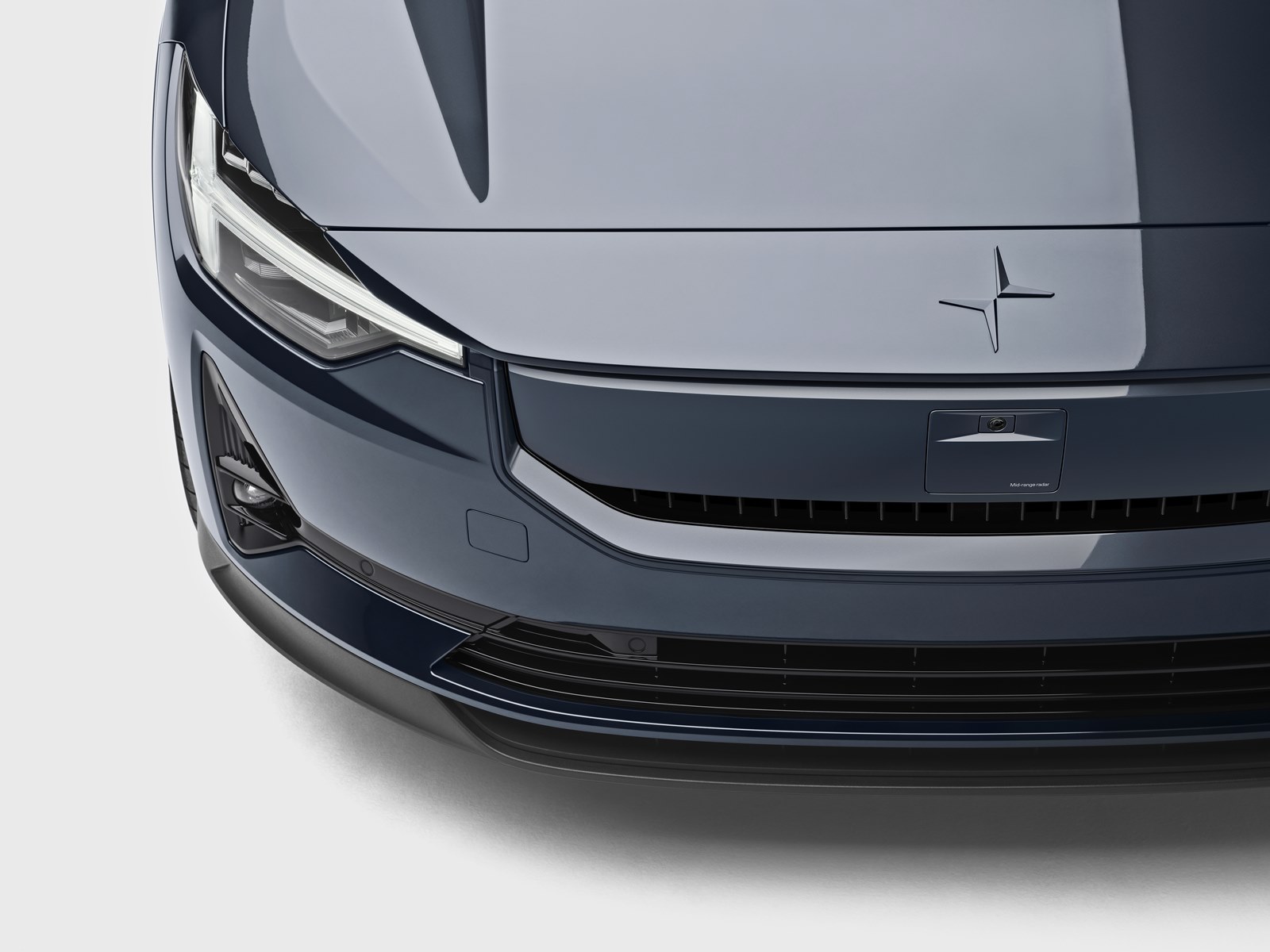

Polestar, the Swedish car company which makes and sells on battery electric vehicles (BEVs), will hold the world premiere for its next model, the Polestar 3, this October. This will be a SUV, the company’s first, and reflects the significance of the segment which is the most competitive today. Polestar will be entering one of the highest margin and growth segments in the automotive industry, particularly in the USA.

