BMW is taking a significant step in its electric vehicle (EV) lineup, and recent trademark applications suggest that the nomenclature for its forthcoming EVs will maintain simplicity. Notably, the electric 5 Series will adopt the straightforward moniker of the i5. Now, BMW is gearing up for the release of an electric M3, with a trademark application filed for the name “iM3” in Germany.

While BMW had the option to follow its high-performance SUV naming convention, such as using “i3 M,” it appears the company is leaning towards the iM3 designation. Despite the potential pronunciation quirk in English, where it sounds like “I am three,” BMW has a history of unique nomenclature, evident in models like the i8.

BMW’s M division has been vocal about its commitment to electrification. It’s important to note that while the i4 M50 exists in the lineup, it falls under the M Performance category, not a full-fledged M Car.

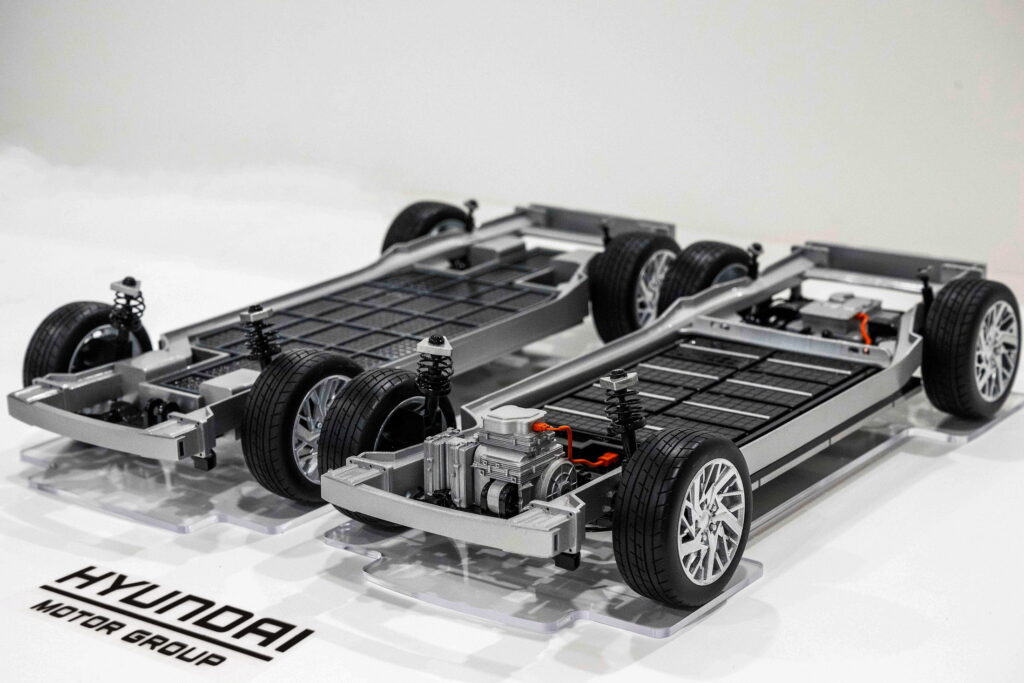

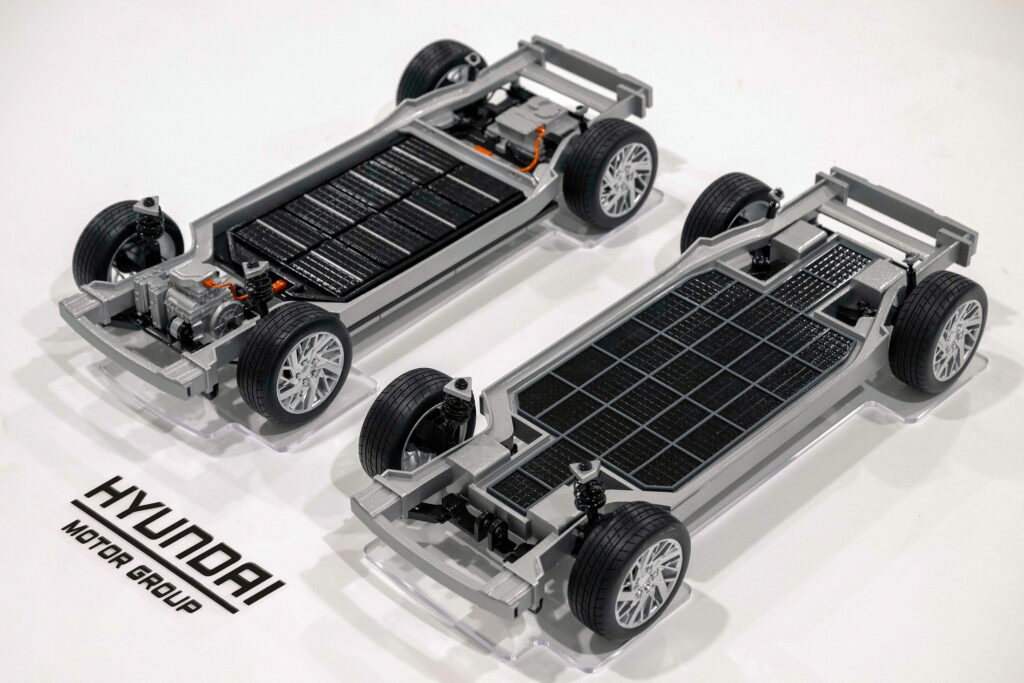

Last summer, BMW disclosed its development of a four-motor powertrain, currently undergoing testing in the i4 M50. This advanced powertrain is expected to find its way into the upcoming electric M3, likely built on BMW’s new Neue Klasse platform.

As of now, BMW has not provided a specific timeline for the release of the electric M3 or the introduction of a new electric 3 Series. Expectations suggest a wait of at least a couple of years. However, if the recent trademark is any indication, the electric M3 might don the distinctive iM3 moniker when it finally hits the market.