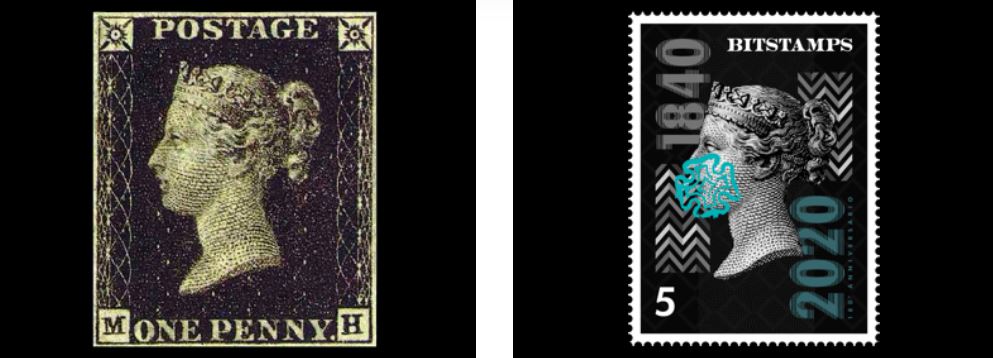

Everything is going digital these days and collecting stamps seems to be following the trend. Lamborghini, together with Bitstamps, is launching a digital stamp via an App designed to create and collect digital stamps. Each stamp is a ‘single’ digital object: its history and uniqueness are guaranteed by Blockchain technology. The stamp can be purchased, collected, or resold exactly like a paper stamp.

First Lamborghini digital stamp

The first collaboration is dedicated to the Huracan EVO RWD Spyder, a new model Lamborghini unveiled at the beginning of this month, following the company’s reopening after the COVID-19 shutdown. The Huracan EVO RWD Spyder stamp is available from today by downloading the Bitstamps App, and will be issued in a limited and numbered edition of 20,000 pieces.

The stamp is part of a themed series dedicated to the history of the Italian sportscar maker. Over 20 of its most iconic cars will form the Automobili Lamborghini Collection.

Within their collection album, Lamborghini fans will be able to admire their stamps, check the progress of their collection and the stamps not yet acquired, decide whether to give them as a gift by sending them with an e-card, or resell them on the Marketplace that will open in the next few months.

About Bitstamps

Working for a long time in the philatelic field, it was not difficult for Nicola Archilli, the CEO of Bitstamps, to notice how the trade in stamps evolved from negotiations in niches to specialized stores, to auction houses and subsequently to web sales. Specialized platforms now have millions of specimens on offer and the market is very dynamic, even if not referred to the rarest and most expensive specimens.

In the digital collectibles sector, there are innumerable types of products offered ranging from clothes for virtual dolls to plots of land where you can build digital cities, but what made him think a lot and land with confidence on the digital stamp was the choice of the largest producer American baseball players card.

In April 2012, the company came out with a new app through which it is possible to buy the digital cards of baseball players. This diversification of the product has led the company, which still continues to print paper cards, to double its turnover by dividing it more or less equally in the two sectors. The new product was a success without going to the detriment of the paper ‘competitor’ and allowed a strong expansion

The Bitstamps App can be downloaded at Google Play and Apple App stores.

Lamborghini debuts Huracan EVO RWD Spyder using Augmented Reality

All authorised Honda dealerships throughout Malaysia are now fully operational with regards to both showrooms and service centres. Earlier, only service centres had been permitted to resume operations but under the less restrictive Conditional Movement Control Order (CMCO), the full range of services can now be provided. However, areas such as children’s play area and cafes will remain closed.

Adhering to the Health Ministry’s Standard Operating Procedures (SOPs), all dealerships will conduct temperature screening for customers and require the use of hand sanitizers (to be available at the facilities). Individuals recording temperature of 37.5 degrees C. and above or are exhibiting symptoms of fever, cough and shortness of breath will be advised to leave the premises to immediately seek medical attention.

