With the success story of the GR Yaris, it’s not surprising that Toyota has now followed up with another model and this time, it’s not on a limited production run. It’s the GR Corolla that has long been rumoured and it’s a full-fledged GR model developed from scratch rather than adapted from existing models. As with other GR models, which started with the Supra, the GR Corolla has been developed with a strong focus on high performance that will make it competitive for motorsport.

And with the company president, Akio Toyoda, being passionate about racing and being a racing driver himself, the engineers must have had a lot of encouragement and perhaps even given a bit of freedom in the budget. Naturally, the boss himself got involved in development and ensured that the final product would be as impressive as the GR Yaris.

100 bhp per cylinder

Under the bonnet is the familiar G16E-GTS turbocharged, direct/port injected 3-cylinder engine, first seen in the GR Yaris. For GR Corolla, the output from the 1681 cc engine is boosted to 300 bhp/307 Nm, which equates to an impressive 100 bhp per cylinder. The boost in power is partly due to using a 3-piece muffler which reduces exhaust pressure (and outside noise), which are essential to backpressure performance.

As would be expected, the compact and lightweight G16E benefits has technologies from TOYOTA GAZOO Racing’s long and broad racing experience – and successful too. Features include multi-oil jet piston cooling, large-diameter exhaust valves and a part-machined intake port. Combustion is fed by Toyota’s D-4S direct and port fuel injection system, which operates at high pressure for maximum fuel dispersion and efficiency.

The 12-valve engine uses a single-scroll ball-bearing turbocharger integrated in the exhaust manifold, reducing weight, while control of wastegate bypass gases is used to improve the catalyst’s warm-up efficiency.

Delighting drivers is the provision of a 6-speed manual transmission – and only a manual transmission. ‘Morizo’ (Toyota President Akio Toyoda’s racing name) probably approved and encouraged that, being a racing driver himself. It’s called an Intelligent Manual Transmission (iMT) though it is not explained what the ‘intelligent part is, although Toyota says the rev-matching is engineered to accommodate high torque levels.

Toyota has long experience with high-performance 4-wheel drive since its days with the Supra GT-Four and with experience gained in WRC participation, it has advanced its all-wheel drive technologies. These technologies are used in the GR Corolla’s GR-Four All-Wheel-Drive system which was originally developed for rallying. The system gives drivers a choice of 60:40, 50:50 or 30:70 power distribution to the front and rear wheels with the twist of a dial.

The GR Corolla Circuit Edition (limited production run) is also equipped with front and rear Torsen Limited-Slip Differentials, for further enhancement of cornering performance and grip. Left and right-hand drive torque distribution are more effectively controlled on the front and rear axles.

Wide and rigid for superior dynamics

To fully use all the power (and also to be worthy of the GR badge), the GR Corolla has a specially constructed bodyshell that is highly rigid. Based off the GA-C platform with Toyota New Generation Architecture (TNGA), its increased rigidity comes from significantly more weld points in the frame, particularly to strengthen joints. Further gains are made through extensive use of structural adhesive, increasing the joint rigidity between component parts.

The front suspension is a straightforward MacPherson-type strut with circuit-tuned coil springs, shock absorbers and stabilizer bars, For the rear suspension, there is a double-wishbone type multilink system that accommodates the AWD system’s goal of maximum agility and stability.

Wide tyres are installed for maximum cornering grip and high speed stability. Standard rubber provided from the factory are Michelin Pilot Sport 4 tyres sized 235/40R18 on 18-inch gloss-black 15-spoke cast alloy wheels.

Braking power comes from opposed, fixed-caliper disc brakes with 14 x 1.1-inch ventilated and slotted rotors clamped by 4-piston aluminium calipers. At the rear are 11.7-inch x 0.7-in. ventilated rotors with 2-piston aluminium fixed-caliper disc brakes.

Light and aerodynamic

Like the GR Yaris, there has been a focus on saving weight to maximize the performance potential, without compromising strength and safety, of course. This rigorous approach is particularly evident in the car’s construction, with extensive use of lightweight metals and materials used in key areas. Aluminium is used for the bonnet and front door panels, with light and strong high-tensile steel in critical areas to ensure the car’s structure can safely absorb and dissipate impact forces.

On the Circuit Edition, the roof is made of a forged (rather than woven) carbonfibre sheet molding compound. This lightweight, highly rigid material cuts weight and helps lower the car’s centre of gravity. The lower centre of gravity, which benefits stability and handling, is also a feature of the TNGA platform.

