Nissan may be buffeted by financial problems at this time but new products still need to get into the market and even though the COVID-19 pandemic has slowed things down, the carmaker is continuing on the road forward.

That road is one which requires electric vehicles (EVs) and Nissan is ready with the all-new Ariya, a crossover SUV which, like the successful LEAF, is powered only by electricity. Introduced online to a global audience today from the new Nissan Pavilion in Yokohama, Japan, the Ariya will be priced at around 5 million yen (about RM200,000). It is scheduled to go on sale in Japan in mid-2021, with exports starting by the end of next year to Europe, North America and China.

“The Nissan Ariya is a truly beautiful and remarkable car,” said Nissan’s Chief Operating Officer, Ashwani Gupta. “It enables you to go further, easier and in comfort. The Ariya is designed to impress, and to express what Nissan strives for – making our customers’ lives better.”

New electrified brand identity

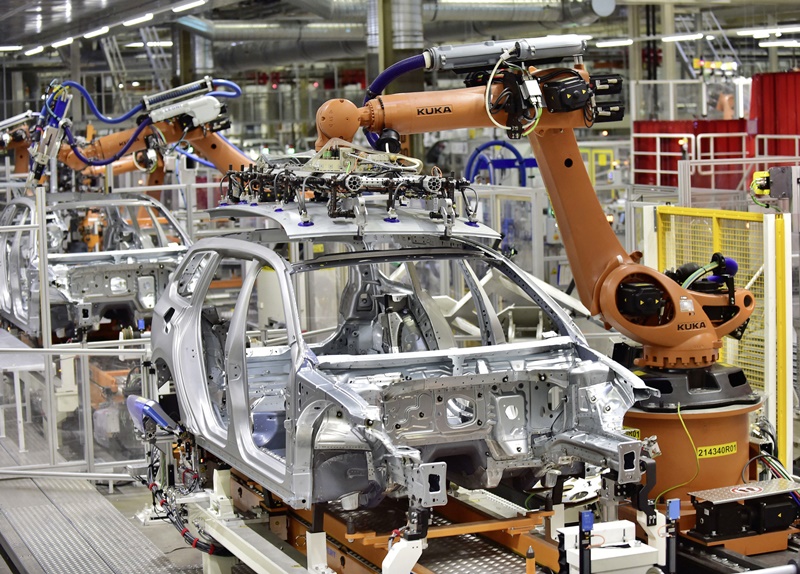

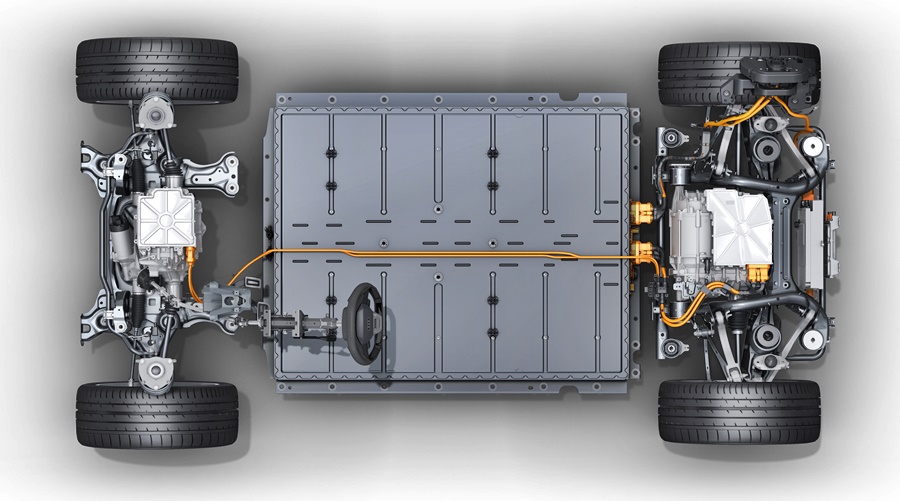

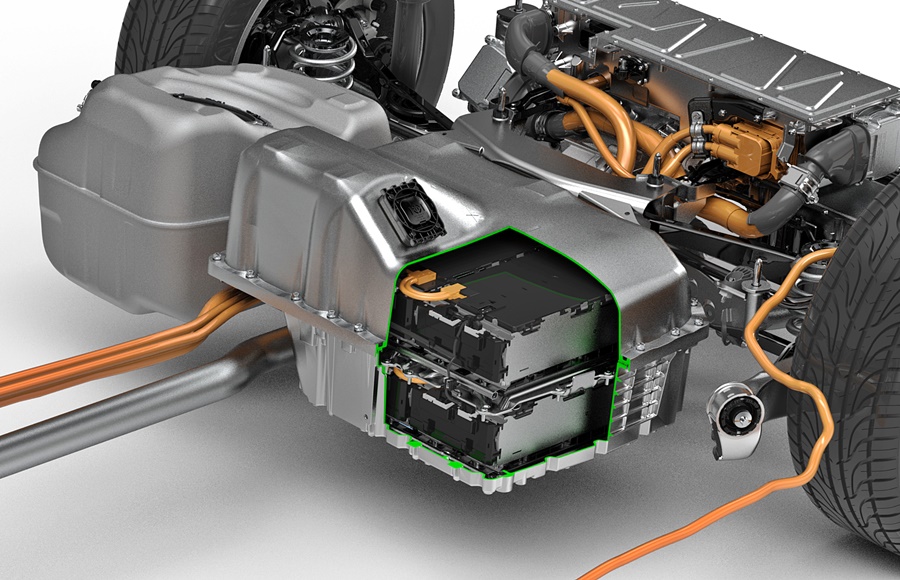

The Ariya is heavily based on the similarly-named concept vehicle displayed at the 2019 Tokyo Motor Show although the first design ideas started with the IMx at the 2017 Tokyo Motor Show. The first production model to represent Nissan’s new electrified brand identity, it utilizes an all-new Alliance-developed EV platform.