Customers can expect to order Polestar 3 in initial launch markets from the day of the premiere. Production is expected to begin in early 2023, and besides China, the model will be manufactured in the USA. This follows carmakers like Mercedes-Benz and BMW which set up factories for their first SUVs in the USA in the 1990s.

“This is a major milestone for our company, one that boosts our growth trajectory and takes us into our next phase,” said Thomas Ingenlath, Polestar’s CEO. “Polestar 3 is the SUV for the electric age. Our design identity evolves with this high-end large luxury EV, with a strong, individual brand character. With this car, we bring the ‘sport’ back to the SUV, staying true to our performance roots.”

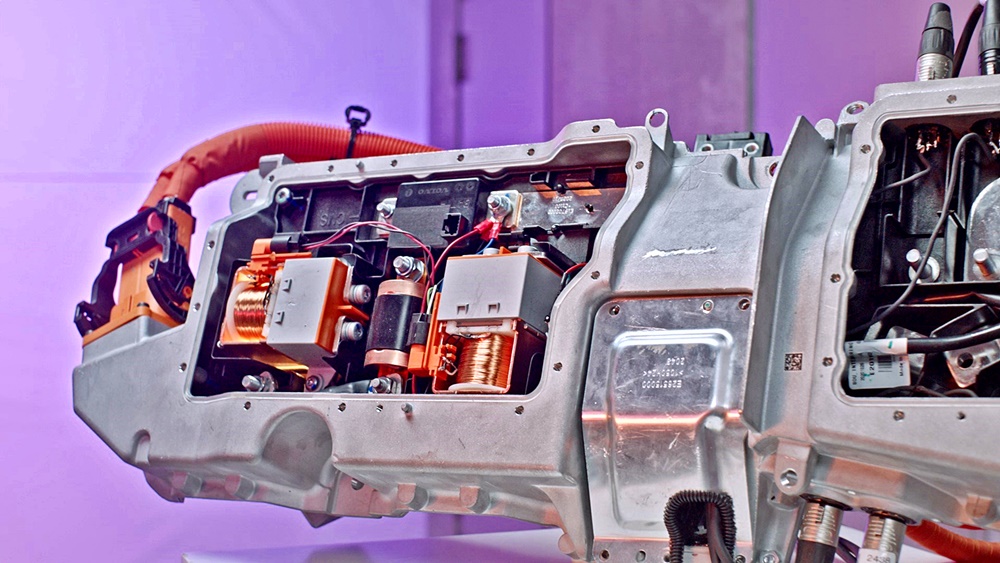

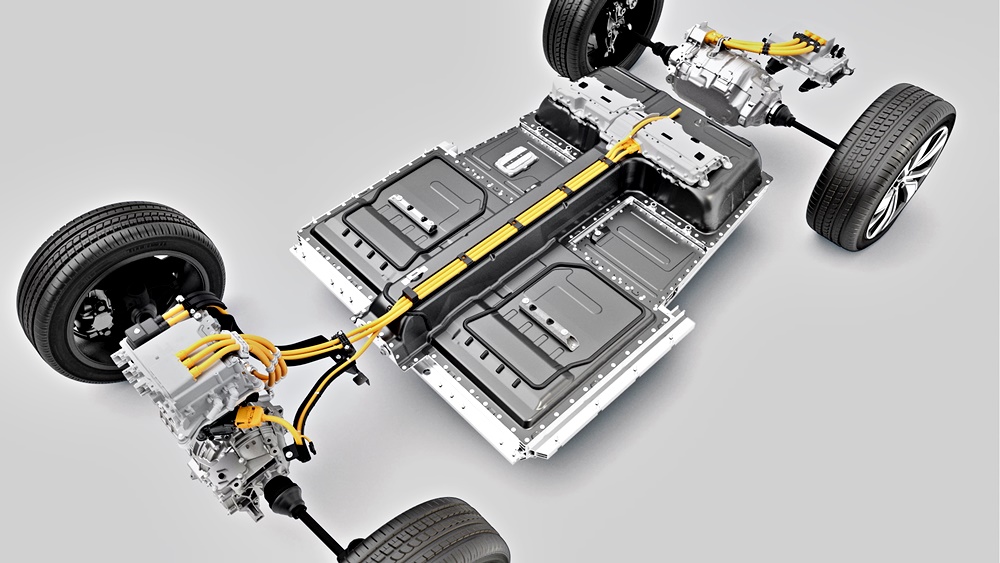

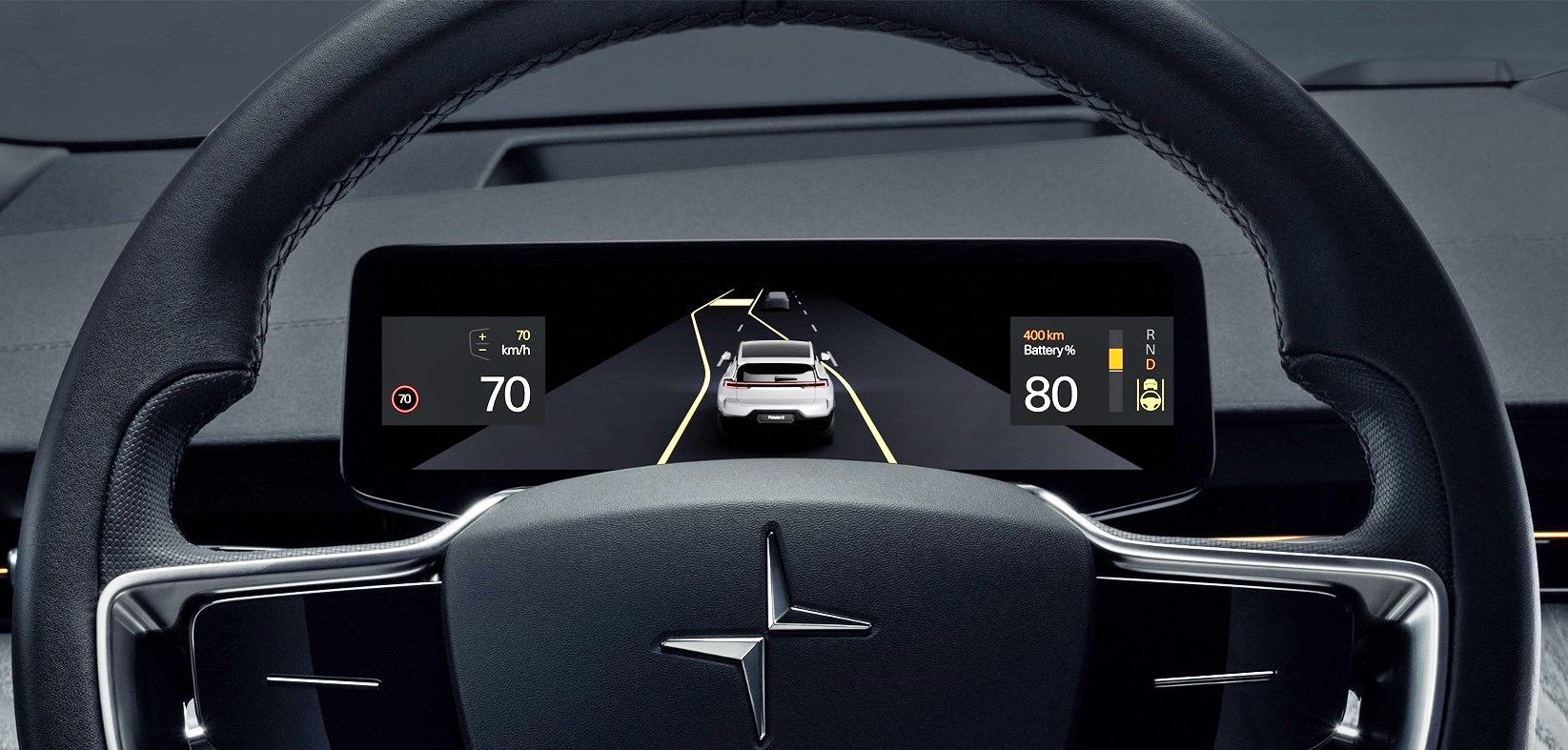

The company said that Polestar 3 will, over time, offer autonomous highway piloting powered by the best-in-class LiDAR sensor from Luminar and centralized NVIDIA computing power. At launch, it will have a dual-motor drivetrain for all-wheel drive and a large battery, with a range target of over 600 kms.

Polestar plans to launch a new model every year for the next 3 years, starting with Polestar 3. Polestar 4 is expected to follow in 2023, and it will be a smaller SUV coupe. In 2024, the Polestar 5 performance 4-door GT is expected to debut as the production evolution of Polestar Precept.

While Polestar is a recognised carmaker today, its origins were rather unusual as it started off as the name of a racing team in 1996. It gained prominence in the Swedish Touring Car Championship running Volvos and by 2015, Volvo Cars decided to take it in and give it a role involving high performance products.

With Volvo Cars being acquired by the Geely Group in 2010, Polestar also became part of the group while its racing activities have been run by Cyan Racing. Under the Geely Group, Polestar grew further and besides developing and selling electric performance cars, it offers performance hardware upgrades and engine software optimisations for Volvo models through their Polestar Engineered division.

Polestar also functions as an innovation lab for Volvo Cars, developing designs and technologies. Being part of a huge group, Polestar enjoys technological and engineering synergies and benefits from significant economies of scale as a result, as well as sharing resources. Polestar has production facilities in China, and as mentioned earlier, there will be a new factory in the USA to manufacture the new SUV model.