The customer flow at all dealerships has been arranged to have only one entrance and one exit for a more effective check-and-control measure. High traffic or frequently used areas such as the door handles and washrooms are sanitized and disinfected on a regular basis every day. Upon entrance into the showroom, face masks will be provided to the customers. Both customers and Honda sales advisors are required to wear face masks before engaging in any discussion.

All display cars in the Honda dealerships will be cleaned using certified sanitisers regularly every day. Sales advisors are required to adhere to the recommended social distance of 1 metre from customers during the explanation on the exterior of the Honda models. During the demonstration and explanation of interior features of the car, the sales advisors will sit in the rear seat to maintain social distancing at all times.

The same practices will apply during test-drives, with gloves also being provided for use by customers, with the vehicles being sanitized before and after each test drive session, with particular attention to the areas and accessories that are frequently touched. Honda Malaysia encourages the use of contactless payments using electronic transfers.

With regards to hand-over of new vehicles to customers, Honda Malaysia says that in view of the current situation, customers are advised to limit the number of people present to ONE person to avoid having a large crowd in the showroom.

As reported earlier, customers requiring aftersales services must make an appointment first. The number of customers present at any one time for vehicle service in the dealership is limited at minimum capacity.

For those concerned about their vehicle warranties, the company has made special considerations in view of the restrictions caused by the MCO. Warranties which expired between March 18 and May 12, 2020 are extended until June 11, 2020. Scheduled servicing which was required between March 18 and May 12, 2020 can be done before July 11, 2020.

“Even as our dealers commence operations in full, we will continue to emphasise customers and associates’ safety by practising social distancing as well as following the safety practices and guidelines. We have implemented strict precautions for everyone’s wellbeing,” said Honda Malaysia’s Managing Director & CEO, Toichi Ishiyama.

“Honda Malaysia emphasises that the company is monitoring the development of the situation in the nation closely and working hard to ensure a safe environment in all its operations including dealerships to provide customers with peace of mind when visiting a Honda dealership,” he added.

In recent years, as the popularity of SUVs (especially the smaller ones) increased, many importers have focussed more on variants with only 2WD. These are usually cheaper, and customers don’t really care about whether two or all four wheels are powered. They’re more interested in the high seating position and perhaps the ground clearance, as well as interior utility.

However, there are also those who feel that 4WD or All-Wheel Drive (AWD) should be present in SUVs, just like they were in earlier years. Never mind that they might not actually go off-road, the presence of AWD added a degree of stability and grip, especially on wet roads.

When Bermaz Auto introduced the Mazda CX-30 at the beginning of this year, it offered only FWD versions with either SKYACTIV petrol or turbodiesel engines. Now, the range will include an AWD variant which is priced at RM176,059 (Peninsular Malaysia price, without insurance) for those who must have all four wheels powered.

The price is RM12,000 more than the high grade CX-30 which has the same 2-litre SKYACTIV-G petrol engine. This is not surprising since the i-ACTIV AWD system, which is quite sophisticated, adds cost, apart from the fact that the CX-30 is imported from Japan as a CBU (completely built-up) model.

The features and specs are the same as the CX-30 High Grade and you have a choice of 8 exterior colours – Soul Red Crystal, Machine Gray, Jet Black, Deep Crystal Blue, Sonic Silver, Snowflake White Pearl, Titanium Flash and Polymetal Gray Metallic.

How Mazda i-ACTIV works

The AWD systems in today’s SUVs vary in sophistication and for Mazda’s i-ACTIV AWD system, the engineers redesigned the system’s hardware and software, taking a proactive approach to controlling drive to all four wheels,

A fully-autonomous AWD system, i-ACTIV AWD constantly monitors surface conditions in real-time, watching for tiny variations in wheel speed that a driver would never notice. Proactively controlling the distribution of torque, which can range from full front-drive through to full 4-wheel-drive, the system not only provides solid and predictable handling for all-road performance, it makes driving on poor road surfaces more efficient by all but eliminating wasteful tyre-slippage.