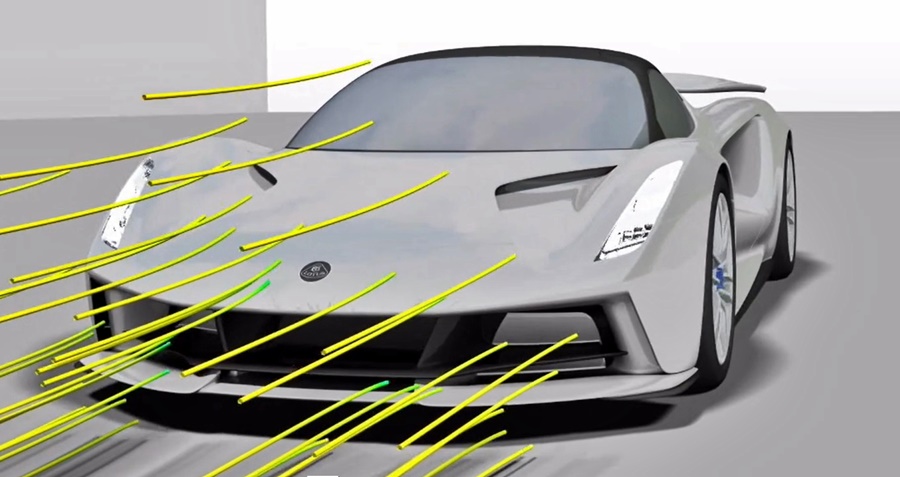

The styling adopts the company’s new design philosophy which is based on what Nissan calls ‘Timeless Japanese Futurism’ – a distinctive Japanese approach conveyed in a simple-yet-powerfully modern way. Embracing the Japanese term ‘iki’, which characterizes the Ariya’s chic, cutting-edge nature, the front of the vehicle appears seamless, elegant and fresh.

It’s highlighted by a shield – a new term for the traditional grille for the EV era. The shield, incorporating a 3-D, traditional Japanese kumiko pattern just under the smooth surface, protects sensing equipment used for ProPILOT functions and Intelligent Key detection without the aesthetics interrupting operation.

Redesigned brand logo

Nissan’s brand logo, which has been redesigned, is prominently placed at the centre of this aerodynamic shield, beaming with crisp definition from the 20 LEDs that compose it. The lower section of the shield is bordered by subtle lighting that illuminates, along with the logo, when the Ariya is ready for operation. Thin LED headlamps, constructed with four 20-mm mini-projectors, are combined with sequential turn signals to reinvent Nissan’s signature V-motion design.

