Building on the successful Pilot Sport 4 tyre, Michelin today launched the new Pilot Sport 5 in Asia and Australia today. For markets in Asia, the fifth generation of the popular high-performance tyres will be offered in up to 43 sizes for 17-inch to 21-inch wheels. The Malaysian market will have 26 sizes from 17 to 19 inches, with 21 more sizes from 17 to 21 inches to be made available by the end of this year. The recommended retail prices of the new tyres range from RM700 to RM1,900.

Sophisticated features

Targets at sportscar and high-performance sedan drivers, the new Pilot Sport 5 has a range of sophisticated features and is, of course, improved in performance over its predecessor. The key features include Dual Sport Tread Design technology, Groove Clear, Dynamic Response technology, MaxTouch Construction, and Premium Touch Sidewall Design.

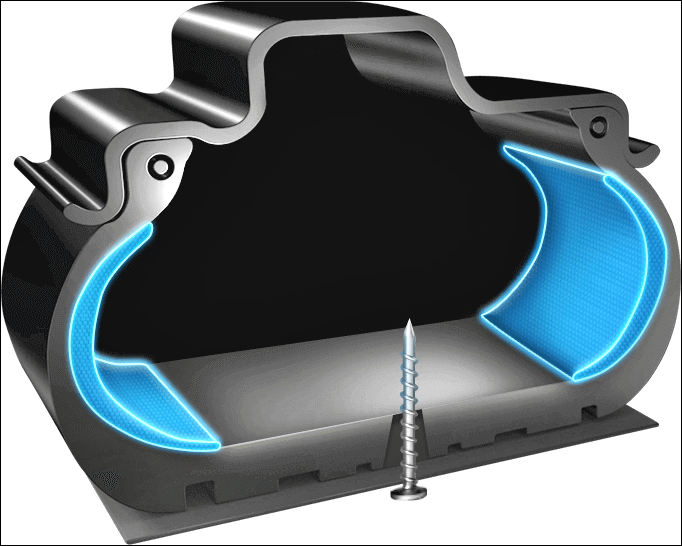

Dual Sport Tread Design technology is like having two tyres in one as there is a two-sided functionalized tread design inspired by Michelin’s motorsport experience. On the inner side of the tyre is a tread pattern with large grooves and high void ratio for enhanced wet road traction, while the outer has rigid blocks for better grip on dry roads. Groove Clear is the association of large longitudinal grooves that guide water under the tyre into wide transversal channels from which the water is ejected to keep the contact patch as dry as possible.

Shorter stopping distances

Independent testing showed that on a wet road, the Pilot Sport 5 stopped 1.4 metres (new tyres) and 4 metres (worn tyres) shorter than other premium brands. On a dry road, the stopping distance was 1.3 metres shorter. Other testing also showed that the Pilot Sport 5 lasted 33.5% longer than tyres from other premium brands. This longevity is due to the MaxTouch Construction that maximizes the tyre’s contact with the road and evenly distributes the forces of acceleration, braking, and cornering without sacrificing performance.

Lasting performance

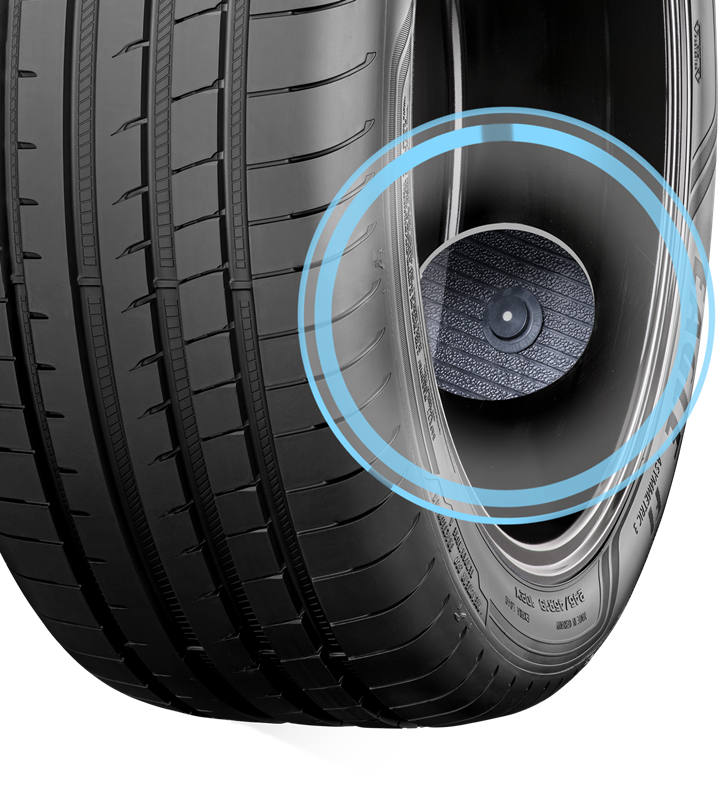

Michelin also makes sure that its tyres provide lasting performance throughout the lifespan. This is made possible by Dynamic Response technology that uses a high-density aramid and nylon hybrid belt which promotes driving precision for optimum transmission of steering instructions onto the road. This belt, which is located just below the tread, is both very resistant and light. Thus, at equivalent weight, the associated nylon and aramid are 5 times more resistant than steel.

The tread pattern usually gives character to a tyre but for the Pilot Sport 5, the sidewall too has been given sporty and appealing aesthetics. Michelin’s patented velvet sidewall branding, called Premium Touch Design has a matte-black velvet-like micro texture which gives a premium look and feel.

Drivers who care for their tyres and for safety will regularly check on the tread wear (besides the pressures). To make it easier, Michelin has added Wear2Check, an easy-to-find and easy-to-read tread wear indicator (TWI) on each tyre. This is visible by three tiny holes on certain tread blocks, indicating the area where the TWI is running across.

“With the Michelin Pilot Sport 5, Michelin further strengthens our complete and best overall high-performance Pilot Sport range, with ‘Performance Made to Last’ being our key differentiator. Inspired by motorsports, the tyre is perfect for drivers who demand sporty driving performance and expect nothing but the best. What’s more, the Michelin Pilot Sport 5 goes one step further in aesthetics, as evidenced by its 2021 Contemporary Good Design Award – one of the world’s most prestigious international design awards,” said Michelin Malaysia’s Managing Director, Oliver Biggart.

Michelin Malaysia introduces BFGoodrich Trail-Terrain T/A tyre for SUVs and pick-up trucks