BMW Malaysia tonight introduced the M8 Coupe (F92) and M8 Gran Coupe (F93) as the newest high-powered members of its portfolio. Priced RM1,452,960.88 and RM1,455,145.25, respectively, the new BMW models are with a choice of seven colours: Alpine White, Brands Hatch Grey, Marina Bay Blue, Motegi Red, Black Sapphire, Donington Grey and Barcelona Blue. The interiors come with Merino Leather, in either Black or Silverstone.

Optionally, BMW Individual is available for owners to personalise their cars. For those who cannot wait, one unit of the M8 Coupe in BMW Individual Frozen Bluestone exterior is available for purchase immediately (at an additional RM30,000).

Both new models are available at authorised BMW dealerships nationwide from today. If you are convinced one of these cars is for you, go straight to the BMW Online Shop at www.shop bmw.com.my where you can place your booking for RM5,000.And who knows, you might also get to win a new BMW i8 Coupe.

With the Balloon Financing Plan from BMW Group Financial Services Malaysia, the M8 Coupe and M8 Gran Coupe can be owned with monthly instalment plans starting from RM16,578 and RM16,598, respectively (terms and conditions applicable).

New frontal design language

The two models present the newly introduced 8-Series design language with muscular sculpted surfaces and distinctive characteristics at the front. These include the new M-specific front apron, along with the BMW kidney grille featuring M-specific decorative mesh, double slats and M8 designation.

The slender BMW Laserlights with high-beam assistant are positioned slightly higher than the kidney grille, widening towards the road to emphasise the low-slung stance and low centre of gravity.

Both exterior mirrors have the characteristic M twin-stalk design and in typical fashion of BMW coupes, there are frameless side windows with BMW Individual high-gloss Shadow Line. Flared aluminium wings with M gills and M8 designation emphasise track width and wheel size.

Towards the rear, both models sport the M rear spoiler, as well as M-specific M8 rear diffuser and M-specific exhaust system with twin tailpipes and chrome trims.

Other highlights of the two-door M8 Coupe and four-door M8 Gran Coupe include the soft-close function for doors and carbon roof made of self-coloured carbonfibre reinforced plastic (CFRP) that saves weight and lowers the centre of gravity. 20-inch M light alloy wheels in Double-spoke style 810 M Bicolour with mixed tyres are fitted.

Most powerful BMW M engine

Both cars have the same powerplant under the long bonnet: the completely redesigned high-revving S63 V8 engine with M TwinPower Turbo technology. This 4.4-litre unit is the most powerful BMW M engine ever built for a production model, generating up to 600 bhp/750 Nm. That gives a 0 to 100 km/h capability claimed to be 3.3 seconds and a top speed beyond 250 km/h but not attainable since the maximum speed is electronically limited.

The engine’s characteristics can be personalised in one of three modes – the default EFFICIENT setting, SPORT or SPORT PLUS. Depending on the mode selected, the system will change the response to accelerator pedal pressure as well as the sound characteristics of the flap-controlled exhaust system. A Sound Control button next to the gear selector lever is available for drivers wanting to adjust the sound from the M exhaust system according to their personal preferences.

Power flows through a new 8-speed M Steptronic transmission with Drivelogic, operated sequentially via an M8-specific gear selector in S mode, or manually via paddles on the steering wheel.

Driving dynamics are enhanced with the M xDrive all-wheel drive system that has rear-wheel bias. For skilled and experienced drivers, the fully variable torque split can be adapted to personal preferences. The 4WD default setting can be switched to 4WD Sport and, with the DSC switched off, a rear-wheel-drive-only 2WD mode can be used on the track.

The models are also fitted with the M-specific integrated brake system. This innovative technology combines brake activation, brake booster and braking control functions in one compact module. The required brake pressure is established by an electric actuator, optimising braking dynamics and pedal feel as well as the precision and speed of DSC stability control interventions.

Sporty cockpit

As would be expected, the cockpit of both models has a sporty, low seating position with controls grouped into clusters according to their function. The M Sport seats, with illuminated M logo, come with many electric adjustment options including a Memory function.

The rear seats – upholstered in Merino leather as standard – are moulded to provide maximum lateral support which will be appreciated during ‘dynamic’ driving. With the rear backrests folded, the coupe has 420 litres of cargo space in the boot while the Gran Coupe has another 20 litres more.

For infotainment, there’s the BMW Live Cockpit Professional running on the BMW Operating System 7.0. This package consists of an all-digital 12.3-inch instrument cluster, a high-resolution 10.25-inch Control Display and a full-colour Head-Up Display with additional M-specific displays.

Both models can be operated via the BMW Intelligent Personal Assistant’s latest voice control system, direct menu control buttons, the intuitive iDrive Touch Controller with its rotary/push button, the touchscreen Control Display or the Gesture Control system.

The new M Mode selector on the centre console can be used to control the driver assistance systems as well as the content of the instrument cluster displays and the Head-Up Display. M Mode can be used to activate the ROAD and SPORT settings and in addition to the M Mode selector, the BMW Intelligent Personal Assistant enables drivers to use their normal, natural voice and speech pattern to interact with the vehicle.

BMW ConnectedDrive provides Connected Package Professional such as Remote Services, Teleservices, Intelligent Emergency Call, Apple CarPlay and Concierge Service. Other highlights include the Digital Key to unlock, start and lock the car using a compatible Samsung smartphone (available as part of the Comfort Access).

Limited-Time, Special Programmes

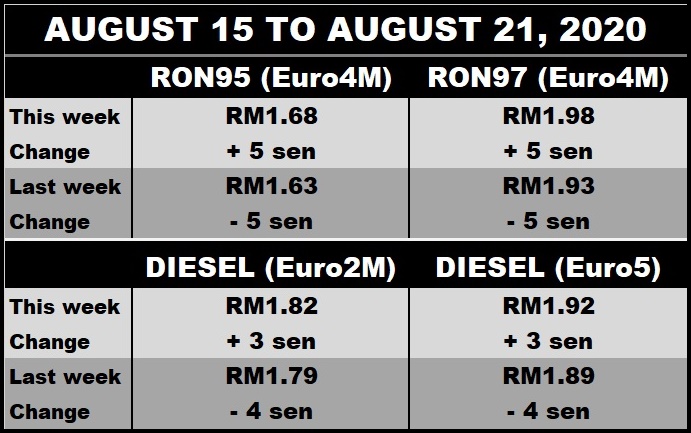

From August 15 to September 30, 2020, BMW Group Malaysia is offering special programmes and campaigns for a range of BMW M models. The Limited-Time M Town Special Support offers new owners of the M2 Competition, M4 Coupe, M5 Sedan, M850i xDrive Coupe an attractive price reduction of RM25,000, RM45,000, RM70,000 and RM75,000, respectively.

BMW and MINI owners can now enjoy Door-to-Door Service