Using a wide range of sensors to ‘paint’ a highly accurate picture of the overall driving scene, including road conditions and the driver’s intentions, i-ACTIV continuously calculates and adjusts the amount of torque sent to the rear wheels.

The perfect amount of torque is calculated and transferred to the rear wheels instantaneously (as and when needed). This is done by the AWD coupling unit which sends the appropriate drive force to the rear wheels. The system minimizes torque to the rear wheels when on dry road surfaces with good traction. The result is secure take-off, acceleration, cornering and braking, without the tyres slipping in any direction.

The sensors monitor for rain by watching the wipers and the external temperature gauge. The system can also measure how slippery the road surface is by comparing steering torque with the amount of current running through the electric power steering and the gradient of any slope by the degree of acceleration. In addition, the system precisely measures the speed of all four wheels and detects warning signs that indicate the wheels may be in danger of slipping. Along with engine driving force (applied to the front wheels), this is used to understand the driving conditions.

The i-Activ AWD system also has an Off-road Traction Assist system. The system works by distributing the driving force to the tyres that are in contact with the road surface to maximize traction performance.

Additionally, a Torque Control System that allows a lag-free, near-instantaneous response. In order to help the rear-wheel drive unit respond more quickly, the Torque Control System transfers a very small amount of torque to the rear even in front-wheel drive mode. This is known as ‘stand-by torque’ and it helps the system make a smooth and instantaneous transition to AWD drive mode when the command is received to send torque to the rear wheels.

Proven SKYACTIV-G powertrain

As for the powertrain, this uses the proven SKYACTIV-G Direct Injection petrol engine. For the CX-30, the displacement is 1998 cc with a maximum output of 162 ps/213 Nm. Mazda engineers have been able to raise the compression ratio of 13:1 to enhance output without knocking issues even when using RON95 petrol.

Only a SKYACTIV-DRIVE automatic transmission is available but using paddle shifters, the driver can also manually select any of the 6 forward speeds if preferred. While the driver can get sportier performance with a SPORT mode, the AWD system operates entirely on its own with no need for driver involvement.

Extras for the base version

With the latest shipment of CX-30 2.0G version, Bermaz Auto has included a couple of new features – Mazda Advanced Keyless entry and Walk-Away Lock – for added convenience. Though priced at RM145,759 or RM18,300 less than the High Grade version, this version still has a very comprehensive list of equipment and features that justify the price. And as we noted during a test-drive, the CX-30 also has high quality in every aspect which gives a very premium image.

Visit www.mazda.com.my to know more about the CX-30 and other Mazda models in Malaysia.

Aerodynamics are one of the crucial elements in achieving high performance. Designers and engineers spend thousands of hours running simulations and then testing prototypes in wind tunnels to get the air to flow optimally around the bodywork.

This is the work of Richard Hill as chief aerodynamicist at Lotus Cars, where he has been for more than 30 years. Drawing on his experience and knowledge, the highly experienced senior engineer guided this critical element of the Evija all-electric hypercar to give phenomenal downforce. When asked how the Evija compares to regular sportscars, he replied: “It’s like comparing a fighter jet to a child’s kite.’’

The overall philosophy behind the Evija’s aerodynamics is about keeping the airflow low and flat at the front and guiding it through the body to emerge high at the rear. Put simply, it transforms the whole car into an inverted wing to produce that all-important dynamic downforce.

“Most cars have to punch a hole in the air, to get through using brute force, but the Evija is unique because of its porosity. The car literally ‘breathes’ the air. The front acts like a mouth; it ingests the air, sucks every kilogram of value from it – in this case, the downforce – then exhales it through that dramatic rear end,” explained Hill.

