The Nissan Serena S-HYBRID was among the first hybrid models to be assembled in Malaysia and up till today, it is still the only locally-assembled hybrid MPV. With this generation of the Serena, not only did Nissan give it a hybrid powertrain but it also upgraded the MPV to be a more premium product. It offers the luxuries that many enjoy in other up-market MPVs for a lot less.

Cosmetic changes up front

Periodically, Edaran Tan Chong Motor (ETCM) refreshes its models and adds a bit more value, and for 2022, the Serena gets cosmetic changes in the form of redesigned headlamps with daytime running lights, a new V-motion front grille with a distinctive chrome pattern, redesigned front bumper with foglamps.

Besides the cosmetic changes, the Serena S-HYBRID maintains practical and thoughtful convenience features such as a two-section back door and hands-free powered sliding doors on both sides, as shown below.

Versatile interior

The spacious and versatile interior has as many as 13 seating layouts with Captain Seats on the second row. These have individual armrests and extra-long slide adjustment. Front passengers and those in the second row have Zero Gravity Seats, inspired by NASA’s studies in achieving the most neutral posture for fatigue-reduction. Quality materials are used, such as combination Nappa leather for the seats. And there are no less than 7 USB ports so there are unlikely to be any fights over who gets to recharge first!

Nissan Intelligent Mobility (NIM)

With its 7-passenger capacity, safety is even more important and Nissan Intelligent Mobility (NIM) provides a suite of advanced technologies with both Active Safety and Passive Safety systems. Five smart intelligent technologies have been added to the new Serena S-HYBRID to enhance Active Safety – Intelligent Predictive Forward Collision Warning, Intelligent Forward Collision Braking, Lane Departure Warning, Blind Spot Warning and Rear Cross Traffic Alert.

The Around View Monitor (360o camera) is also standard and gives the driver situational awareness around the vehicle. It uses four tiny cameras to capture images which are then combined to give an overhead view as if a drone was permanently hovering and sending imagery. The system also has Intelligent Moving Object Detection which will detect and alert the driver of moving objects – especially pedestrians – around the vehicle.