Aerodynamics are also vital for performance and it’s not just on the circuit but also in rallies as the speeds are also very high (not to mention literally flying through the air). From competition experience, the engineers have designed the GR Corolla with optimum aerodynamic efficiency. As with rally cars, the shaping of the front and rear canards and lower rockers efficiently channel airflow down the sides of the car. Bonnet, fender and rear bumper ducts and a flat underfloor reduce drag, add downforce and improve stability. Wind flow is directed onto the rear spoiler to generate extra downforce.

The exterior design of the GR Corolla follows that of the GR Yaris with its wide stance and hatchback form. The Core Grade’s aluminium bonnet is matched with a colour-keyed roof and matching shark-fin antenna, while the Circuit Edition features a bonnet bulge with functional gloss-black air ducts.

At the rear, a lower bumper cover with functional air vents. The wide track and flaring of the rear wings emphasize the car’s wide and low silhouette, with a spoiler on the roof to control airflow as it departs from the roof.

Race-inspired interior

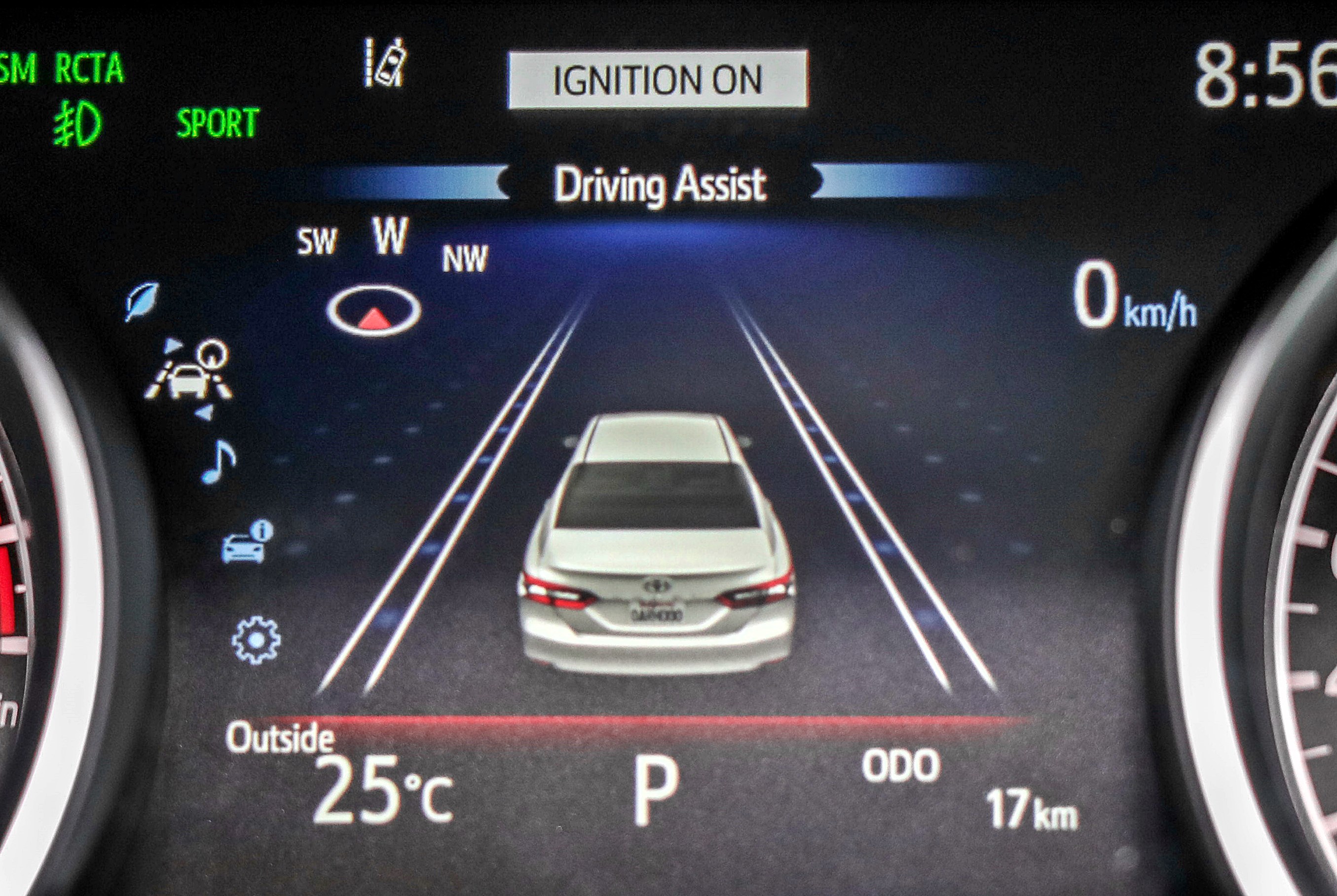

The GR Corolla’s interior is very functional, thanks to feedback from professional drivers who obviously wanted a true driver’s cockpit. Facing the driver is a GR Full TFT meter with a 12.3-inch colour Multi-Information Display that has a GR meter with 4WD mode, turbo pressure, gear position indicator and tachometer.

