A few months ago, Geely offered a glimpse into the future of alternative fuel technology with winter testing of a cutting-edge super sedan powered by a methanol engine. Based on the Binrui Cool platform, this prototype replaces the traditional BHE15-EFZ petrol engine with the experimental DHE20TDM diesel unit, designed to run on M100 (100% methanol) fuel.

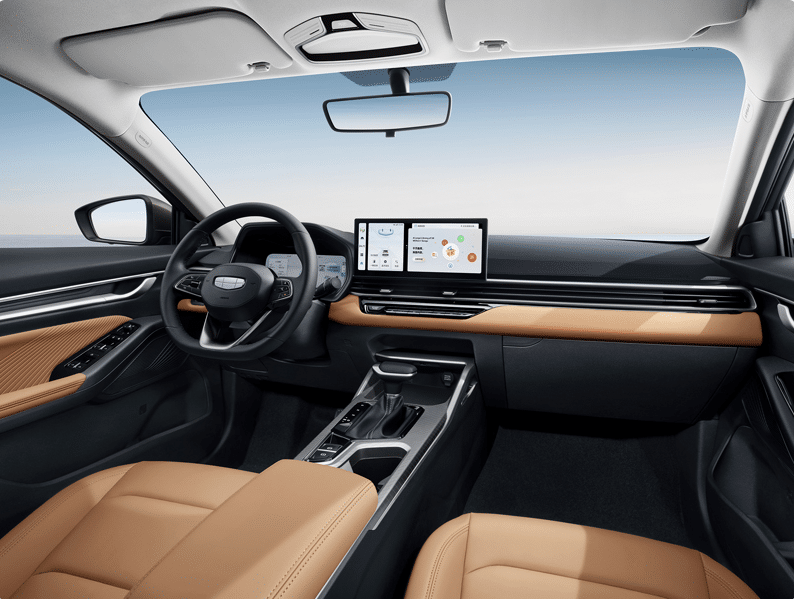

The innovative car made a public appearance at Auto Shanghai 2025, giving visitors an up-close look at what could be the next evolution in renewable energy for high-performance cars.

Geely’s methanol prototype delivers a thermal efficiency of 46%—a figure that rivals the best in internal combustion technology—alongside an impressive 15:1 compression ratio. It produces 250hp and a peak torque of 400Nm.

Most notably, despite being a high-performance concept vehicle, this methanol-fueled engine meets China’s stringent China VI-B emissions standards, which are equivalent to the Euro 6d regulations in Europe. This highlights methanol’s potential as a clean-burning alternative to traditional fossil fuels.

Geely is not just experimenting with green power for the road. The company has announced plans to launch the Super Cup Pro racing series in 2026, featuring a monocup format with identical methanol-powered race cars. This initiative underlines Geely’s belief that motorsport can lead the transition to renewable energy, proving that speed and sustainability can coexist.

Looking ahead, Geely envisions methanol as a viable fuel for commercial transportation. The company is developing a hybrid concept that combines methanol-fueled internal combustion engines with electric drivetrains, potentially offering a clean and efficient alternative to conventional diesel-powered vehicles.

To support this vision, Geely is planning to build a methanol production facility in Inner Mongolia, capable of producing 50,000 tons annually. This significant infrastructure investment reaffirms the company’s long-term commitment to alcohol-based fuels—a journey that began in 2005 under the leadership of Chairman Li Shufu, who continues to champion this technology as a key part of Geely’s sustainability strategy.