And what role does that deep front splitter play? According to Hill, it’s designed in three sections: the larger central area provides air to cool the battery pack – which is mid-mounted behind the two seats – while the air channelled through the two smaller outer sections cools the front e-axle.

“The splitter minimises the amount of air allowed under the vehicle, thus reducing drag and lift on the underbody. It also provides something for the difference in pressure between the upper and lower splitter surfaces to push down on, so generating downforce.,” he said.

Venturi tunnels through the rear quarters are part of the porosity. They feed the wake rearward to help cut drag. “Think of it this way – without them, the Evija would be like a parachute but with them, it’s a butterfly net, and they make the car unique in the hypercar world,” the engineer explained.

To have active aerodynamics, the Evija’s rear wing elevates from its resting position flush to the upper bodywork. It’s deployed into ‘clean’ air above the car, creating further downforce at the rear wheels. The car also has an F1-style Drag Reduction System (DRS), which is a horizontal plane mounted centrally at the rear, and deploying it make the car faster.

Lotus pioneered the full carbonfibre chassis in Formula 1, and the Evija is the first Lotus road car to use that technology. The chassis a single piece of moulded carbonfibre for exceptional strength, rigidity and safety. The underside is sculpted to force the airflow through the rear diffuser and into the Evija’s wake, causing an ‘upwash’ and the car’s phenomenal level of downforce.

The Evija is set to be the world’s lightest EV hypercar but weight does not actually affect aerodynamic performance. Hill said that the car’s weight has no effect on overall aerodynamics. However, the lighter the car, the larger the percentage of overall grip is achieved through downforce and the lower the inertia of the car to change direction.

Richard Hill’s full title is Chief Engineer of Aerodynamics and Thermal Management, and he has worked at the company’s Hethel HQ since 1986. His role involves collaborating with the exterior designers of all new Lotus vehicles, from the early concept phase of a programme through to testing pre-production prototypes.

The authorised Nissan showroom and service centre network in Malaysia is now fully operational, following closure due to the earlier Movement Control Order. With the revision to the Conditional Movement Control Order (CMCO), many businesses, including those in the auto industry have been allowed to resume their operations.

Edaran Tan Chong Motor (ETCM) says that while all their outlets have reopened, there are revised operating hours. The hours of operation for each outlet can be found at www.nissan.com.my or www.tceas.com (for service outlets).

SOPs at outlets

In line with the CMCO standard operating procedures (SOPs), the outlets will conduct temperature checks for all staff and customers and require social distancing as well. All staff will wear face masks, and customers can also obtain face masks, gloves and hand sanitizers at no charge while they are on the premises.

Frequent disinfecting will be carried out at the showrooms and service centres throughout the day covering every touchpoint including display and test drive vehicles. Customers are also assured that their vehicles will be disinfected before and after service. During this period, ETCM encourages contactless payments to be used.

Additionally, all vehicle registrations and deliveries will resume progressively as JPJ has started providing the necessary services since yesterday.

New Nissan Online Showroom

Those who are unable to visit Nissan showrooms can also get comprehensive information at the Nissan Online Showroom, also at www.nissan.com.my. The website enables interested customers to submit an online form for sales enquiries and to request appointments for testdrives at their home or office.

For those who are planning to buy a new Nissan vehicle for Hari Raya, the company has various money-saving promotions. Monthly instalments start from RM800 for models like the Almera while selected models come free scheduled maintenance for the first two years (terms and conditions apply).

Additionally, customers who purchase the X-Trail or Serena S-Hybrid before June 30, 2020, will receive a complimentary 1-year FWD Protect Direct Family Takaful protection plan (up to a family of 4 parents and 2 children) with a sum insured of RM100,000.

Currently, ETCM is running the ‘Nissan Buy & Win’ contest and 20 lucky winners will stand a chance to win CUCKOO Healthy Home Appliances worth up to RM128,888. The contest is on until June 30, 2020.

Use the new Nissan Online Showroom to start your purchase process today