At the uppermost end of the car market, ‘best’ is rather subjective and those who spend a million ringgit and more would consider that what they have purchased is ‘the best’. Nevertheless, each carmaker in that sector would present its car as being the best and Bentley declares its Flying Spur as ‘the best luxury sedan in the world’.

The Flying Spur is now available through the officially importers for Malaysia, Bentley Kuala Lumpur, and is available in both 4-seat or 5-seat configurations. The basic price starts from RM839,000 excluding taxes and registration, and a typical customer would obviously pay a higher price.

Driver-centric experience

While most Bentley customers in Malaysia are likely to be chauffeur-driven, the company’s research shows that an increasing number of its customers prefer to drive the car themselves. In fact, global research (including two customer clinics in America and China) indicated that over 40% of customers travel with rear seat passengers at least once a week.

For this reason, Bentley’s engineers focussed on offering a more driver-centric experience, with a class-leading portfolio of intelligent and intuitive equipment and technology tailored to the driver and also the passengers.

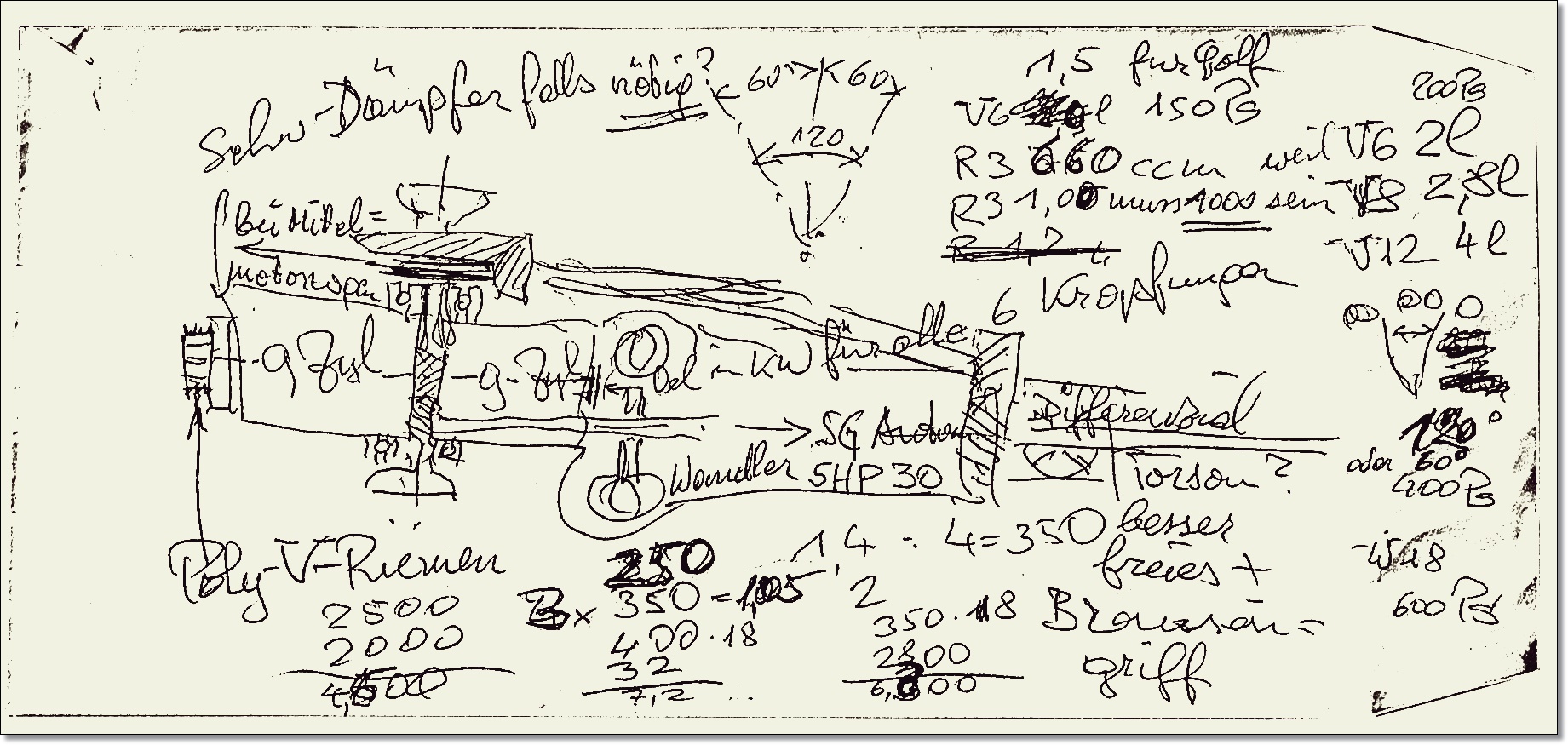

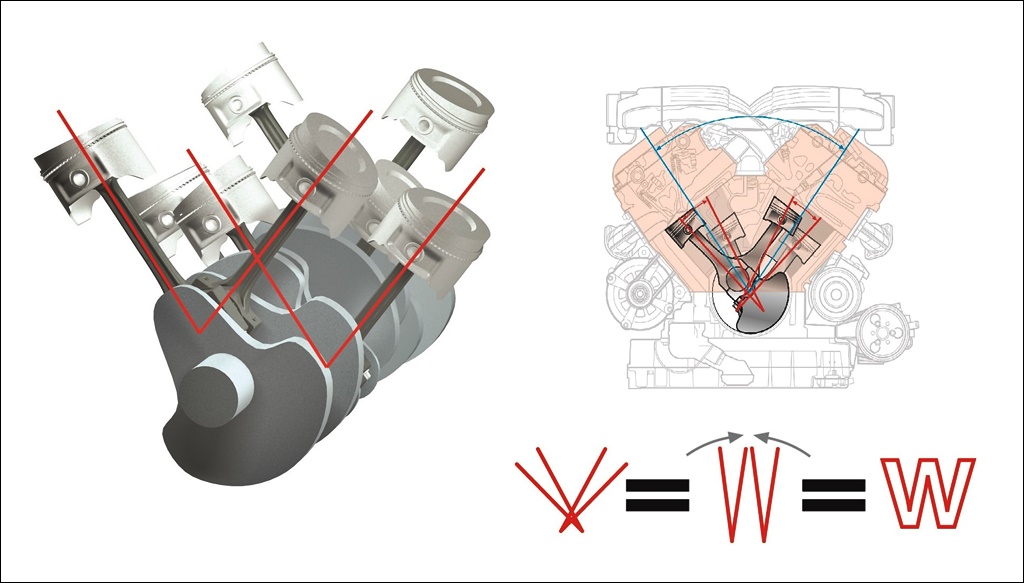

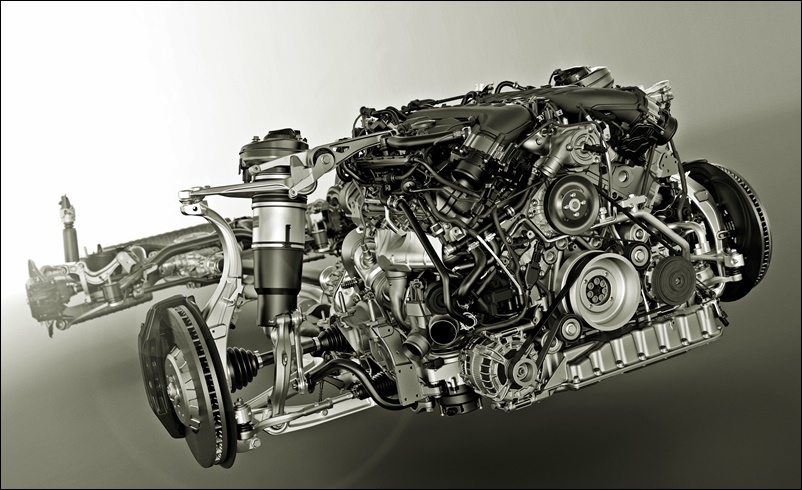

V8 that can become an I4

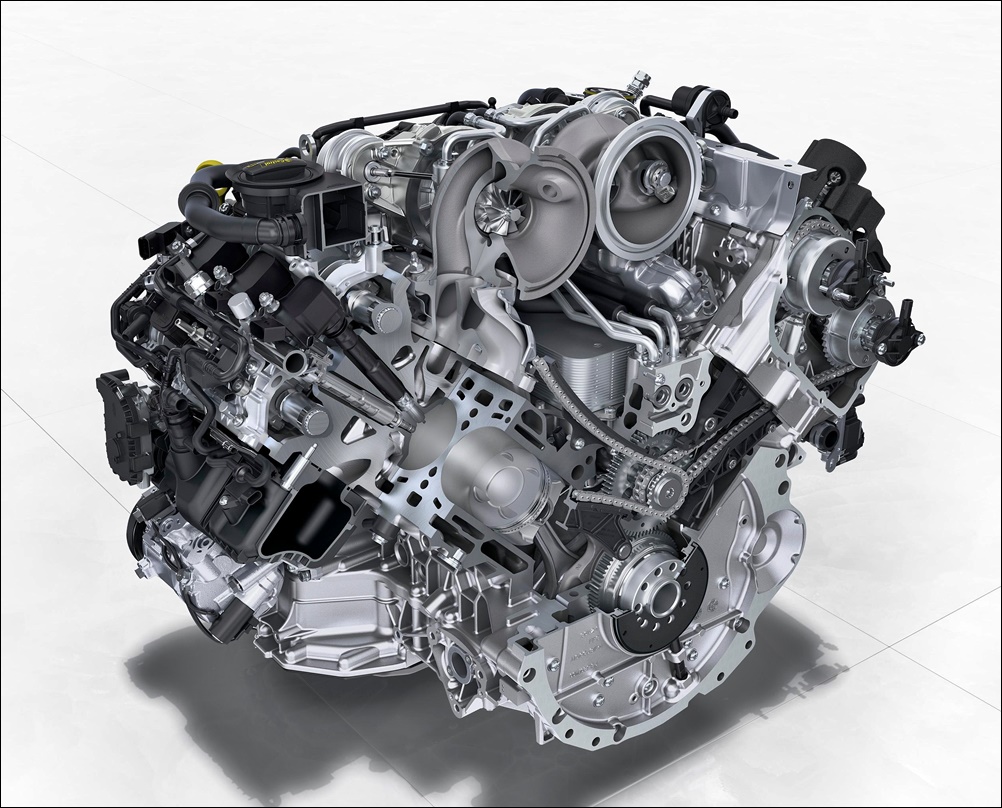

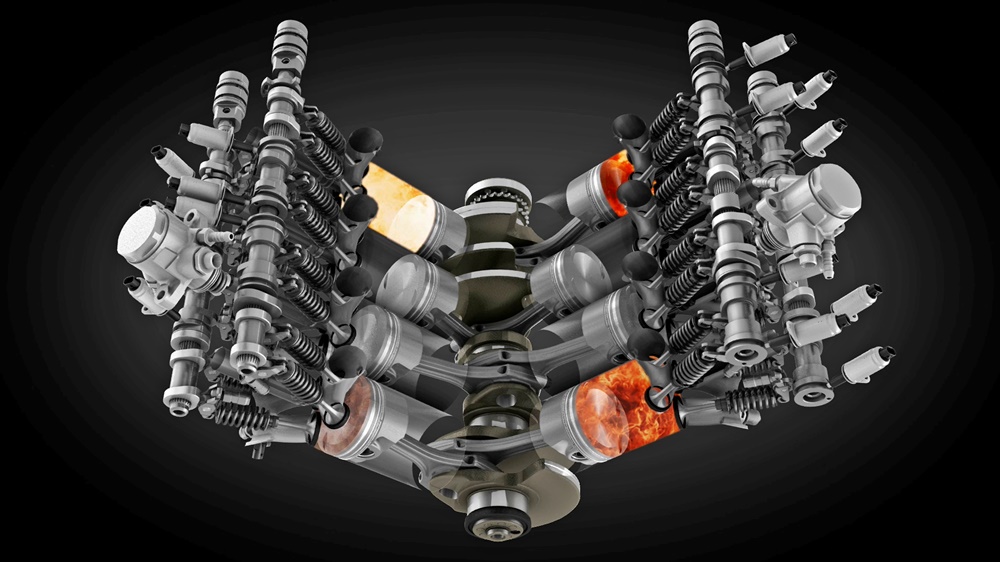

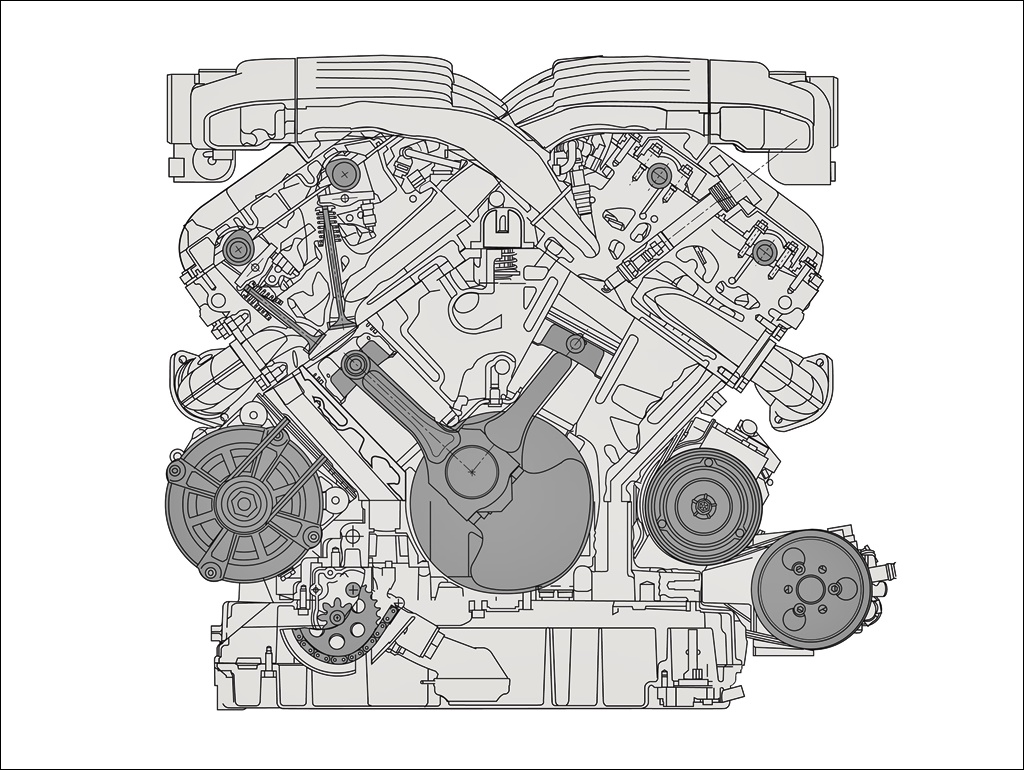

Under the bonnet is Bentley’s 4.0-litre, twin turbocharged V8 engine, an alternative choice to the iconic W12 unit. With turbocharging, it produces 550 ps/770 Nm with responsiveness and a top speed claimed to be 318 km/h.

When the driver is not blasting along at high speeds, the engine can save fuel by literally halving its displacement and running on 4 cylinders. It does this by shutting down one bank of cylinders under light-load conditions, when torque demand is below 235 Nm and the engine speed is below 3000 rpm.

The transition from V8 to what is essentially an inline four is imperceptible to the occupants and can be executed within 20 milliseconds (a tenth of the time it takes to blink). The result is savings of up to 16% in fuel consumption, allowing a longer range and less stops to refuel if driving very long distances.