The shift lever has a shortened stroke for a quick throw between gears. The subject of much testing, it is positioned where the driver’s arm is naturally lowered from steering. The action is light with short shift strokes. A pull-type mechanical parking brake is still used, something which is slowly disappearing as electric parking brakes replace the simple mechanical system. Incidentally, for the Circuit Edition, the shifter knob has an exclusive ’Morizo’ signature.

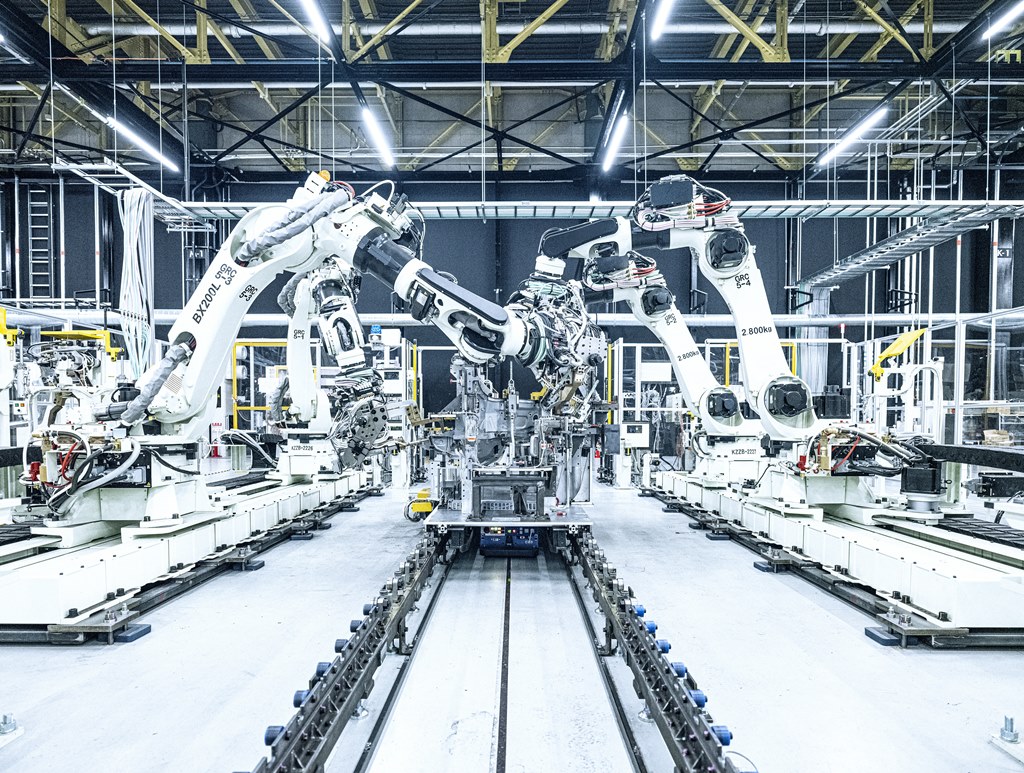

The GR Factory

The GR Corolla is built at the Motomachi plant in Japan, where as the Lexus LFA and Supra A80 have been built. It has a dedicated GR production line which has also produce the GR Yaris. Instead of the traditional conveyor system, the body and assembly lines comprise several different cells connected by automatic guided vehicles rather than the conveyors featured in conventional car plants. This fully flexible method of working, with many manual assembly techniques, enables precise body and suspension alignment, with variations in vehicle dimensions and weight kept to a minimum.

While the assembly of each GR Corolla takes longer than a conventional mass-produced car, the production line has been streamlined for performance, TOYOTA GAZOO Racing has brought together highly skilled technicians from throughout the company to work on the new model. This team not only assembles the GR Corolla but also contributes to the technical skills of workers at other Toyota facilities.

The pricing has not been announced though whatever price it has, there will undoubtedly be no shortage of buyers. While the GR Yaris was a limited run, the GR Corolla will be produced in larger numbers as it will also be sold in North America (which did not get the GR Yaris).