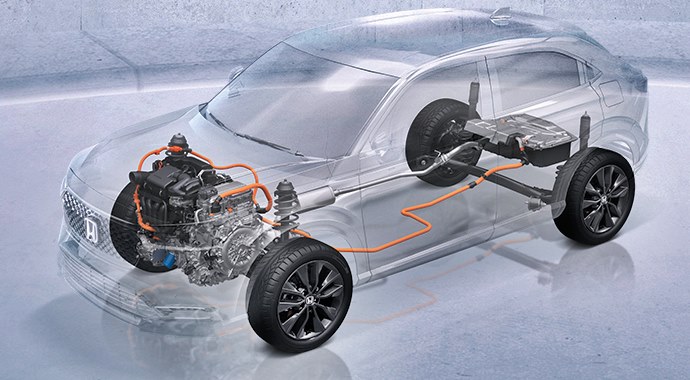

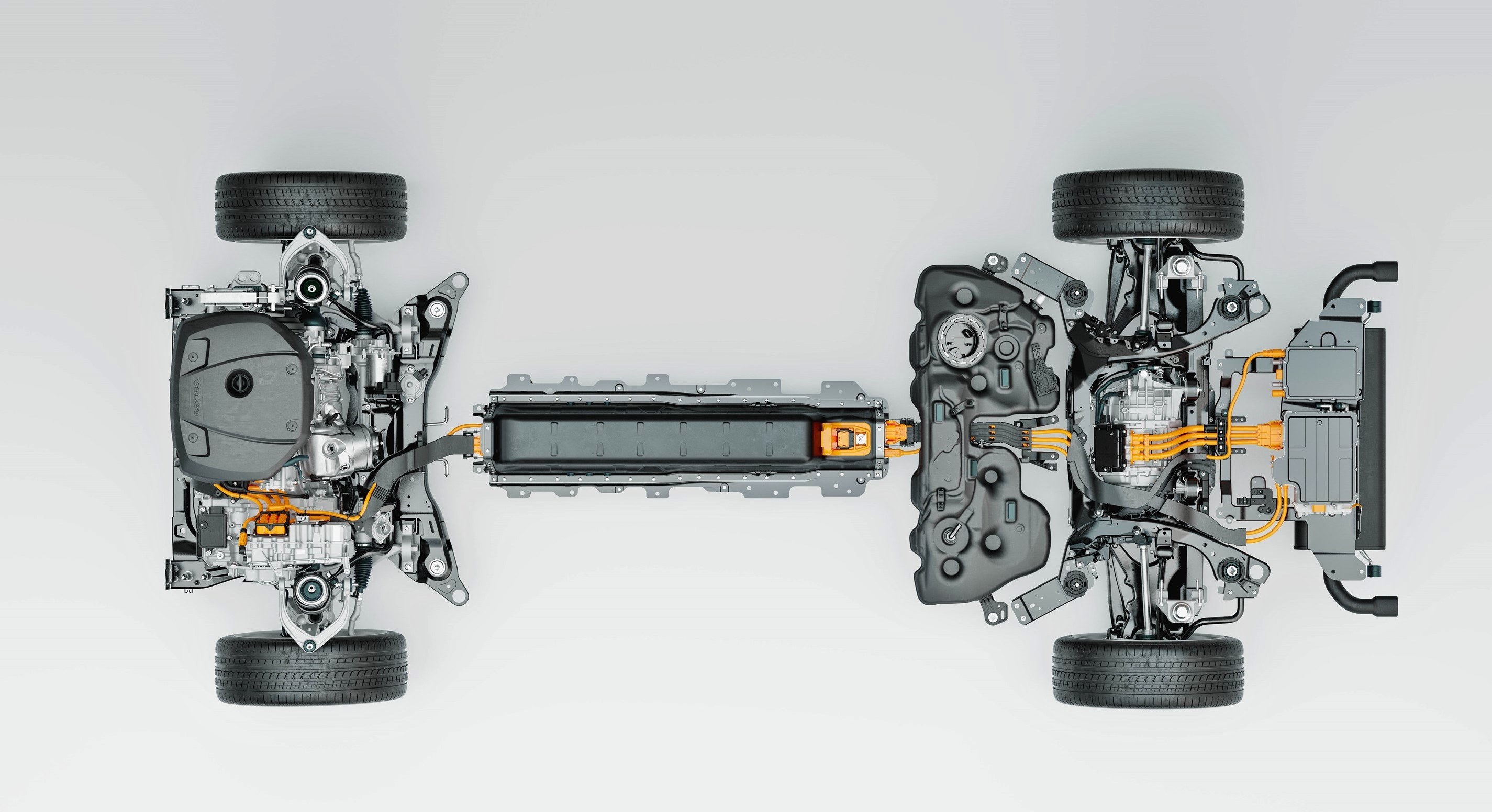

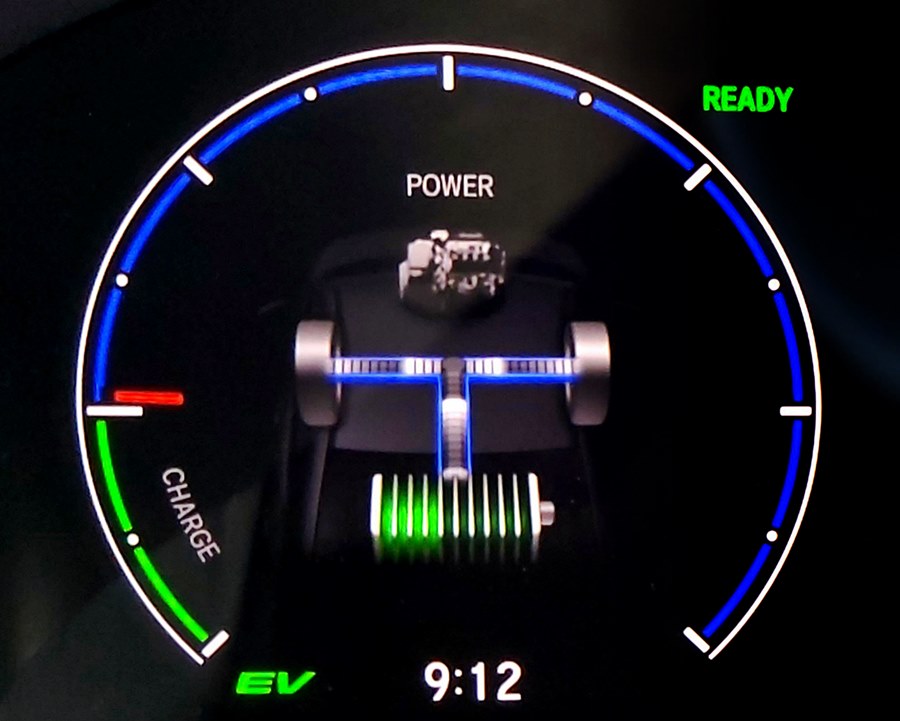

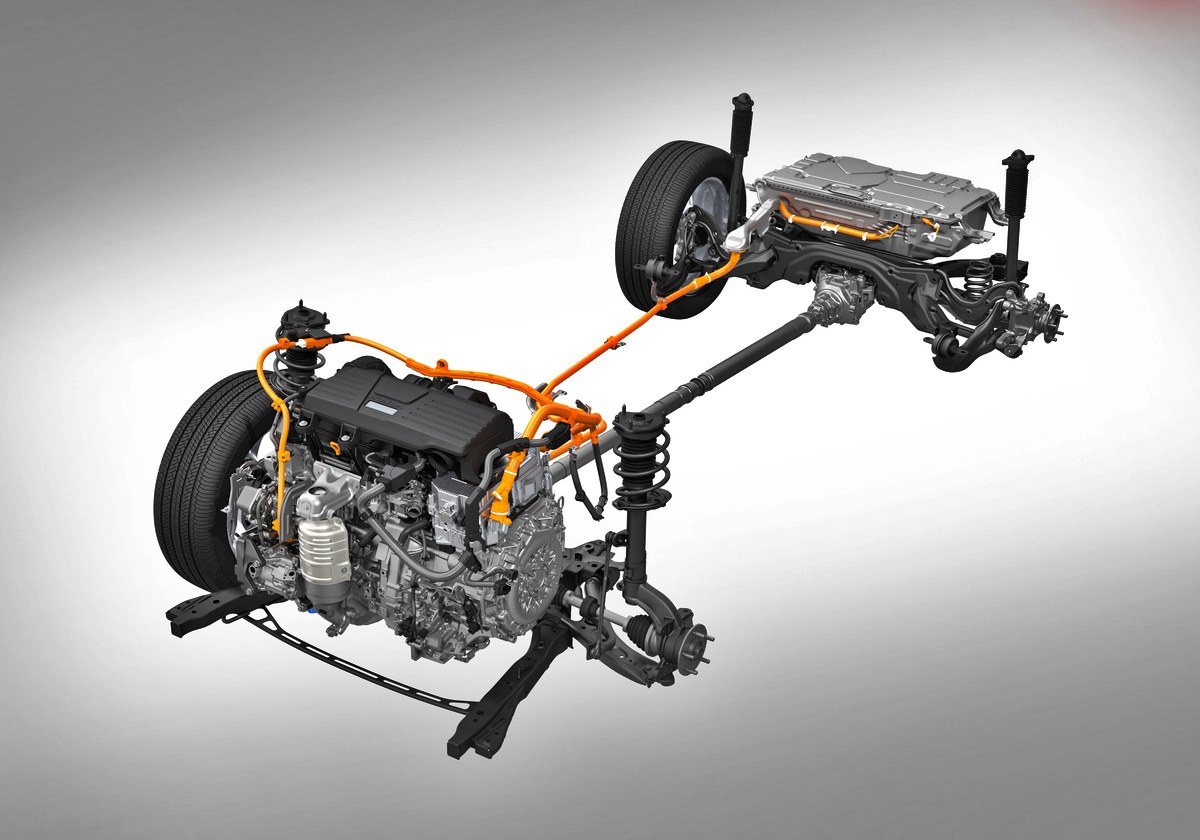

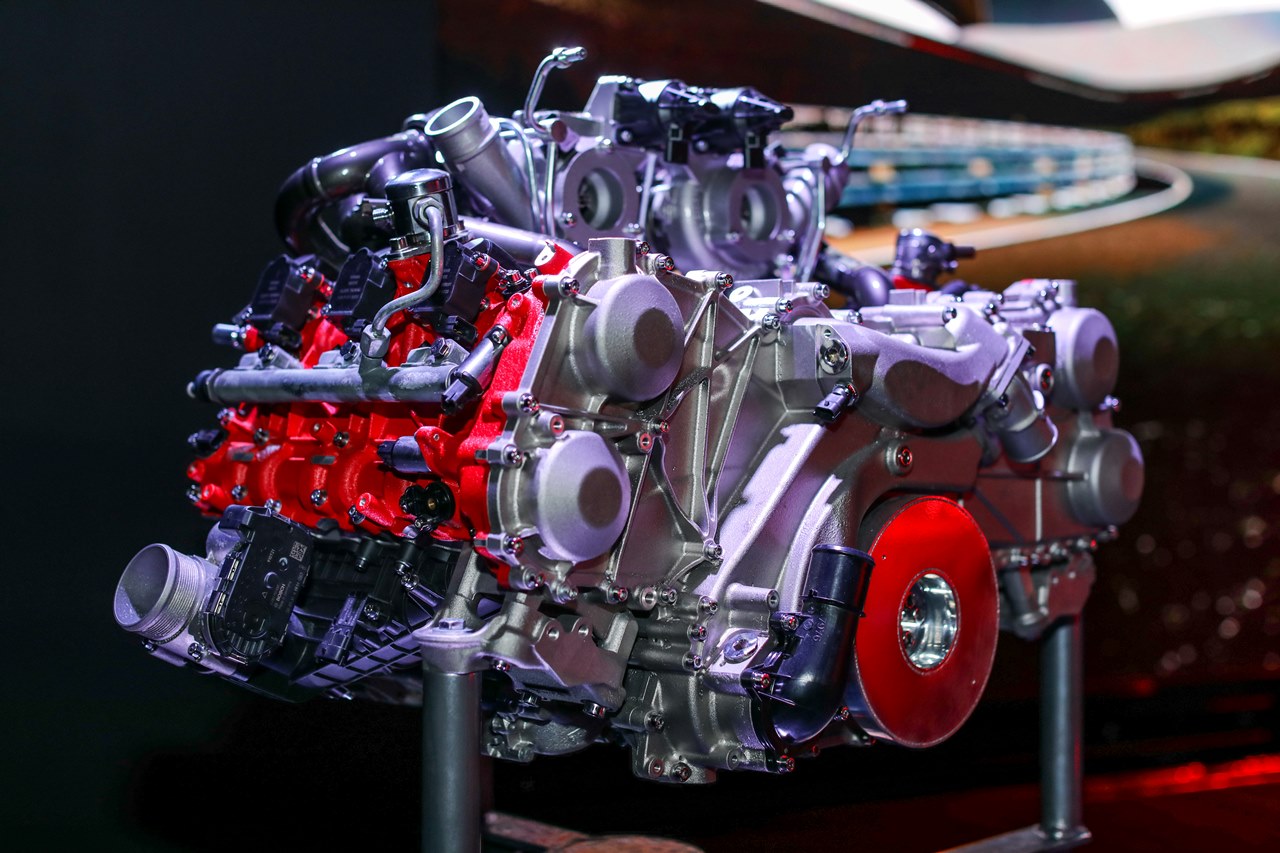

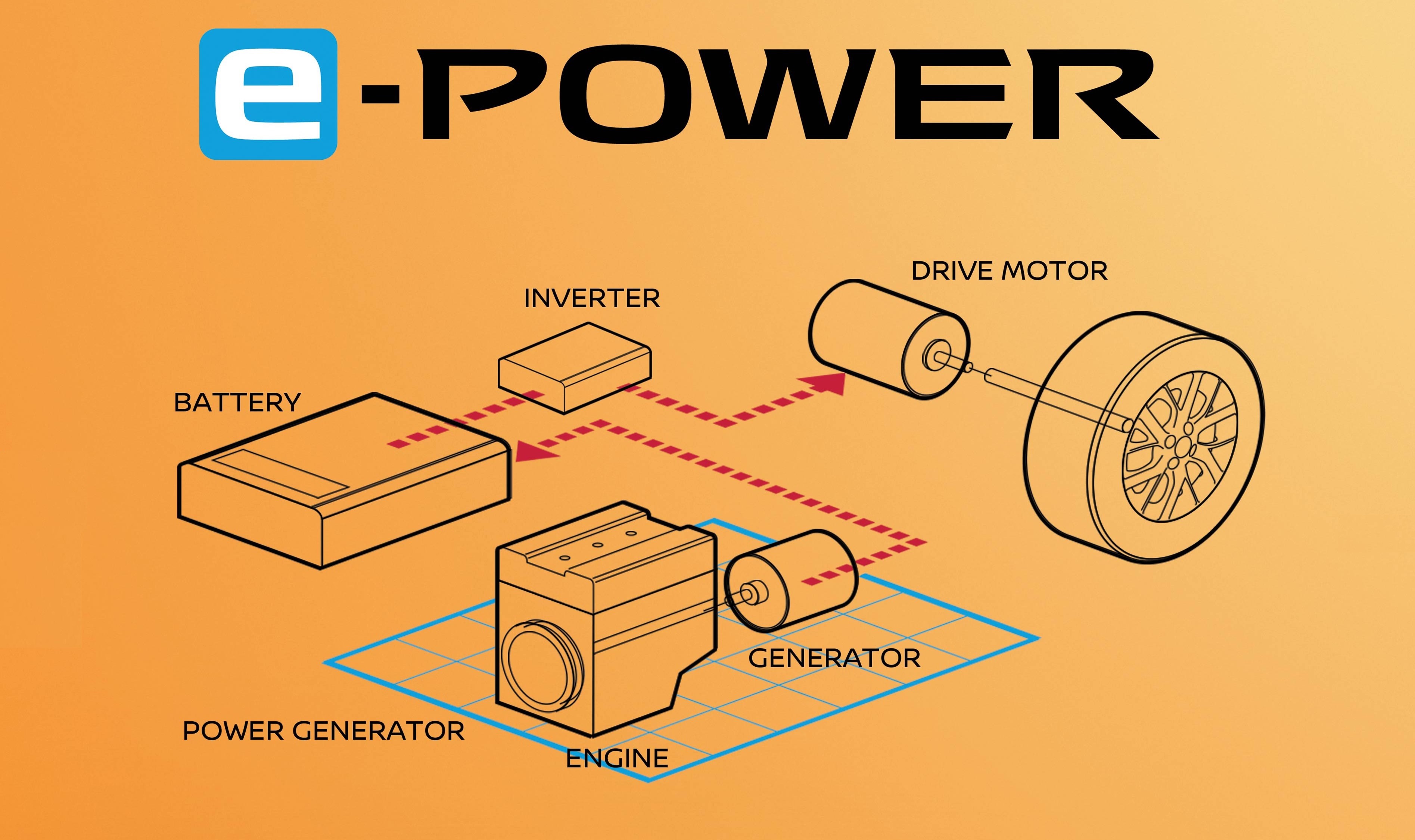

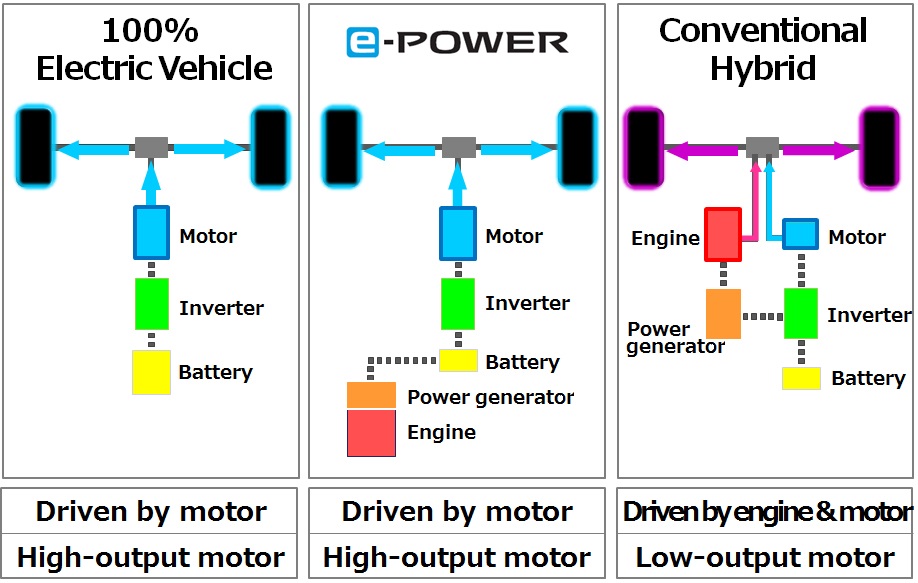

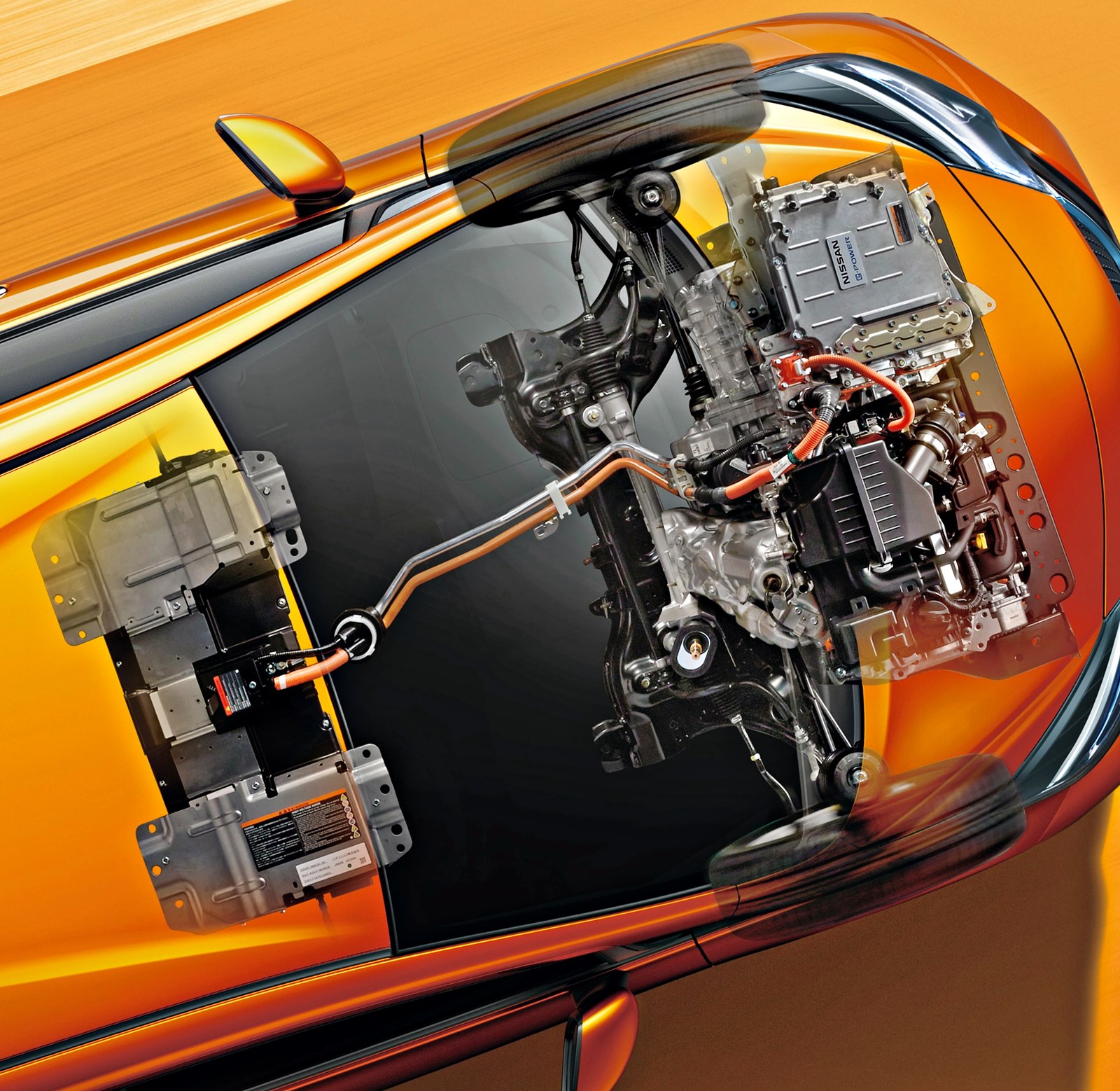

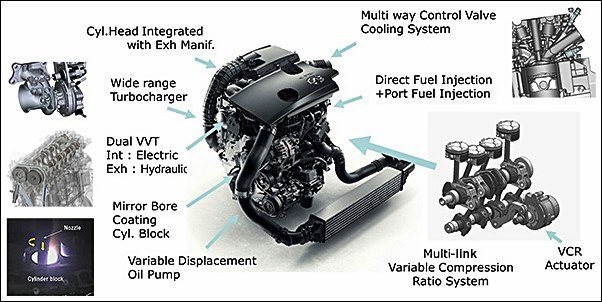