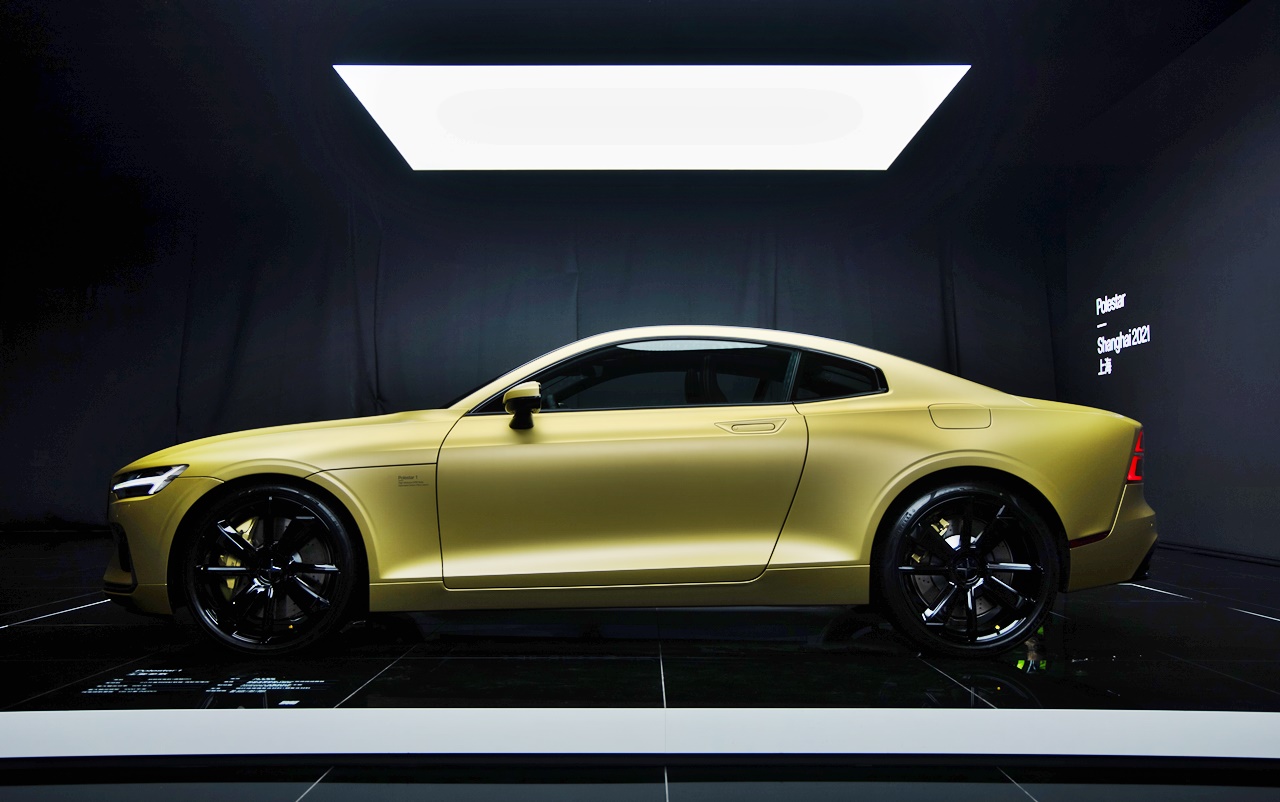

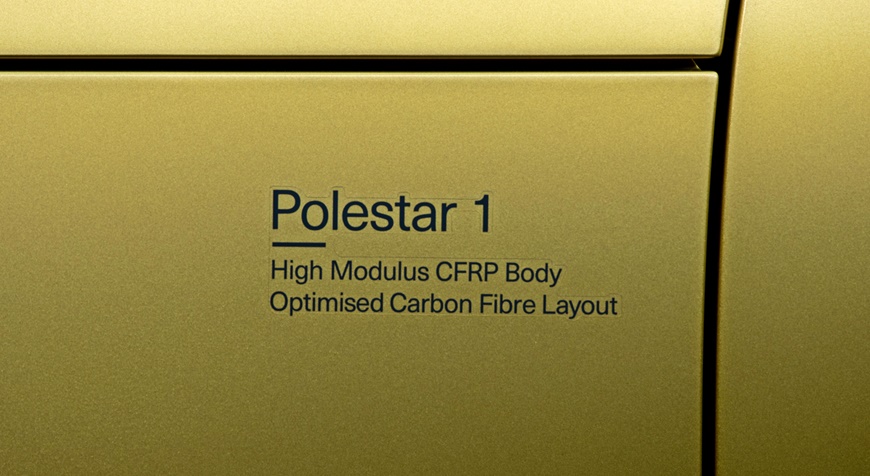

To date, Polestar has produced two models – the Polestar 1 which was built between 2019 and 2021 as a low-volume electric performance hybrid GT with a carbonfibre body, and the Polestar 2 which sells in larger volumes.