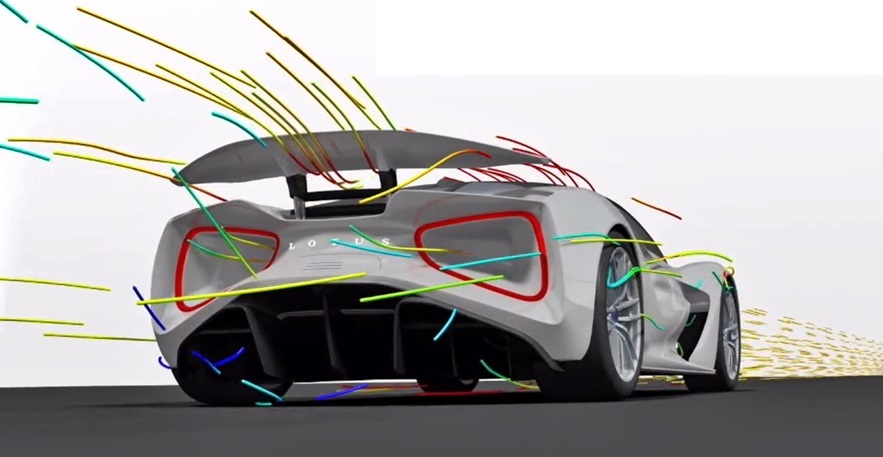

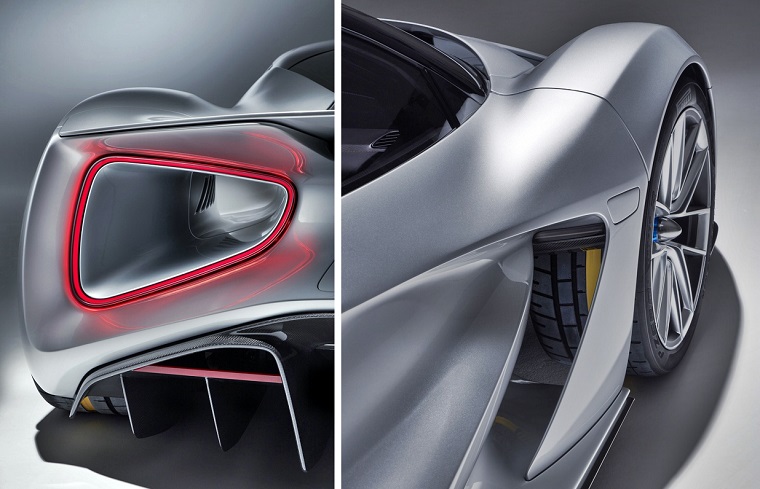

When viewed from the side, the Ariya has a single, uninterrupted horizon line that stretches across the side profile, linking the front fascia and the rear, conveys linear movement, creating architectural beauty in tension and drama from every angle.

The rear of the Ariya characterized by a steeply raked C-pillar that blends into the rear deck. The one-piece light blade, representing the rear combination lamps, has been engineered to give a black-out effect when parked, and a consistent red illumination, day or night, when in use. Rear fender flares and a high-mounted rear wing signal the Ariya’s powerful EV capabilities.

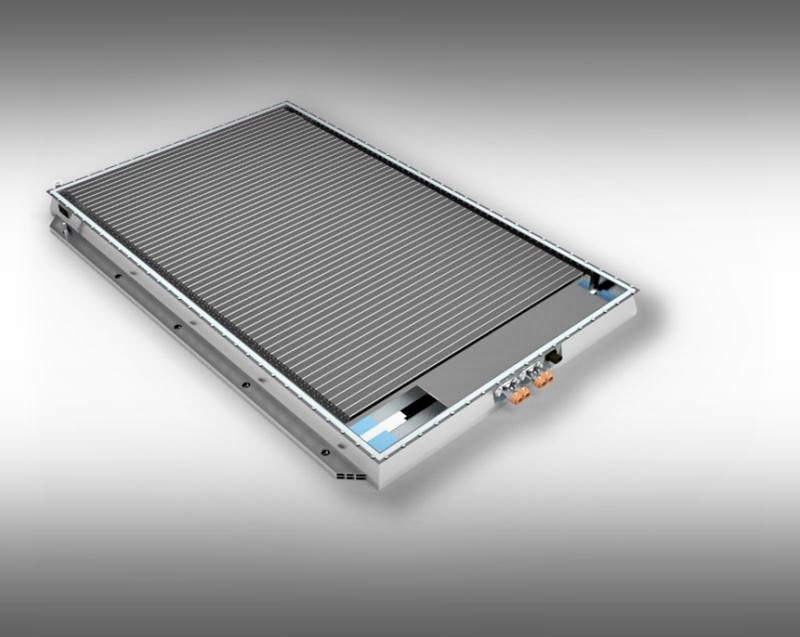

2WD and AWD, with two battery pack sizes

Building on Nissan’s strength as an EV pioneer, the Ariya is said to ‘take the powerful performance and capabilities of zero-emission vehicles to a new level’. Four core models are offered with choices of 2-wheel-drive (2WD) and all-wheel drive (AWD). Using peak 130 kW charging, the Ariya can recover up to 375 kms with a 30-minute quick charge using Japan’s CHAdeMO charging system.

