Chinese automotive giant Geely Auto made headlines at Auto Shanghai 2025 with the global unveiling of its advanced Galaxy Cruiser SUV prototype, alongside a suite of major innovations in vehicle safety and battery technology. The presentation underscored Geely’s vision for the future of intelligent and sustainable mobility, with a firm emphasis on safety and accessibility through technological progress.

The Galaxy Cruiser, described by the company as a robust and technologically advanced SUV, serves as a bold statement of intent. The prototype introduces a number of industry-first capabilities that blend off-road resilience with smart connectivity. It is the first vehicle in its class capable of switching in real time between pure electric, hybrid, and extended-range power modes, aided by an AI-controlled four-wheel drive system designed to handle diverse terrains and unpredictable driving environments. This system allows the SUV to effortlessly transition from urban commuting to challenging off-road conditions.

Equipped with what Geely refers to as a full-power digital chassis, the Galaxy Cruiser features a range of dynamic functions typically reserved for specialised off-road or military vehicles. It can perform crab walking, rotate on the spot, continue driving with a flat tyre, and even drift autonomously. Notably, it has been engineered to remain buoyant on water for up to two hours at a speed exceeding 8.5 km/h and can wade through water up to 800 mm deep.

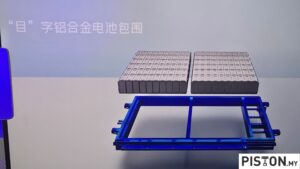

Central to the Galaxy Cruiser’s innovation is Geely’s newly developed Golden Short Blade Battery, which the company says is built for extreme resilience. This battery is designed with patented bulletproof materials and special coatings to prevent thermal runaway, deformation, or explosion. In addition to powering the vehicle’s intelligent systems, it is also integrated with Geely’s satellite connectivity technology to ensure stable communication even in remote areas.

As part of its larger battery strategy, Geely also announced the formation of a new industrial battery group, JiYaoTongXing, which consolidates its existing battery technologies under one brand—the Golden Short Blade Battery. The new entity will focus on improving battery energy density, safety, and rapid charging capabilities, all while aligning with China’s newly implemented national standards for battery impact resistance. Geely confirmed it will contribute to wider industry adoption by making its patented battery pack bottom impact testing equipment freely available.

In a landmark step towards industry-wide safety standardisation, Geely introduced the Geely Global Safety Centre, described as the largest standalone automotive safety laboratory in the world. The facility will open its doors not just to Geely’s brands, but to other automotive manufacturers and researchers. With this initiative, the company seeks to foster greater collaboration across the industry and accelerate the pace of innovation in vehicle safety.

Geely also used the Auto Shanghai platform to reinforce its broader strategic outlook. Operating under the theme “AI for All, All for Safety,” the company emphasised that safety should be an accessible and non-negotiable standard across all vehicle classes. It argued that cutting-edge technologies, including artificial intelligence and smart mobility platforms, must be leveraged to serve the public good, not just luxury segments.

The Galaxy Cruiser and the supporting infrastructure unveiled at Auto Shanghai represent more than just an ambitious product showcase. They reflect Geely’s determination to redefine the future of mobility by uniting electrification, artificial intelligence, and a profound commitment to safety. In doing so, the company positions itself not only as a leader in Chinese automotive innovation but also as a key player shaping the global conversation around next-generation transport.

If successful, Geely’s technological ambitions—including its new battery platform and global safety laboratory—could signal a shift in how the industry approaches both innovation and competition. With a focus on open collaboration, adaptability, and resilience, Geely is betting on a future where the road ahead is not just electric, but also safer, smarter, and shared.