The company plans to increase its presence to at least 30 global markets by the end of next year. This supports its plans to grow ten-fold from global sales of approximately 29,000 in 2021 to approximately 290,000 by the end of 2025.

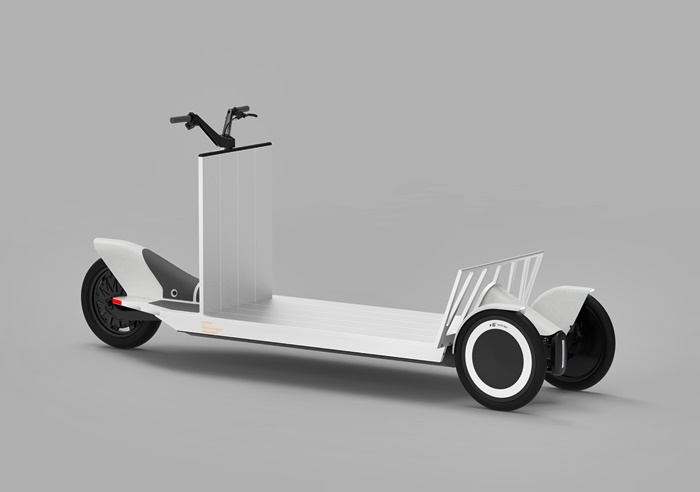

Polestar O2 concept shows that sportscars will still exist in the electric age