The Ariya 2WD can be ordered with 63 kWh of usable battery capacity which is suitable for urban commuters, or a larger battery pack with 87 kWh which can provide additional range. The Ariya with the smaller battery pack has an output of 168 kW while the bigger one has 178 kW, with torque from standstill at 300 Nm for both versions. Factory testing has achieved up to 610 kms on a fully charged battery pack.

Like the 2WD variant, the Ariya AWD also has two choices of battery pack capacities – 63 kWh and 87 kWh. Output is 250 kW/560 Nm for the 63-kWh version and 290 kW/600 M, for the bigger battery pack. The latter has a top speed claim of 200 km/h.

With e-4ORCE AWD control technology and twin electric motors, Nissan claims it can deliver balanced, predictable power to all four wheels, equal to or better than many premium sportscars.

Vehicle pitch and dive are minimized by adding regenerative rear-motor braking to the usual front-motor regenerative braking employed by typical EV and hybrid systems today. In addition to optimizing front and rear torque allocation, the system applies independent brake control at each of the four wheels to maximize the cornering force generated by each one. This delivers cornering that faithfully follows driver intentions with minimal steering adjustments.

“By taking advantage of e-4ORCE’s precise motor control response, we’re able to control vehicle motion as soon as the brakes are applied for a stable, smooth ride,” said Ryozo Hiraku, expert leader of Nissan’s powertrain and EV engineering division.

Most technologically advanced Nissan car

The Ariya is also the most technologically advanced Nissan car to date, especially with its ProPILOT 2.0 advanced driver assistance system and ProPILOT Remote Park and e-Pedal features.

The e-Pedal, first introduced in the LEAF, allows the driver to launch, accelerate and decelerate using only the accelerator pedal. It works by initiating the electric motor to start the deceleration process of the vehicle when easing off the accelerator pedal. On low-traction surfaces, the brakes are applied simultaneously with the motor, allowing all four wheels to safely slow down the vehicle. On models equipped with e-4ORCE, regenerative torque is distributed not only to the front wheels, but also the rear.

Also standard across the Ariya line-up is Nissan’s Safety Shield system. This includes Intelligent Around View Monitor, Intelligent Forward Collision Warning, Intelligent Emergency Braking and Rear Automatic Emergency Braking technology.

‘Like a cafe lounge on a starship’

The interior is described as being more akin to a sleek cafe lounge on a starship, evoking performance and intrigue, than to a traditional automotive cabin. The advantages provided by the new EV platform enabled the interior designers to create the most spacious cabin in its class.

This is also helped by the compact nature of the powertrain components which made it possible for the engineers to install the climate control system under the bonnet (where a traditional gasoline engine would be). This meant that the whole length of the cabin could be utilized without obstructions, such as a transmission tunnel or cabin systems tucked under the instrument panel.

Also, a flat, open floor – made possible by the location of the battery at the base of the chassis – and the Ariya’s slim profile Zero Gravity seats result in vast amounts of legroom and easy interaction between front and rear passengers.

The Ariya’s minimalist dashboard has no buttons and switches, something which is unique. The primary climate control functions are integrated into the wooden centre dash in the form of capacitive haptic switches that offer the same feeling as mechanical switches by vibrating when touched.

The display interface features both a 12.3-inch instrument monitor and 12.3-inch centre display along a single horizon. By displaying multiple facets of information on one horizontal plane, information can be quickly digested without the driver being distracted from the road. The two displays are oriented in a wave-like shape to ensure important vehicle information, such as battery information, range and navigation, can be easily reached and scrolled through with a simple swipe.

Related story: Why Nissan designers avoided the tablet in yhe Ariya Concept

The Ariya is the first Nissan model which can received firmware updates over the air using Remote Software Upgrade. The technology automatically updates various software inside the vehicle, making it unnecessary for the owner to take the car to a service centre. With periodic real-time updates, the Ariya will always be able to operate at its full potential.

DIMENSIONS OF THE ARIYA

Overall length – 4595 mm

Overall width – 1850 mm

Overall height – 1655 mm

Wheelbase – 2775 mm

Kerb weight – 1,900 kgs to 2,200 kgs

The Ariya will only go on sale in 2021 and only in Japan and certain regions, and Malaysia is not included. However, you can own a fully electric EV now as the Nissan LEAF is available in Malaysia. Visit www.nissan.com.my to find out where you can get the EV experience.

Nissan IMk concept EV – the perfect city car of the future? (w/VIDEO)