S-HYBRID system

The Serena S-HYBRID continues to be powered by the proven 2-litre Twin CVTC hybrid drivetrain. Its ECO (Energy Control Motor) electric motor provides torque assistance on take-off, reducing demands on the petrol engine, thereby improving fuel efficiency. This gives some of the benefits of a hybrid powertrain without the associated high costs.

Two variants are available, with estimated prices starting from less than RM150,000 for the Serena S-Hybrid Highway Star and from less than RM165,000 for the Serena S-Hybrid Premium Highway Star. The prices are for Peninsular Malaysia registration and include full sales tax but not insurance

While the model will have its launch in early July, bookings are now accepted at all authorised Nissan showrooms nationwide. ETCM encourages customers to make their booking early (minimum amount of RM1,000) to secure a unit in the system. It will also help the assembly plant to schedule production more accurately and minimize waiting time as disruptions continue due to semiconductor microprocessor shortages and global shipment delays. Depending on the variants, there are up to four colour choices.

‘Early Bird’ offer

For the ‘early birds’ making bookings, ETCM has a special offer to save money when they are owners. Five free maintenance services (inclusive of parts & labour) will be provided at alternate intervals (10,000 kms, 30,000 kms, 50,000 kms, 70,000 kms and 90,000 kms), and the warranty period will also be up to 5 years with unlimited mileage (terms and conditions apply).

Customers who require more information or locate a showroom can visit the Nissan Malaysia website at www.nissan.com.my. They can also contact the Nissan Customer Care Centre hotline at 1800-88-3838. A pre-launch leaflet is also available by clicking here.

Click here for other news and articles on Nissan and ETCM,