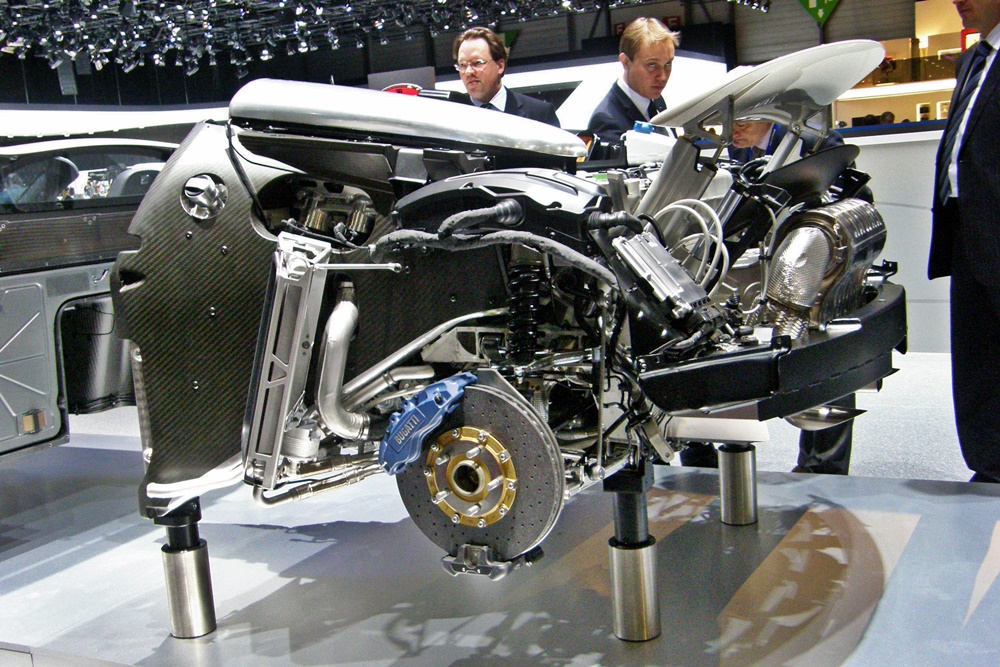

Advanced chassis

The latest Flying Spur has powertrain and chassis advancements; Adaptive Air Suspension, Torque Vectoring by Brake, Drive Dynamics Control, and Electric Steering, all of which are standard features. The technically advanced, adaptive chassis can feature Bentley’s pioneering 48V electric active anti-roll control system (Bentley Dynamic Ride) and Electronic All-Wheel Steering are available as options.

Recognisable as a Bentley

The bold exterior design is new and modern but still recognisable as a Bentley. It has increased road presence and stronger, more muscular lines that sweep the full length of the car. Compared to the second generation, the latest one has a wheelbase that is 130 mm longer, benefitting interior space and comfort.

For the Flying Spur V8, there are seven Bentley paint finishes to choose from and for those who want even more exclusivity, there is an extended range of over 60 colours, including Mulliner and personal commission.

Cabin with fine materials and craftsmanship

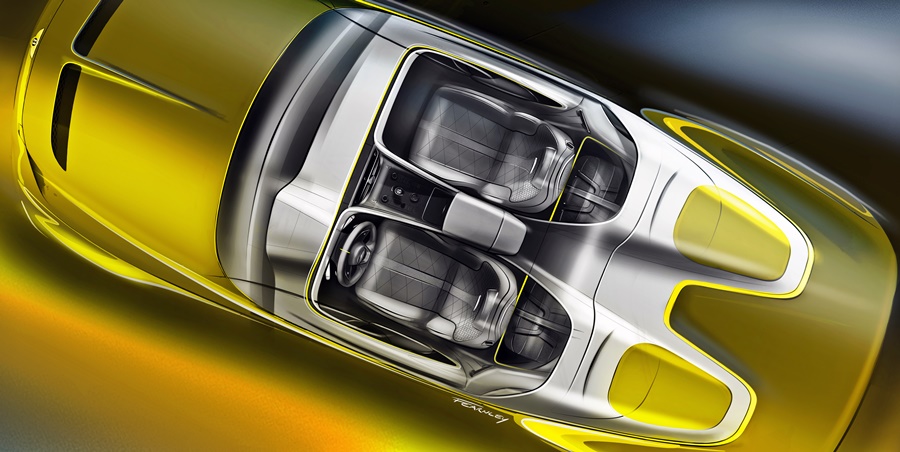

The interior has comfortable, spacious seats available in 5 hide colours, with Bentley’s ‘Wing’ theme across the lower console and fascia. Sweeping horizontal veneer flows across the dashboard and into the doors, emphasising the spacious width of the cabin. Besides Crown Cut Walnut as standard, there are 7 other veneers to choose from, plus a High Gloss Carbonfibre technical finish.

The industry-first Bentley Rotating Display is also available on the new Flying Spur V8. When the engine start button is pressed, the veneer section in the middle of the dashboard rotates to reveal a 12.3-inch touchscreen, displaying three, customisable digital tiles. The second side of the display reveals three elegant analogue dials showing outside temperature, a compass and a chronometer. A complete digital detox can be selected on the third side, to simply enjoy the seamless wood veneer fascia continuing around the cabin.

Needless to say, the range of equipment is extensive and can be supplemented with options like Rear Seat Entertainment tablets, Naim for Bentley audio system and even the luxury of an onboard 2-bottle drinks cooler. A completely new design means that the cooler is packaged into a much smaller space than the previous generation of the Flying Spur, resulting in less intrusion into the 420-litre boot space.

Only electric power for Bentley vehicles by the end of this decade