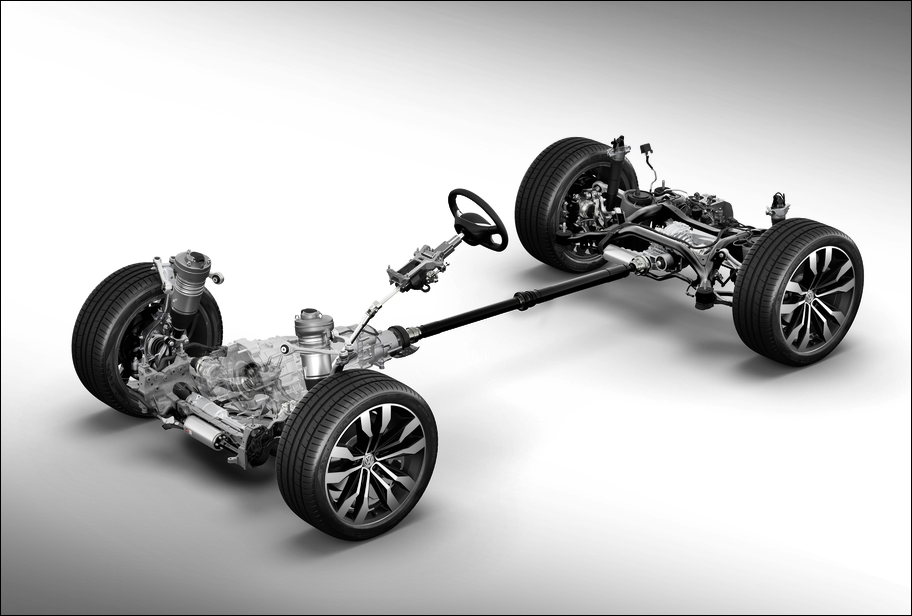

What is 4MOTION?

4Motion is Volkswagen’s all-wheel drive (AWD) system which delivers power to the front wheels as well as the rear wheels. While many people may think that AWD is only good for off-road driving, it is actually useful on the road too.

With all 4 wheels powered, traction is improved and this will be appreciated on wet or slippery roads. Acceleration can also be improved and grip during cornering is also better. Of course, the Laws of Physics still apply so having 4MOTION doesn’t mean that you can drive around a corner faster than the capability of the tyres to grip the road.

AWD systems like 4MOTION have ‘intelligence’, sending power to whichever wheel needs it at any given moment. If it senses a wheel starting to spin, the system cuts the power going to that wheel and sends more power to whichever of the other wheels can best use it. Because it all happens automatically, the driver can focus on driving.

The 4MOTION system in the Arteon R-Line is one of two versions which Volkswagen developed. In Arteon application, because the engine is mounted transversely, an electro-hydraulic Haldex coupling is used whereas the other version for models like the Touareg SUV employ a mechanical Torsen centre differential to distribute power to the front and rear wheels. This is because of the engine being installed in a longitudinal orientation.

Power delivery is on an infinitely variable basis by a multi-plate clutch. Normally, power is mainly transmitted to the front axle, which saves energy. However, in the event of an impending loss of traction, the rear axle is activated in a fraction of a second. The distribution of power to all four wheels becomes active before wheelspin occurs, rather than being reactive. A loss of traction is therefore virtually excluded. However, should any wheel slip occur, power is immediately transmitted to the wheels where it is needed.