Renault menerusi pasukan Penyelidikan dan Pembangunan (R&D) di China kini bekerjasama rapat dengan Geely bagi membangunkan rangkaian Kenderaan Tenaga Baharu (NEV) yang menyasarkan pasaran Asia Tenggara dan Amerika Latin. Langkah ini dianggap signifikan kerana buat pertama kali Geely berkongsi platform utama Global Energy Architecture (GEA) dengan pengeluar automotif lain.

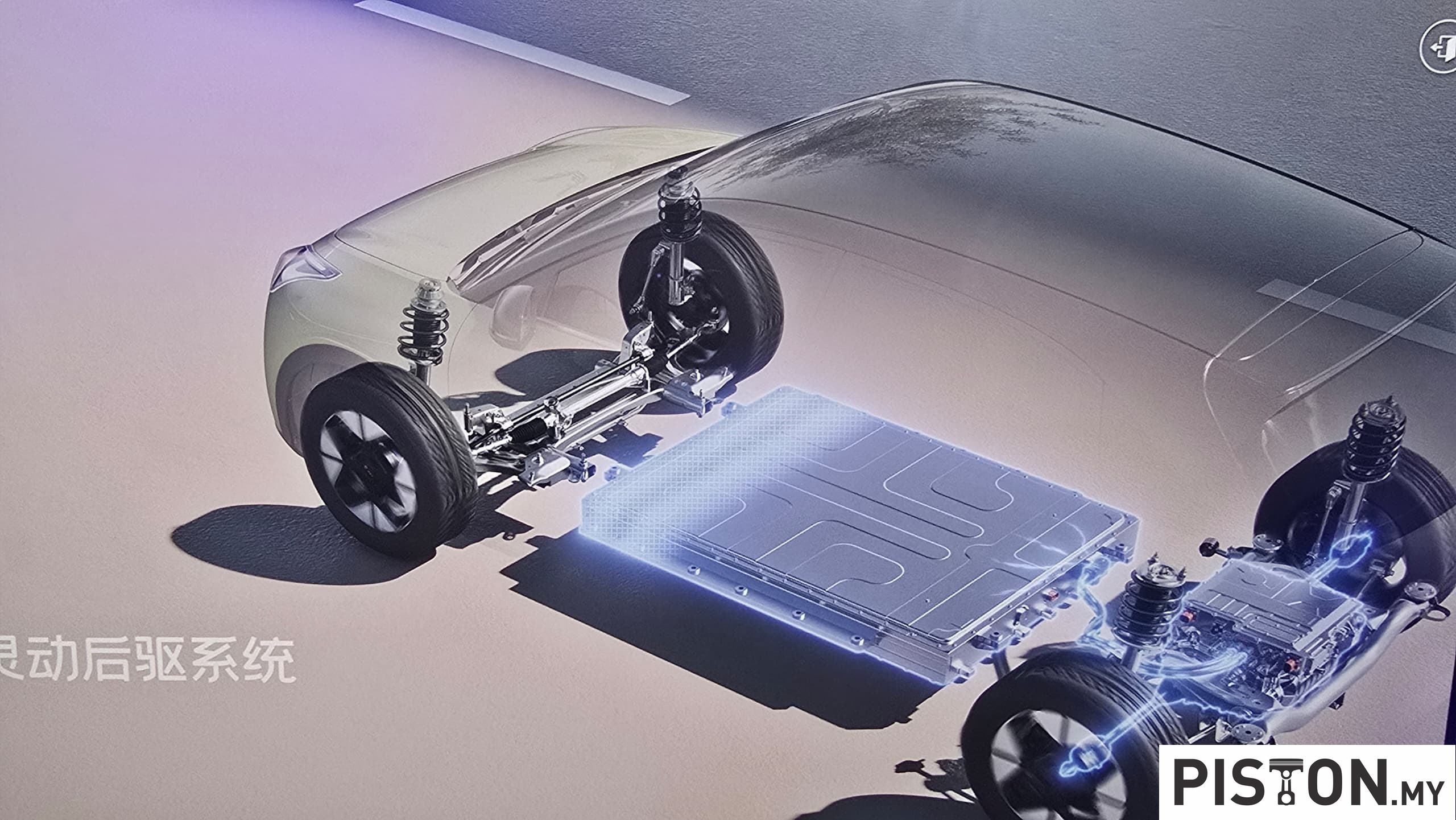

Model-model baharu ini akan merangkumi SUV hibrid elektrik dan juga versi elektrik sepenuhnya. Renault akan bertanggungjawab terhadap rekaan luaran, manakala sistem casis dan seni bina kenderaan akan menggunakan teknologi daripada model Geely Galaxy. Pendekatan ini dijangka dapat mengurangkan kos, mempercepatkan proses pembangunan, serta mempercepatkan kemasukan ke pasaran sasaran.

Walaupun Renault menumpukan perhatian kepada pembangunan kenderaan elektrik bersaiz kecil untuk pasaran Eropah, SUV berasaskan platform Geely ini akan dipasarkan di Korea Selatan, Asia Tenggara, Amerika Latin dan Afrika Utara. Reputasi kukuh Renault serta rangkaian pengedarnya yang meluas di rantau-rantau ini dijangka memberi kelebihan daya saing, manakala Geely pula mendapat manfaat daripada akses kepada infrastruktur jualan dan selepas jualan yang mantap.